Contruction Starts on World's Biggest Offshore Floating Facility

At 1601 ft. long x 242.7 ft. wide, the Prelude FLNG facility will be the largest offshore floating facility ever built.

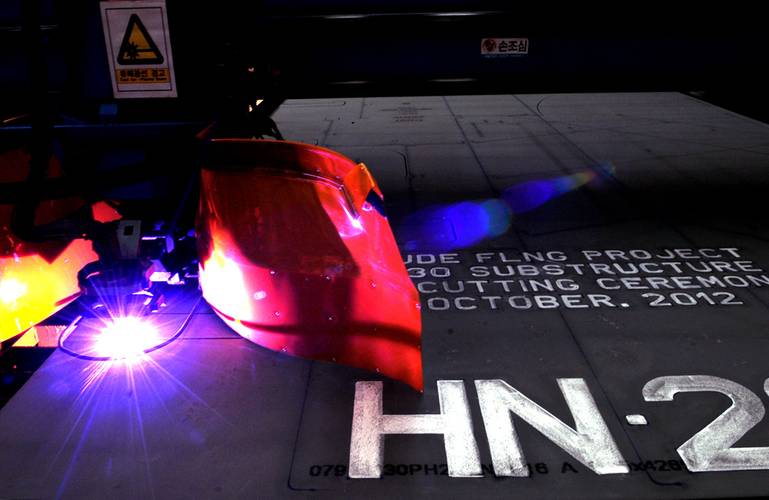

A new milestone was reached in the world’s use of LNG as fue, as Shell celebrated the cutting of first steel for the Prelude floating liquefied natural gas (FLNG) facility’s substructure with joint venture participants, Inpex and KOGAS, and lead contractor, the Technip Samsung Consortium, at Samsung Heavy Industries’ Geoje shipyard in South Korea.

“We are cutting 7.6 tons of steel for the Prelude floating liquefied natural gas facility today, but in total, more than 260,000 tons of steel will be fabricated and assembled for the facility,” said Shell’s Projects & Technology Director Matthias Bichsel . “That’s around five times the amount of steel used to build the Sydney Harbor Bridge.”

When completed, the Prelude FLNG facility will be 488 m long and 74 m wide, making it the largest offshore floating facility ever built. When fully equipped and with its cargo tanks full, it will weigh more than 600,000 tons. There will be over 3,000 km of electrical and instrumentation cables on the FLNG facility, the distance from Barcelona to Moscow.

“Making FLNG a reality is no simple feat,” Matthias said. “Shell is uniquely positioned to make it a success given our commercial capability; our LNG, offshore, deepwater and marine technology; and our proven ability to successfully deliver megaprojects.”

In order to meet the world’s growing energy demand, bringing new supplies to market is critical. The Prelude FLNG facility will be deployed in Australian waters over 200 km from the nearest point on the coast. It will produce gas at sea, turn it into liquefied natural gas and then transfer it directly to the ships that will transport it to customers.

A team from Shell will manage the multi-year construction of the FLNG facility to ensure the Prelude project’s critical dimensions of safety, quality, cost and schedule are delivered. Strategic partners Technip and Samsung Heavy Industries (the Technip Samsung Consortium) along with SBM and hundreds of suppliers and contractors around the world are all contributing valuable knowledge, skills and equipment to help make the project a success. At peak levels, around 5,000 people will be working on the construction of the FLNG facility in South Korea; and another 1,000 will build the turret mooring system, subsea and wells equipment in other locations across the globe.

n the lead up to the facility being ready to start production, a number of actions will take place, such as drilling the production wells, installation of subsea flowlines and risers and mooring chains to prepare for the arrival of the FLNG facility.

Prelude FLNG is the latest in a line of Shell achievements in developing new technologies for the oil and gas industry, reinforcing its leadership in technology and innovation. This is the first of what Shell expects to be multiple Shell FLNG projects.