Beating the Heat: R.W. Fernstrum & Company Turns 75

R.W. Fernstrum & Company, founded by Robert W. Fernstrum 75 years ago, is a quintessential U.S. manufacturing story. The company was born in the aftermath of WWII, founded on an invention developed during the war by Robert Fernstrum to help solve an engine overheating problem that was plaguing U.S. Navy landing craft. Family owned and operated from day one, today the company includes a fourth generation of family that aims to continue the legacy of its founder, a legacy built on effective…

Tech File: Engineered Cooling Solutions Help Improve Environmental Footprint

As owners and operators work to achieve dramatic new emission reductions, vessels’ cooling solutions should not be overlooked.A wave of green initiatives is sweeping through the maritime market as owners and operators seek ways to reduce emissions from their vessels. One company supporting this drive is R.W. Fernstrum, a global leader in engineering and manufacturing keel cooling technologies.Sean Fernstrum, the company’s president, sees a mix of power and propulsion solutions—each with its own list of pros and cons—combining to help reduce the industry’s environmental footprint. And R.W.

INSIGHTS: Sean Fernstrum, President, R.W. Fernstrum

This month, listen in as Sean Fernstrum weighs in on how his firm arrived at its enviable market position, what comes next, and why.Sean Fernstrum is a third-generation owner of R.W Fernstrum & Company. He graduated from Michigan Technological University in 1990 with a Bachelor of Science degree in Scientific and Technical Communications. After college, he came home to Menominee, Michigan and began working as a Technical Writer at R.W. Fernstrum & Company. He has been President of the company for the last 8 years.

MN100: R.W. Fernstrum & Company

The 2019 version of the MarineNews MN100 edition - our annual look at the very best individuals and firms in the shallow draft, brown water and workboat sectors - has come and gone. Anchoring that prestigious list, as always, is R.W. Fernstrum & Company. That's no surprise to MarineNews readers.THE COMPANY:R.W. Fernstrum & Company set the standard in marine heat exchangers over 70 years ago, building a reputation focused on innovation. Today, its commitment is to continual improvement, ensuring customers have quality, reliability, and the latest in cooling technologies.

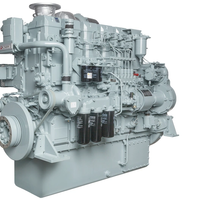

Mitsubishi: JMP for Keel Cooler Pump

Whether it's a pushboat, longliner, ferry or box ship, maintaining an optimal temperature is essential to an engine's performance and longevity. A keel cooler pump is no place to cut corners. That's why Mitsubishi Turbocharger and Engine America, Inc. chose the reliability of JMP Corporation's JPR-ME5000 for seven of its heavy and continuous duty engines, and cites the company's ongoing support as the reason it continues to do so.At 158 gph at 2,850 rpm, the JMP Corporation JPR-ME5000 Bronze Impeller Cooling Pump is a real performer. It has 2" NPT in and 1.5" NPT out ports.

R.W. Fernstrum Achieves ISO 9001:2015 Certification

R.W. Fernstrum & Company, a leading manufacturer in marine heat exchangers, received ISO 9001:2015 certification following an audit performed by Verisys Registrars in May. The scope of Fernstrum's registration includes the engineering, design, manufacturing, and sales of heat exchangers for marine and industrial applications. Published by the International Organization for Standardization, ISO 9001:2015 is an internationally recognized quality management system based on a set…

Boatbuilding 101: Keep It Simple

In an era of increasingly complicated regulations and sophisticated technologies disrupting the workboat sector, one piece of the equipment – the Keel Cooler – remains as possibly the most important and at the same time, the simplest piece of hardware on the water. Likewise, much the same way as it was more than 70 years ago, Fernstrum remains the standard. For today’s workboat sector, the most pressing issue facing operators is arguably comprised of meeting and paying for the advent of so-called ‘Tier’ emissions standards. The American subset of 5,500 towboats additionally faces the subchapter M towboat rules and new requirements for hardware installation and physical construction. The one thing they shouldn’t have to worry about is engine cooling solutions.

Insights: Pat Folan, Tug & Barge Solutions

Pat Folan, a partner at Tug & Barge Solutions, weighs in on all things tugboat – with a focus on Subchapter M. Pat Folan is a partner in Daphne, Ala.-based Tug & Barge Solutions, a company that focuses on Subchapter M compliance for towing companies. The company also performs surveys of towing vessels and barges, manages safety management systems for towing companies and trains people on towing vessels and in offices. A professional mariner, he has operated towing vessels from Maine to Corpus Christi, Texas, including the Alabama Rivers, Lower Mississippi, Great Lakes and Erie Canal.

