NYK Line’s 3D Design for Multi-Purpose Container Carrier Gets ClassNK Pass

ClassNK has granted approval to the basic design drawings of a multi-purpose container carrier developed by Nippon Yusen Kabushiki Kaisha (NYK Line) utilizing 3D models.This marks the world's first ocean-going ship to complete the basic design process, including class approval, solely through 3D drawings from the conceptual design to the basic structural design, during the initial stages of ship construction, according to NYK Line and ClassNK.Traditionally, the sharing of design information among shipyards…

ABS, SHI Sign Digital Technology JDP

ABS and Samsung Heavy Industries (SHI) are to collaborate on the use of digital technologies to streamline designing, building, and classing assets in a joint development project (JDP) signed at Gastech 2019.The JDP encompasses 3D digital disclosure, data exchange, and the use of analytics to support the new construction process and pilot the survey of the future.The JDP is focused on three areas:•Piloting 3D Model Based Plan review•Developing a utility to import data from the…

Mobile Analysis: 3D, 2D CAD Viewer "to go"

The CoreTechnologie 3D Analyzer Viewer is now available through a mobile license-lending feature.The powerful 3D Analyzer Viewer of the German-French software manufacturer CoreTechnologie (CT) comprises in the current version 4.3 anew license-borrowing function that allows to use the software for a limited time for example on a laptop. Already the inexpensive basic version of 3D Analyzer includes 24 different interface formats, such as CATIA V5/V6, NX, Inventor SolidWorks, Creo, STEP, JT as well as FBX and OBJ.

Shipbuilding: $13.3 Mln Awarded for R&D Projects

The National Shipbuilding Research Program’s (NSRP) Executive Control Board has selected a new round of research and development (R&D) projects aiming to spur technology advancements in order to reduce costs associated with shipbuilding and ship repair in the U.S. The seven projects – valued at over $13.3 million, including cost share – were selected from those proposed in response to research announcement issued in July 2017, and are outlined below. Objective: The primary goal…

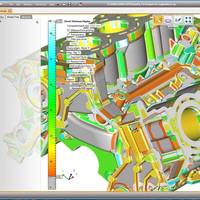

Managing Change the AVEVA Way

In today’s marine-scape of declining newbuild activity, many boatbuilders are seeking to buoy up productivity by reducing time to market. But how do you go about contracting intricate concurrent design and production flows without loss of quality, let alone the risk of production spiraling out of control? The general tendency is to overlap design phases. However, this potentially creates a greater number of uncertainties. Ship design includes multiple disciplines and specialties in spiraling activity cycles.

Product Lifecycle Management for Shipbuilding

Tomorrow’s high tech fleets will depend on shipyards – long after the christening is over. Siemens PLM software makes that dream possible – today. According to global powerhouse Siemens, a major transformation is underway in the marine sector. As operators strive to develop more energy-efficient, reliable and environmentally friendly vessels that also lower operating costs, they will increasingly depend on shipyards to make that happen. That’s right: shipyards. Long after the vessel slides into the water and the christening party is but a distant memory, the clean and efficient workboat of tomorrow will leverage a wealth of data that the builder will manage. Before any of that happens, shipbuilders will also need to design and build ships faster and better than ever before.

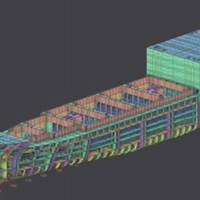

ShipConstructor Drives Automatic Welding Robots

The last barrier to robotic shipbuilding has just fallen. What comes next will be truly exciting. It wasn’t too long ago that SSI and Wolf Robotics demonstrated some co-development which automatically drove a fully autonomous welding robot to weld several ship panels. SSI develops Autodesk based solutions for the shipbuilding and offshore industry including ShipConstructor software, an AutoCAD based CAD/CAM product line; and EnterprisePlatform, a tool for sharing product data model information. For its part, Wolf Robotics has been integrating robotic welding and cutting systems since 1978. The collaboration was part of a National Shipbuilding Research Program (NSRP) Computer Aided Robotics Welding (CAR-W) project with U.S. shipyards.

