New CO2 Vessel, Tank and Cargo Handling Concept Unveiled

A new tank concept for liquefied petroleum gas (LPG) and carbon dioxide (CO2) transportation promises to more than double current vessel cargo capacity, representing a step forward in the development of maritime transport solutions for the expanding carbon capture and storage (CCS) market, which will require maritime transport of liquefied CO2 to scale up rapidly.

The new design, which is based on existing, proven technology, has been developed by automation, gas and system integration specialist, Høglund Marine Solutions, in collaboration with Oldenburg-based HB Hunte Engineering, following a proof of concept request from gas technology experts.

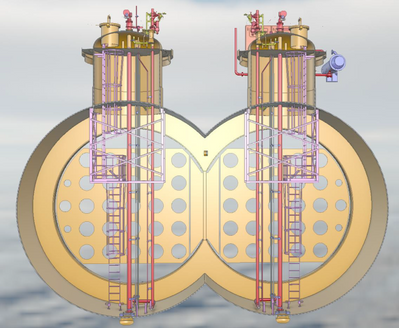

Høglund and HB Hunte’s transportation solution uses a unique bilobe tank with a capacity of 8,000 cubic meters, drawing on cargo handling system (CHS) and tank designs that they have previously proven in liquefied natural gas (LNG), LPG and other sectors.

The solution is readily available for use in existing tanker designs. It more than doubles the transportation capacity of liquid CO2 over current vessel capacity without the size, weight and stability concerns that would have come from a higher capacity “monolobe” design. It can be quickly adapted for LPG, giving extra flexibility to a vessel that uses them.

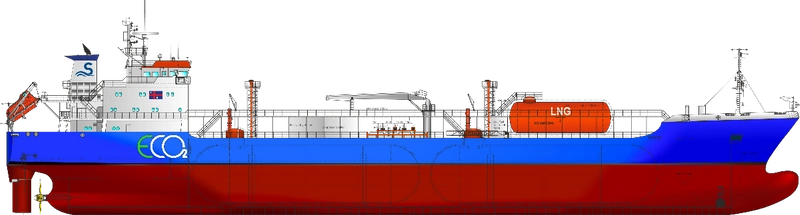

The solution is readily available for use in existing tanker designs. (Image: Høglund)

The solution is readily available for use in existing tanker designs. (Image: Høglund)

According to its developers, the tank configuration has a direct and positive impact for the use of different alternative material and reasonable fabrication processes while complying with IGC Code and conventional rule. This allows the production of a solution which is substantially lower cost and risk than conventional very large diameter cylindrical type offering the same capacity.

Currently, the maximum capacity for transporting liquefied CO2 is approximately 3,600 cubic meters, or roughly 1,770 tonnes in dedicated CO2 tankers predominantly with specialist operator Larvik shipping who has been transporting CO2 since 1988. However, as CCS chains develop, it is expected that maritime transportation capacity will need to increase significantly, requiring innovation in tank design and cargo handling systems.

“With the global economy facing more pressure to reduce its carbon emissions, we must develop the technology for a viable CCS chain, and new ways of solving the complex challenges that come with upscaling CO2 transportation,” said David Gunaseelan, Vice President of Sales and Marketing at Høglund, who added that the new solution developed with HB Hunte “significantly broadens our horizons and demonstrates the cross-sector thinking needed to reduce atmospheric carbon levels in as many ways as possible.”

Wolfgang Franzelius, Director Sales & Business Development at HB Hunte, said, “CCS is a core technology area in realizing the important goal of a net-zero economy. With new lines of finance emerging that support decarbonization, we must develop the technology to achieve it at pace and scale.”