Geo Gradel Tug and Barge Enter Drydock

Great Lakes Shipyard said it was awarded a contract for drydocking and repairs by Geo Gradel & Co. for tug George Gradel and barge Moby Dick. The contract for the 2,400 HP tug George Gradel includes steel repairs, keel cooler repairs, underwater hull inspections and repairs as well as painting and replacing fuel tanks. Work is planned to be completed by the end of June 2017. Worked completed for the 120' x 33' x 10.5' deck barge with 875-ton capacity included surveys, inspections and repairs for load line renewal. Work was completed on June 5, 2017.

R.W. Fernstrum: Keeping Things Cool for 67 Years

Founded by Robert W. Fernstrum 67 years ago, R.W. Fernstrum & Company is currently run by its third generation of Fernstrum. This long-tenured maritime staple has seen its fair share of maritime cycles, and in today’s challenging market it is not standing still. The company is digging for, and finding, business in all four corners of the world, above water and below, as Sean Fernstrum, President & owner, and his team explain. “Diversify, diversify, diversify … always,” is the…

MN100: R.W. Fernstrum & Company

R.W. Fernstrum & Company set the standard in marine heat exchangers over 65 years ago, building a reputation focused on innovation. Today, its commitment is to continual improvement, ensuring that customers have quality, reliability, and the latest in cooling technologies on your side. Over the years, R.W. Fernstrum & Company has grown into a worldwide organization with more than two dozen representatives across 6 continents. Focusing exclusively on marine cooling, this third-generation…

MN100: Dometic

Dometic develops products that make life on the water more comfortable and productive. An engineering leader of innovative products for the global marine industry with the largest worldwide sales and service network, products include air conditioning, ventilation, air purification, water purification, and sanitation. Compact, modular, and shell-and-tube chillers are customized for up to 2.4 million BTUs of climate control. The firm has about 300 employees. For a 72’ Signet tug boat…

R.W. Fernstrum: Keeping it Cool

Founded by Robert W. Fernstrum 65 years ago, R.W. Fernstrum & Company is now run by the third generation of Fernstrums who continue to build and extend its commercial marine heat exchanger business. Sean Fernstrum, President & Owner discusses the future. R. W. Fernstrum & Company is a third-generation, family owned business that manufactures heat exchangers, primarily for the commercial marine industry. In addition to its GRIDCOOLER line of keel coolers, it also manufactures and sells Weka Boxcoolers in the Americas and Tranter Heat Exchangers.

MN 100: R.W. Fernstrum & Company

P.O. Box 97 / 1716 11th Ave. R.W. Fernstrum & Company set the standard in marine heat exchangers over 65 years ago, building a reputation focused on innovation. Today, its commitment is to continual improvement, ensuring that customers have quality, reliability, and the latest in cooling technologies on your side. Over the years, R.W. Fernstrum & Company has grown into a worldwide organization with 24 representatives across six continents. Focusing exclusively on marine cooling…

Cool Runnings: R.W. Fernstrum's Engineered Solutions

A hallmark of the global maritime industry is the proliferation of smaller, family founded and managed businesses. R.W. Fernstrum is one such company: a ubiquitous presence for more than 65 years providing engineered cooling solutions to maritime and offshore markets. MR went to Menominee, MI, to meet with Sean Fernstrum and his team for insights on the unique products it produces and the markets it serves. R.W. Fernstrum & Company of Menominee, Mich., is a leader in engineering and manufacturing keel cooling technologies…

Ugly Ducklings & Steaming the Way to Victory in WWII

The design and construction of WWII Liberty cargo ships revolutionized shipbuilding by overhauling the blueprint process and standardizing on commonality of parts, welding, pre-fabrication and assembly line construction. Give me Liberty, or give me death!” a rallying cry of the Revolutionary War, got a second act in World War II. “Built by the mile and chopped off by the yard,” Roosevelt promised the no-frills Liberties would form a “bridge of ships” across the Atlantic. And they did. An exaggeration perhaps, but in truth, the Liberty wasn’t much to write home about.

