Bosch Rexroth Appoints North and Central America CEO

Bosch Rexroth has appointed Erwin Wieckowski, P.Eng. as the new President and CEO of Bosch Rexroth North and Central America based in Charlotte, NC, effective October 1, 2023.The role has been performed on an interim basis by Reinhard Schaefer in addition to his role as a member of the Divisional Board of Management with responsibility for Manufacturing. Schaefer will remain in the region to support the transition.“We are thrilled to have Erwin join our organization,” said Schaefer.

Tech Files: Offshore Safety Systems & Equipment

Safety of workers,structures, equipment and the environment are paramount in any offshore energy project. In the March/April print edition, Offshore Engineer took a look inside some notable newcomers.Wearable tech to boost drill floor safetyHaloGuard – Credit: TransoceanOffshore drilling contractor Transocean has recently deployed what it said was the offshore drilling industry’s first safety system that integrates a wearable locating device with drill floor equipment and machine stoppage controls.The system…

Offshore Equipment Hydraulic Maintenance Tip-of-the-Day: Tribology

Tip #1: Tribology - Assume All Hydraulic Components are Designed EquallyBelieve it or not, maintenance begins during the design phase. Moving parts create friction, and friction can lead to wear, ending in premature failure, especially when tribology is ignored. In order to have a long-lasting hydraulic system, it is critical to specify operating conditions and environment during the project start. When all conditions are considered, it is possible to select the right component…

Gumbs to take the Helm of Bosch Rexroth North America

Paul Cooke, President and CEO of Bosch Rexroth North America, based in Charlotte, NC, USA, will retire on December 31, 2020 after 38 years of service in various international positions within Bosch Rexroth. His successor as of December 1, 2020 will be Greg Gumbs, most recently Vice President & General Manager Electrical Automation Solutions at EATON Corporation. Gumbs will join Bosch Rexroth effective September 1, 2020 in preparation for his future responsibility and will be based at Bosch Rexroth North American headquarters in Charlotte…

Navigating the Rough Waters of Marine Certification

The marine industry brings its own unique set of challenges.With the ‘All Subsea Factory’ market trend moving offshore exploration and production equipment for oil and gas to the seabed, safety, longevity and environmental protection are just a few of the considerations when choosing marine products. When selecting products for marine applications, the understanding of factors such as marine certifications and inspection documents are crucial to making an informed decision.Worldwide statutory provisions enacted by the United Nations (UN) agency on shipping specify general regulation and rules necessary to obtain an operating license for all categories of ship, marine and offshore applications.

Bosch Rexroth Bags Fugro Contract

Fugro, the global geo-data specialist, has awarded a contract to Bosch Rexroth to fully maintain and further improve Fugro Synergy’s hydraulic equipment.Fugro has worked with Bosch Rexroth for over a decade to ensure it has the best hydraulic systems and software solutions on board its geotechnical drilling vessel, the Fugro Synergy. Now, they are working together again in order to better prepare for the future.The Fugro Synergy vessel has been in operation since 2009, and is primarily used to drill into the seabed in order to analyse whether it can be safely used as a foundation for structures like wind farms or oil rigs. This ship was built to be effective in the harshest conditions…

Efficient Wave-Generated Power … Really!

Wave-generated power could be considered the Rodney Dangerfield of offshore renewable energy sources; it gets no respect. There have been a number of high-profile, expensive failures that have conspired to give the sector a poor reputation despite a number of engineering advances. A new entrant is SurfWEC offering a patented “surf-making” Wave Energy Converter which has been in development since 2007. Its developers promise it will stand out from the field and perform where others have failed. How?

Rexroth’s GoTo Focused Delivery Program Continues Growth

Bosch Rexroth said its GoTo Focused Delivery Program has marked its 9th consecutive year of growth by offering a strong product portfolio of thousands of Rexroth products with best-in-class lead times.The program continues to offer high demand products across Rexroth’s broad range of technologies for fast delivery. Considering product-dependent maximum order quantities, customers benefit from short lead times and unrivaled simplicity. More than 99 percent of the products in the program ship in 10 days or fewer, with the same lead times in the U.S., Canada and Mexico.

