Offshore: Feedering for the Win(d)

With clean energy projects maturing in U.S. waters, the nation’s offshore wind industry is poised to grow substantially, requiring a robust industrial base. A feedering model using domestic tugs and barges to transport turbines to offshore wind sites, is positioned at the heart of this emerging growth.Currently, the entire global fleet of wind turbine installation vessels (WTIV)—except for Dominion Energy’s Charybdis currently under construction at the Seatrium AmFELS yard in Brownsville, Texas—is flagged, owned and operated outside of the U.S.

Seaqualize Executes Offshore Transfer Lifts on Vineyard Wind 1

Dutch heave compensation specialist Seaqualize executed the world’s first offshore transfer lifts of wind turbine components from a heaving supply vessel.The company’s newly developed offshore lifting device, the Heave Chief 1100, is being deployed by DEME Offshore US to instal the first turbines at Vineyard Wind together with the feeder barge solution developed by DEME Offshore US, with partners Barge Master, Foss Maritime and Seaqualize, and the operators and equipment from…

DEME Offshore, Barge Master Develop Feeder Solution for U.S. Offshore Wind Farms

Belgian offshore installation firm Deme Offshore and Dutch company Barge Master, which specializes in offshore motion compensation systems, have partnered up to further develop a U.S. Jones Act-compliant feeder solution for the upcoming offshore wind projects in the U.S.Last year, DEME Offshore was selected by wind farm developer Vineyard Vind to provide the offshore transport and installation of 62 GE Haliade offshore wind turbines for the Vineyard Wind 1 project, the first large-scale offshore wind installation in the United States.

Watch: Barge Master's Motion-compensated Solution for Offshore Wind Feeder Vessels

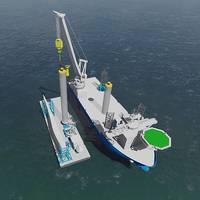

Dutch company Barge Master earlier this year said it had developed a motion-compensated feeder solution for the next generation of offshore wind turbines, called BM-Feeder.The company at the time said that its motion-compensated platform could be placed on an offshore vessel or barge and ensure that the components are kept completely stable for the hook-on and lift-off by the installation jack-up, and that, with its adjustable payload capacity was capable of "feedering" all turbine components, including future generations of wind turbine generators.Barge Master is apparently targeting the U.S.

Barge Master Develops Motion Compensated Feeder for Next-Gen Wind Turbines

Dutch company Barge Master has developed a motion-compensated feeder solution for the next generation of offshore wind turbines, called BM-Feeder.The company said that its motion-compensated platform with its adjustable payload capacity is capable of "feedering" all turbine components, including future generations of wind turbine generators."The BM-Feeder can be placed on an offshore vessel or barge and ensures that the components are kept completely stable for hook on and lift-off by the Installation Jack-Up. Motion-compensated feedering offers major benefits for the feeder operation.

Alaska Marine Lines Picks Up Sause's Hawaii Service and Barges

Alaska Marine Lines expanded its fleet with the purchase of two cargo barges, the Kamakani and Namakani, from Oregon-based Sause Bros. Sause terminated its Hawaii service in March and Alaska Marine Lines is now serving its customers.The Kamakani and the Namakani are now the largest of all Alaska Marine Lines vessels – each with a 438-foot overall length and 105 feet of width and a payload of 16,869 tons. "For comparison, our railbarges are 420 feet long and 100 feet wide with a payload of 15…

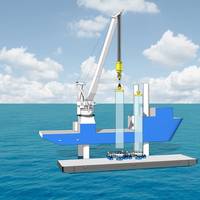

Approval in Principle for Steady Top Feeder Solution

London Offshore Consultants (LOC) has provided Barge Master and GustoMSC with an approval in principle for the work method of their Steady Top Feeder solution. This independent and impartial acceptance is an important next step in implementing this solution in US offshore wind projects.Barge Master and GustoMSC asked LOC to act as if they were appointed as the marine warranty surveyor of an offshore wind project and on that basis to assess whether the solution of the Steady Top Feeder is in principle acceptable to them.