Two boat service returns to Port Townsend/Coupeville

Full service will resume Friday on the Port Townsend/Coupeville route when the 64-car Chetzemoka returns to service for the noon sailing from Port Townsend. The vessel was pulled from service Tuesday so shipyard craftsmen could install a new keel cooler. “We met our goal to get the Chetzemoka back into service for the busy weekend,” said Assistant Secretary David Moseley. “It couldn’t have been accomplished without the hard work of ferry and shipyard employees. The Chetzemoka was towed on Tuesday to Dakota Creek Industries in Anacortes for drydocking.

Chetzemoka Stays in Service During Busy Summer Weekends

Vessel will go to drydock for repairs mid-week. PORT TOWNSEND – The Port Townsend and Whidbey Island communities have been seeing record-breaking numbers of tourists as vacationers take advantage of the last few weekends of summer. To help accommodate another influx of tourists expected this weekend, Washington State Ferries (WSF) is scheduling needed repairs to the Chetzemoka for mid-week. WSF has been running the Chetzemoka after temporary repairs were made to the vessel last week, but yesterday a custom-manufactured part arrived from Wisconsin and the vessel has been scheduled for drydock.

Tin Dredges: Thai Built and Operated

"We hire a new crew to build each dredge," said Khun Songpon, "My father, Yongyut Junsiri, trains them as they build the dredge then the same crew operates it in Indonesia. It is a brilliant innovation, but not surprising from a firm that can draw on the 35-year experience of its president Yongyut Junsiri in both the design and operation of dredges. In recent years the opportunities for tin dredges have centered on Indonesia. However it is experience gained in dredging Thai waters…

R.W. Fernstrum Comments on Gridcooler Use in the GOM

In response to concerns, R.W. Fernstrum recently reassured its customers that Fernstrum Gridcooler Keel Coolers are designed specifically to keep pollutants such as crude oil out of the cooling circuit to which they are connected. They are currently in use world-wide in oil skimming vessels as well as a variety of fishing vessels, supply vessels, work boats, pleasure craft, and numerous other vessel types. Many variables may affect the efficiency of the keel cooler while operating in oily water, but the operator should still be able to operate at reduced capacity. Seawater temperature, physical properties of the oil, oil to seawater ratio you are operating in, hull speed through the oily water, and water depth could all affect the potential efficiency of the keel cooler.

What is in John Garner's Pocket

You don't really know a boat until she's hauled. Plying her trade on the water, her best half's submerged out of sight. We think we recognize her - "oh, there's Odin," or "Shelby Rose," or "Twintube" - but what are we seeing? The lines of the deckhouse, the shape and placement of the wheelhouse, the arrangement of the stacks? These are the parts known as the superstructure - "super," in this case, meaning simply "upon." It's a little like saying we recognize someone by his hat. The boat's defining structure starts at the main deck and goes downward from there. What little we see of it is low on the horizon. There's the deck's line, along with a smattering of bulwarks.

Duramax Marine Creates Largest Ever DuraCooler

Duramax Marine LLC creates a DuraCooler of seismic proportions with its largest keel cooling system to date. Created for Astromaritima’s supply vessel, the Astro Vermelho, the DuraCooler measures 32 tubes wide by 16 ft. long. A first of its size for Duramax Marine; the previous largest DuraCooler was 24 tubes wide. Headquartered in Rio de Janeiro, Brazil, Astromaritima owns and operates supply vessels for the oil company Petrobras. “The service provided by Duramax Marine has been excellent, and the results of the DuraCoolers now on the Astro Pargo and the Astro Vermelho are extremely beneficial for our company,” as stated by Astromaritima’s technical department. Modifying the Astro Vermelho was more complicated than the previous modification of the Astro Pargo.

Propulsion Updates:Cummins Introduces the QSK60

Cummins literally unveiled its QSK60 powerplant to the marine market at the Workboat Show in New Orleans, ushering in a new, more powerful age for the surging diesel engine manufacturer. "This engine will take Cummins into new markets," said Geoff Conrad, general manager, Cummins Marine. The new engine (new for the marine market, that is) has a power range of 2,000 to 2,300 hp (1,492 to 1,716 kW for propulsion and 1,500 to 1,825 kW for auxiliary applications, and is now the most powerful in the Cummins line-up. "The QSK60 provides operators a new choice as well as a cost effective alternative to medium speed," Conrad said. The QSK60 is manufactured at the Daventry Engine Plant in the U.K., the same facility that builds the K38 and K50 engines.