Barge Master 3D Motion Compensated Crane for Wagenborg

Wagenborg awarded Barge Master a contract for a second 3D motion compensated crane for its new walk-to-work vessel Kasteelborg. The first motion compensated crane on the Kroonborg has increased the workability from approximately 180 to 330 days per year. “The crane works quite happily in three meter seas,” said Haije Stigter, former program manager at ONEgas/Shell, notes - adding that it “works like a dream.”The Barge Master Crane, as configured for the Kroonborg, makes it possible to continue safe and stable crane operations even in the North Sea’s famously rough conditions.

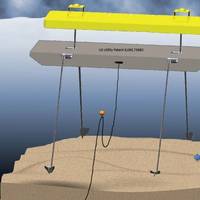

New Offshore Decommissioning Barge

Longitude Engineering reportedly has developed a cost effective decommissioning barge concept for the removal of small oil and gas platforms for the PTT Exploration and Production (PTTEP), a subsidiary of the Thai state owned oil company. The aim was to develop a viable and cost-effective alternative to conventional ‘reverse installation’ through the use of heavy lift crane barges for the removal of the topsides and jackets. The focus being the removal of 90-100 of PTTEP’s minimum facilities platform assets in the Gulf of Thailand…

Bosch Rexroth Celebrates 50 Years in the US

2017 marks Bosch Rexroth’s 50th year of continuous operation in the United States. Starting with a small office in Easton, Pa. in 1967 and a handful of associates, Rexroth grew to expand into a newly built hydraulics manufacturing facility seven years later, the cornerstone of the company’s current manufacturing campus in Bethlehem, Pa. As Rexroth expanded globally, so did the company’s operations in the U.S., eventually identifying itself as “The Drive & Control Company.” Under this claim…

Vroon W2W Vessel Upgraded ahead of First Charter

VOS Start, Vroon BV’s first DP2, subsea-support, walk-to-work (W2W) vessel has departed Damen Shiprepair Oranjewerf following the installation of a first of its kind motion-compensated gangway system by Barge Master and Bosch Rexroth, the extended installation of a Kongsberg reference system (including a ‘windfarm module’), and an active heave-compensated crane from SMST. The 80m VOS Start arrived at Oranjewerf on June 1 from her build yard in China, staying for eight weeks in the yard to also undergo various other upgrades and preparations for her first project…

New Motion Compensated Gangway Unveiled

Barge Master and Bosch Rexroth have jointly introduced a new motion compensated gangway to the offshore wind market. After numerous simulations and virtual tests, the first actually manufactured gangway is currently being tested onshore at the Bosch Rexroth facilities in Boxtel, the Netherlands. On June 21 this location was transformed into a presentation area, where the visitors were informed about the partnership between the two companies, and allowed to have a close look at the complex technology on the demonstrated gangway.

Intelligent Self-sufficient Systems for Powerful Drive Tasks

New from Bosch Rexroth are standalone axes with identical servo-drives for actuators with mechanical or hydraulic force transmission, offering new degrees of freedom for machine manufacturers in finding drive solutions that suit specific application requirements. The versions with hydraulic transmission are provided with their own, decentralized fluid circuit. The installation, commissioning and connection to controls and Industry 4.0 environments via a Multi-Ethernet interface or ProfiBus are identical on both variants.

PANOLIN HLP SYNTH 32 Obtains RDE 90235

PANOLIN HLP SYNTH 32 is the first and so far only eco-friendly hydraulic oil to feature in the Bosch Rexroth RDE 90245 Fluid Rating List. “Yet again, we have proven that our biodegradable products such as PANOLIN HLP SYNTH 32 also meet the highest industry requirements,” said Patrick Lämmle, Chairman of the Board of Directors of PANOLIN International. “PANOLIN HLP SYNTH is the first rapidly biodegradable hydraulic oil to obtain the Fluid Rating (ISO 15380 in combination with RFT-APU-CL test),” Lämmle said.