FORAN System of Designing, Building Twin Vessels Presented at SNAME

The engineering and technology group SENER has once again participated in “SMC 2016”, the annual maritime convention organized by the Society of Naval Architects and Marine Engineers (SNAME) that brings together the main players in the US marine industry. This time the conference was held in Bellevue, Washington, on November 1-4. At the convention, SENER’s FORAN Area Manager for the United States and Canada, Verónica Alonso de los Ríos, presented the solution offered by the FORAN system for designing and building twin vessels, with a paper she wrote together with the Head of Naval Business Development, Rodrigo Pérez Fernández. As a shipbuilding CAD/CAM system that has been on the market for over 50 years…

SENER Presents Study on Implementation of CAD System

At the annual COMPIT conference, the SENER engineering and technology group presented a technical/economic study on the implementation of a CAD system in a shipyard and, in particular, the FORAN System, developed by SENER. The event took place in Lecce, Italy, on May 9, 10 and 11. COMPIT is an international conference focusing on software applications and information technologies that have been well received within the marine sector. The event is always held in Europe. Rodrigo Pérez, from SENER’s Marine Department, presented the article ‘Learning Curve and ROI in the Implementation of a CAD System in a Generic Shipbuilding Environment’. The article provides an analysis of the FORAN system learning curve in a generic shipyard.

SENER Celebrates 50 Years of FORAN

The SENER Group division in Shanghai held a 50th anniversary celebration of FORAN system where it also presented its new version V80. More than 100 attendees from 40 companies including shipyards, design offices, classification societies, universities and partners attended the event. The event received endorsement from Embassy of Spain and CDTI (Spain’s Centre for the Development of Industrial Technology) with participation of representatives. The Economic and Commercial Consul from Economic and Commercial office in Shanghai of Embassy of Spain…

SENER Presents on History of Ship Design

The COMPIT annual edition took part this year from May 11-13 in Ulrichshusen, Germany, with the participation of SENER. This event is an International Conference on Computer Applications and Information Technology in the Maritime Industries that takes place every year in Europe. As in the previous edition Rodrigo Pérez presented a paper, which this year was about “History and Evolution of Shipbuilding Oriented CAD Tools” written by Rodrigo Perez and Carlos Gonzalez, both from SENER.

SENER Celebrates FORAN System’s 50th Anniversary

SENER has commemorated the 50th anniversary of FORAN, its CAD/CAM/CAE system for designing naval vessels and marine structures, created by SENER’s cofounder José Manuel de Sendagorta in the 1960s. Today it is the world leader in marine technology and, since its inception, it has served as the prime example of SENER’s ability to innovate and export. The event was held at Madrid’s Casino on the evening of Thursday, June 11, under the auspices of SENER’s founder and Honorary President…

Keel Laid in S. Korea for 1,200-passenger Vessel

The keel of the 1,200 passenger vessel designed by the engineering and technology group SENER was recently laid in the Factory No. 2 of POSCO PLANTEC, in Ulsan, South Korea. SENER said its representatives attended to the keel laying ceremony, which was presided by members of the Zanzibar’s Government, the owner of the vessel. The ship will operate in Northern Mozambique, Dar es Salaam, Zanzibar, Tanga and Mombasa. On behalf of the owner assisted to the ceremony the Principal Secretary of the Ministry of Infrastructure and Communications, Dr. Juma Malik Akil; the Principal Secretary of the Ministry of Finance, Khamis Mussa Omar; the Principal Secretary of the Second Vice President Office, Dr.

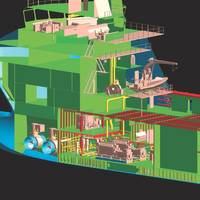

Sener Signs a Contract With Posco Plantec

The contract for the design of a 1,200 passenger vessel was signed between Sener and Posco Plantec (part of the South Korean group POSCO Family) in Madrid on June 13, 2013. The vessel is to be build and designed for the following operational areas: Northern Mozambique, Dar es Salaam, Zanzibar, Tanga and Mombasa. The scope of the project to be developed by Sener includes conceptual and classification engineering and the 3D model to extract the production information, and is going to be developed with the 3D CAD system Foran, developed by Sener.

SENER Presents Design Paper at SNAME Meeting

SENER has attended the 2013 SNAME (Society of Naval Architects and Marine Engineers) annual meeting from November 6-8 in Bellevue, Washington. During the event, technical sessions took place as part of the Ship Production Symposium, where engineers from the shipbuilding industry presented important innovations and advances in the state of the art for shipbuilding. Verónica Alonso, North America Area Manager from SENER Marine Business Unit, presented the paper: The use of a 3D CAD System at early design in shipbuilding, written with Antonio Valderrama and Rodrigo Pérez, all from SENER.