Barge Master 3D Motion Compensated Crane for Wagenborg

Wagenborg awarded Barge Master a contract for a second 3D motion compensated crane for its new walk-to-work vessel Kasteelborg. The first motion compensated crane on the Kroonborg has increased the workability from approximately 180 to 330 days per year. “The crane works quite happily in three meter seas,” said Haije Stigter, former program manager at ONEgas/Shell, notes - adding that it “works like a dream.”The Barge Master Crane, as configured for the Kroonborg, makes it possible to continue safe and stable crane operations even in the North Sea’s famously rough conditions.

New Feeder Solution to Serve US Offshore Wind Market

Dutch companies GustoMSC and Barge Master join forces in the development of a motion-compensated feeder solution to service the emerging U.S. offshore wind marketsThis solution offers a flexible and cost-effective alternative for installing the first wave of U.S. projects. Combining the strengths of both companies creates a strong and advanced technical organization with commercial representative offices in the United States, through which prospective clients will be served.GustoMSC…

Vroon W2W Vessel Upgraded ahead of First Charter

VOS Start, Vroon BV’s first DP2, subsea-support, walk-to-work (W2W) vessel has departed Damen Shiprepair Oranjewerf following the installation of a first of its kind motion-compensated gangway system by Barge Master and Bosch Rexroth, the extended installation of a Kongsberg reference system (including a ‘windfarm module’), and an active heave-compensated crane from SMST. The 80m VOS Start arrived at Oranjewerf on June 1 from her build yard in China, staying for eight weeks in the yard to also undergo various other upgrades and preparations for her first project…

New Motion Compensated Gangway Unveiled

Barge Master and Bosch Rexroth have jointly introduced a new motion compensated gangway to the offshore wind market. After numerous simulations and virtual tests, the first actually manufactured gangway is currently being tested onshore at the Bosch Rexroth facilities in Boxtel, the Netherlands. On June 21 this location was transformed into a presentation area, where the visitors were informed about the partnership between the two companies, and allowed to have a close look at the complex technology on the demonstrated gangway.

VOS Start Equipped with Barge Master Gangway

Vroon has announced that walk-to-work vessel VOS Start is to be equipped with the brand-new Barge Master Gangway. This unique combination will enable safe and efficient transfer of personnel and cargo. The Barge Master Gangway incorporates an access tower with elevator, providing stepless access. The adjustable pedestal provides full flexibility in landing heights. With the participation of Bosch Rexroth in the Barge Master team, the highest quality and safety standards are guaranteed. This unrivalled, next-generation walk-to-work vessel will be available to the offshore industry in Q2 2017.

New Offshore Gangway Launched at ONS

The new Barge Master Gangway will be presented at the joint booth of Barge Master and Bosch Rexroth during the international offshore trade exhibition ONS (Offshore Northern Seas) in Stavanger. The next generation gangway, a result of cooperation between Bosch Rexroth and Barge Master, is designed for the safe and efficient transfer of personnel and cargo from ships to drilling and offshore production platforms, wind turbines and other ships. Barge Master specializes in the development and fabrication of motion compensating systems…

Barge Master Wins Innovation Award at OTC

The Barge Master T40 motion compensated knuckle boom crane has been recognized for technological innovation, winning the Spotlight on New Technology Small Business Award at this year’s Offshore Technology Conference (OTC) in Houston. Barge Master develops motion compensation systems for the maritime industry that compensate vessel motions, creating a platform that is not moving with respect to the stationary fixed world. The systems are developed to increase the safety and workability of offshore lifting operations.

Barge Master Launches Fit-for-Purpose Gangway

Press release - Barge Master has announced the official launch of a motion compensated gangway after building a track record in motion compensated lifting. ‘The overall offshore logistics consists of safe and efficient transfer of cargo and people. While we are already known for our motion compensated lifting, customers asked us to deliver the complete package: one supplier for both cargo and people transfer’, says Martijn Koppert, CEO of Barge Master. ‘Based on the input of a team of industry experts we designed the gangway…

