A Shipyard First Bug-O System’s Heavy-Duty MDS and Hardcoat Anodized Rail

With popular television shows such as “Modern Marvels” and “How It’s Made” showcasing larger structures and assemblies being designed, built and often welded, it’s important that manufactures and builders be equipped to handle such construction landmarks. In the last twenty-five years, huge construction projects have gone underway and some have since been completed with more and new projects to start every day. Such projects as the Oakland-San Francisco Bay Bridge, Burj Khalifa in Dubai and Virginia Class Submarines were and are some projects driving the welding industry.

In all the cases stated above, the end result of these projects were often times setting a worlds record, such as a reliable route of travel or one of the world’s foremost wartime vessels. It’s important that the equipment joining segments together be able to handle all aspects of the construction and environment. Typically larger structures require more durable equipment that must be relied upon 24/7 to hit deadlines. Without these advancing pieces of equipment and technology to match the advancing world and what it has to produce, nothing would get accomplished without running over budget and missing project delivery deadlines.

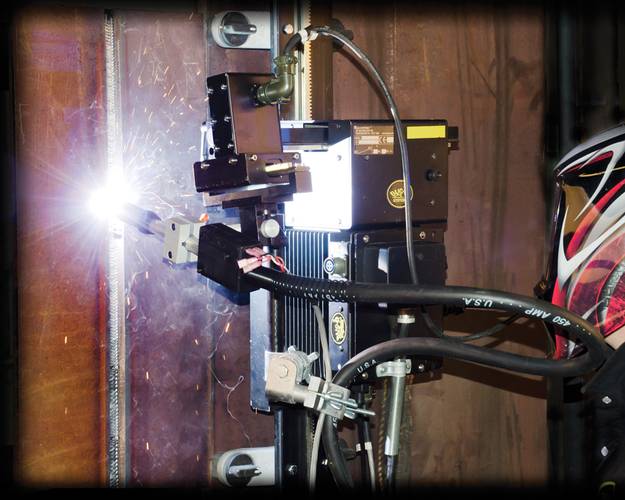

Recently, in an effort to keep pace with the growing demands of technology and the industry, BUG-O Systems has developed and released the new Heavy-Duty Modular Drive System for those who demand greater Mechanized Welding and need more carrying capacity and longer lasting rail sections for more harsh environments. In 2012, V.P. of Operations, Mark Binder and his Engineering R&D Staff released the H.D. MDS along with an industry first rail section which features a black hardcoat anodized surface and electroplated gear rack. At the request of many customers, this recent release was a few months in development as it was critical to offer the new Heavy Duty Package while still maintaining the modular design of the machine as well as the current size and user friendliness. Presently in use at Electric Boat, for use on welding hulls of the Virginia Class Submarines, the system has been in Field Beta Testing since the end of 2012, reflecting usage results that have surpassed that of originally calculated data in R&D labs. Spring 2013 was the first available release date for sale in the United States as well as all markets around the world.

New improvements in the machine including a larger, heavy duty drive motor as well as a H. D. fail-safe brake are behind the success of the new Master Drive unit. With these new additions, the drive has more than doubled its pulling power as well as doubled its braking power when turned off or in fail-safe mode due to loss of power. Traditionally, a Modular Drive comes rated with a vertical load capacity of 60 lbs. including the weight of the machine and carriage. With recent developments, the available vertical load capacity of an H.D. MDS has been tested and rated at 125 lbs. including tractor and carriage weight. With increasing the available vertical payload by 108%, engineering also increased the braking power by 100%, thus allowing the end-user or welder to carry more along with their tractor and essentially create an all-in-one welding unit that carries a wire feeder and wire spool.

The new H.D. Hard Coat Anodized Rail Concept was something to also consider along with the more robust unit as well. Since we’d be carrying more weight on the carriage, which rides directly on the rail, it would cause the standard Aluminum Rigid Rail to wear out at a faster than normal rate, causing the end user to potentially have to purchase higher than normal amounts of rail. Additionally harsh environments such as ship yards would realize even fast wear rates. Since the Rigid Rail is essentially the backbone of a welding operation with an MDS, every precaution had to be taken to ensure the rail would endure the constant use of two to three shifts a day while also operating at the heavier load. By hard coating the surface of the rail, an anodizing layer was added .001 below the surface into the material, as well as .001 over the aluminum, thus taking the material hardness from approximately 30 RC and increasing it to approximately 62 RC, or making it twice as wear resistant as before being introduced into the electro-chemical process. In addition to the hardcoat rail, adding an electro-plated zinc gear rack increases the longevity of the steel gear teeth which is in constant contact of the 4340 Chrome Molly pinion. In adding the additional coatings to the rail, aluminum hardcoating and electro-plated racking, the workable or useable life of a piece of rail can now be extended to two and a half times its normal expected life span before having to be replaced with another section. All this, coupled with the fact that Bug-O Systems offers the ONLY 3-year warranty in the industry, truly offers the customer piece of mind and greater overall reliability.

Generally, in the shipbuilding industry, it can be said that ships are in fact not getting smaller anytime soon and often require a great deal more attention when it comes to design and construction. Recently, in efforts to reduce the cost of a vessel they are being constructed of thinner material, which involves higher levels of engineering to address the once unimportant issues as relieving stresses, buckling and distortion caused by large amounts of heat input from welding. Using new machines, such as the H.D. MDS allows a user to control his heat input and almost eliminate distortion due to over-welding, not to mention reduce costs as the necessary sized welds can be met and repeated time after time. Having the ability to also carry higher payloads with your tractor, while extending its workable life, only compounds on the dollars and cents saved over the entire build time of a Virginia Class Submarine for one of many successful examples.

(As published in the September 2013 edition of Maritime Reporter & Engineering News - www.marinelink.com)