Tube Benders Speed Subsea Wellhead Construciton

All-electric tube bending machines from Unison are helping FMC Technologies - the leading supplier of subsea tree hydraulic control systems for wellheads - to substantially reduce build times and multiply its manufacturing capacity. Six sites worldwide now use Unison tube bending machines in a new production method pioneered by FMC Technologies employees in Norway and Scotland. The subsea systems supplier used to plan the routes for the hydraulic tubing runs that interconnect the valves and other component parts of the subsea trees…

New FORAN Academic License Agreements in Japan

Concluded FORAN Academic License Agreement with Hiroshima University. SENER concluded FORAN Academic License Agreement with Hiroshima University on February 15, 2013. Hiroshima University is the first licensee who introduced FORAN Academic License in Japan. It is very honorable to welcome Hiroshima University as a new FORAN user. Associate Professor, Ph.D. Akihiro Takezawa, Division of Mechanical System and Applied Mechanics, Faculty of Engineering of Hiroshima University, and Alfonso Cebollero, SENER Regional Director for Asia & Pacific, signed the Agreement at Okayama, where a FORAN seminar was taking place. Mr. Takezawa is an extensively active researcher and expert in the field of structural and vibration analysis, not only in the shipbuilding area.

Siemens Subsea Products Adopts All-Electric Tube Bending

Siemens Subsea Products has chosen an all-electric tube bender from Unison to improve the quality and speed the production of the small-bore hydraulic tubes it uses on subsea hydraulic flying leads with Multiple Quick Connections (MQC), Cobra Heads and associated offshore oil and gas recovery equipment. The tubes feature complex bends of extremely high accuracy, and until now the company has either fabricated them manually or bought them in as pre-formed sub-assemblies. Siemens Subsea Products produces a wide range of subsea electric…

Feeding the ERP Beast: Properly Integrating CAD and ERP

ERP systems are beasts. To be happy, they have to be well fed. Computer Aided Design/Drafting (CAD) systems are a source of the food for Enterprise Resource Planning (ERP) systems since they contain significant information regarding the plans and materials needed to construct a ship. ERP systems are data hungry. They can only be effective at planning purchasing and production as long as the beast is consuming the information that the CAD system provides. In fact, there is a direct link between the success of an ERP system and how well it is fed the information it requires to do its job.

Technology Updates: A 3D Virtual Interface to Access Ship Data

By Stephen J. Baum and Ted L. Individuals across the shipbuilding enterprise depend on Web access and availability of digital ship data to perform their daily duties. As increasingly larger quantities of ship data become available digitally, the end user often finds it difficult to locate the required data for several reasons. First, it is difficult for the causal user to quickly and easily navigate through volumes of data to find what is of importance. Simple keyword searches based on textual queries are often frustrating and are regularly unsuccessful due to the lack of data standardization. Second, data tends to be distributed across…

MAN B&W Expands Turbocharger Range

Following the introduction of the TCA axial turbocharger two years ago, MAN B&W Diesel Group announced an expansion of the range to include a completely new radial turbocharger. The TCR turbocharger will replace the current NR series that has been in production for nearly 50 years culminating in the current NR/S design. The new TCR series has a compressor pressure ratio of 4.7 and is capable of up to 5.2 when built as a special version. Aimed specifically at the medium and high-speed diesel and gas markets…

Dassault Systemes and IBM Partner With IHI

Ishikawajima-Harima Heavy Industries Co. Ltd (IHI) has signed an agreement with Dassault Systemes and IBM Product Lifecycle Management around 3D PLM (Product Lifecycle Management) for shipbuilding. 3D PLM solutions based on V5 architecture developed by Dassault Systemes and marketed by IBM world wide, are setting future industry standards which help shipbuilding companies reduce the development time as well as further improve their products. As part of the partnership, IBM and Dassault Systemes will integrate their 3D PLM technologies with IHI's specific industry know-how in order to promote the modernization of shipbuilding, one of the core industries in Asia. Services and support will be provided by IBM and IBM's business partners.

NSRP Shipbuilding Project a Success

The National Shipbuilding Research Program (NSRP) has successfully demonstrated a prototype computer architecture for enterprise-wide interoperability that facilitates the sharing of ship design data between different computer systems and platforms being used by shipyards and suppliers. The April 4, 2002, demonstration held at Electric Boat in Groton, Conn., meets a milestone of NSRP's Integrated Shipbuilding Environment (ISE) project, a three-year effort to develop and deploy an industry-wide architecture for computer interoperability. ISE is targeting cost and cycle time reduction for both Navy and commercial customers by providing real-time digital connectivity between shipbuilders and their suppliers.