Driving Innovation: the Unmanned FLNG

DNV GL developed a new unmanned floating LNG concept that it claims overcomes many of the challenges faced by operators looking to unlock the potential of remote offshore gas fields. Called Solitude, DNV GL said the concept demonstrates how technological advances can be combined into a solution that offers an estimated 20% reduction in annual OPEX, only adding a few percent increase in CAPEX and at the same time increasing overall safety. Foreseeing the need for more remote projects to be able to overcome even more challenging cost barriers…

Barge Master Aids Shell Project in the Philippines

Barge Master informs it used its BM-T700 motion compensation platform to support the installation of the permanent connection bridge (151mT, 42.5x3.5x3.5m) between a newly installed depletion compression platform (DCP) and an existing gas producing shallow water platform (SWP)for the Shell Malampaya production platform in the Philippines. The project was executed by Boskalis for Shell Philippines Exploration B.V. and comprises the installation of an offshore depletion compression platform at the Malampaya gas field, in the Republic of the Philippines.

Motion Compensation Crane Delivered

Barge Master has delivered its first Barge Master T40 (BM-T40) motion compensated knuckle boom crane, the company announced. The BM-T40, installed on Wagenborg’s ‘Walk to Work’ vessel the Kroonborg, compensates for sea induced vessel motions in roll, pitch and heave directions at the base of the crane, up to three meters significant wave height. The BM-T40 is designed for offshore support vessels that are used to transfer small loads and personnel to (unmanned) offshore oil and gas platforms or wind turbines.

New Floating Installation Concept for Offshore Wind

Conquest Offshore, together with deugro Denmark A/S, has developed an installation system for monopiles and transition pieces, supported by Temporary Works Design (TWD) and Barge Master. Aiming to produce a solution for optimizing the installation process within the offshore wind industry, the parties have combined their experience and knowledge of floating installation, offshore skidding, upending, pile handling and motion compensated tools and to develop the new floating installation concept. The newly designed skidding system makes a full deck load on the 136 meter barge possible. The ability to upend monopiles (from deck and floating) and the use of a specially designed motion compensated pile gripper provide the means for floating installation.

Barge Master Receives ISO 9001 Certification

Barge Master has obtained ISO 9001 certification for the development and exploitation of its offshore motion compensation systems, the company announced today in a press statement. Barge Master said its quality assurance, safety, health and environment (QASHE) system is in compliance with legal, industry and Barge Master standards. For the quality part, the company received the ISO 9001 certificate. According to Barge Master, the company is able to work more efficiently by standardizing its processes. The company expects its personnel to use the standards and train new staff to use them, too.

Barge Master Installed on Walk-To-Work Vessel

On October 14 the Barge Master BM-T40 system motion-compensated knuckle boom crane pedestal was installed on the new Wagenborg Walk-to-Work vessel, designed and built by Royal Niestern Sander. The vessel and Barge Master system will be delivered in the first quarter of 2015. NAM will use the motion compensated crane for service and maintenance of gas production platforms in the Southern North Sea. Offshore platforms have become smaller and more flexible during the last forty years.

Barge Master T700 to Be Installed on Boskalis Ndeavor

A Barge Master BM-T700 system was unloaded in Singapore today as it awaits the early 2015 arrival of DP-2 multipurpose vessel Boskalis Ndeavor. According to Barge Master, the T700 will be mobilized on the Ndeavor and continue to the Phillipines where a bridge will be installed between two gas platforms using the Barge Master to compensate the motions of the bridge as a result of the waves. Built by Samsung C&T corporation ZPMC - Shanghai Zhenhua Heavy Industries Co.Ltd in 2013…

Storm Causes Deadly Grounding in the Philippines

A storm off the Philippines caused a ship grounding incident in Antique yesterday morning which claimed one casualty, local authorities reported. The 18 other seafarers involved in the incident are reported safe. The Philippines Coast Guard’s investigation revealed that M/Tug Benny and its towing barge Brian took shelter at the vicinity waters of Barangay Balud, Tobias, Antique as Tropical Depression Seniang battered the Visayas region. Both vessels drifted toward the shoreline due to strong winds and waves. Twelve crew members from Barge Brian were able to swim towards the shoreline while the remaining seven crew of M/Tug Benny transferred to the barge waiting for rescue, the coast guard said. Upon receiving a VHF call from barge master Dillio S.