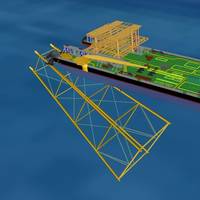

Pioneering Spirit: Addressing Drive & Control Challenges

It was the biggest assignment Bosch Rexroth in Boxtel had ever faced, and it took more than two years to carry it out. But they seized with both hands the opportunity to research and supply the hydraulic components and associated local controls for the innovative lifting system on board the Pioneering Spirit, conceived and developed by Allseas. The request came from Allseas, an offshore specialist, or in fact from founder and owner Edward Heerema. A specially designed ship to lift entire offshore platforms off their piles in a single movement…

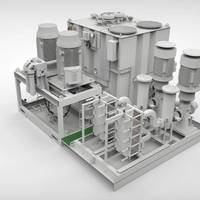

Bosch Rexroth Introduces Modular Hydraulic Power Units

Bosch Rexroth is launching a modular hydraulic power unit (HPU) program specially developed for the maritime and offshore market. These power units cover a power range of 350 to 3,000 kW, and have obtained the type approval by Lloyd’s Register. The program starts with a "basic" unit which can be expanded using all kinds of options. Because all variants are included in the modular options matrix, a design can quickly be calculated complete with dimensions and weights. Pierre Wouters…

VOS Start Equipped with Barge Master Gangway

Vroon has announced that walk-to-work vessel VOS Start is to be equipped with the brand-new Barge Master Gangway. This unique combination will enable safe and efficient transfer of personnel and cargo. The Barge Master Gangway incorporates an access tower with elevator, providing stepless access. The adjustable pedestal provides full flexibility in landing heights. With the participation of Bosch Rexroth in the Barge Master team, the highest quality and safety standards are guaranteed. This unrivalled, next-generation walk-to-work vessel will be available to the offshore industry in Q2 2017.

New Offshore Gangway Launched at ONS

The new Barge Master Gangway will be presented at the joint booth of Barge Master and Bosch Rexroth during the international offshore trade exhibition ONS (Offshore Northern Seas) in Stavanger. The next generation gangway, a result of cooperation between Bosch Rexroth and Barge Master, is designed for the safe and efficient transfer of personnel and cargo from ships to drilling and offshore production platforms, wind turbines and other ships. Barge Master specializes in the development and fabrication of motion compensating systems…

ZF Acquires Bosch Rexroth Industrial Gears Arm

Following the go-ahead from antitrust authorities, on December 1, 2015 ZF has officially taken over the industrial gears and wind turbine gearbox business from Bosch Rexroth AG. With this, some 1,200 employees altogether at the Witten, Beijing and Lake Zurich (USA) locations will thus join the technology company. The purchase price has not been disclosed. For ZF, the acquisition is an entry into the business with large industrial gears that are used in oil rigs, mine vehicles, tunnel drilling machines, or cableways, for instance.

Motion Compensation Crane Delivered

Barge Master has delivered its first Barge Master T40 (BM-T40) motion compensated knuckle boom crane, the company announced. The BM-T40, installed on Wagenborg’s ‘Walk to Work’ vessel the Kroonborg, compensates for sea induced vessel motions in roll, pitch and heave directions at the base of the crane, up to three meters significant wave height. The BM-T40 is designed for offshore support vessels that are used to transfer small loads and personnel to (unmanned) offshore oil and gas platforms or wind turbines.

Damen Delivers Custom-Made Offshore Winches to Fugro

Damen Maaskant Shipyards, part of Damen Shipyards Group, has delivered two dedicated offshore winches to Fugro. The Dutch shipyard was responsible for the design, engineering and manufacturing of the two winches from its base in Stellendam in the Netherlands. Maaskant also worked very closely with Bosch Rexroth, which delivered the hydraulic drive system. Classified by DNV GL, the two winches – a constant tension winch with an own weight of 2,000 kg and a drilling winch (own weight 3,500 kg) - have to meet the very highest offshore standards.

Upgraded Winch Control from Rexroth

Bosch Rexroth has upgraded the electrohydraulic controller used on the company’s A4VSO and A4VSG hydraulic axial piston components, which function as secondary control units in the Rexroth Active Heave Compensation (AHC) system for offshore winching applications. Replacing the previous DS1 model, the new Rexroth DS2R electrohydraulic controller features proportional valve technology for more reliability, easier maintenance and lower cost, the manufacturer said. The controller…