Furgo’s New Offshore Wind Farm Drill Readies for Action

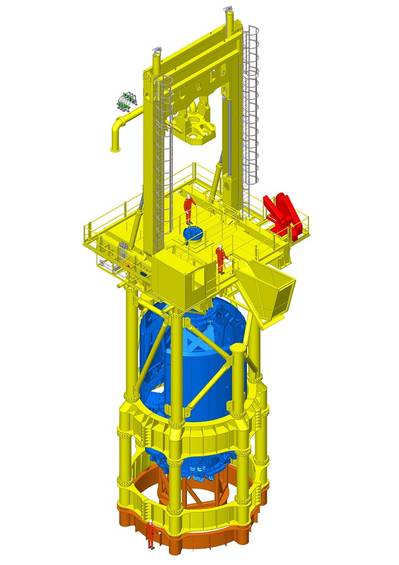

Specialist overwater drilling and marine construction contractor Fugro Seacore is building a pile top drill, the T120, for the offshore wind farm market to assist with monopole installations of up to eight meters diameter. Their current big drill has 90 metric tons of rotational torque; the new one will have 120 metric tons. This new addition to the fleet means they will have two drills capable of relief drilling piles of larger than six-meter diameter simultaneously, for instances where larger monopiles are the chosen foundation for the wind farm sites of Round three in U.K. waters and elsewhere in the European market.

A range of other downhole equipment has been produced, or is in production, to meet the needs of the offshore wind market. The latest drill bit is designed for up to seven meters diameter and is ready for deployment at Westermost Rough offshore wind farm. It will enable relief drilling services on 6.5-meter diameter monopiles where boulders or harder ground may be encountered. For the same project Fugro Seacore has also designed a new conductor (the lattice structure under the drill) so that equipment can be stored vertically - saving valuable deck space - and installed quickly as a single unit onto the pile.

“Our drilling rigs and associated equipment are custom built with specific markets and projects in mind,” explained Alun Jones of Fugro Seacore. “We are constantly seeking to expand the parameters of drilling technology and enjoy rising to challenges, such as recently completing a 6.5-meter diameter by 63-meter deep shaft – the largest drilled marine socket in the world.”

The entire pile top drill set-up, weighing approximately 350 metric tons, will be complete next month (December) and on site in early February 2014. In designing this new set-up the drill deck has been kept small to avoid conflict with pile gates and hydraulic power has been increased using electro hydraulic power packs.

Fugro Seacore is expecting drilling rates of up to 2.2 meters per hour - the same as those achieved with their T90 drill at Gwynt y Môr offshore wind farm, where the company was brought in to improve upon the rates that were previously being achieved.

This new drill will be the fifteenth pile top in the Fugro Seacore fleet and it will enable them to drill a full range of holes from 500 millimeters diameter up to eight meters diameter. They are looking forward to putting the new pile top into action and continuing to develop solutions for their clients.

Fugro Seacore’s fleet of jack-up barges and bespoke geotechnical and construction drills enable site investigation and construction work to take place in the most hostile and technically demanding environments. Flexibility and substantial plan resources ensure cost-effective solutions to exacting marine engineering challenges.

fugroseacore.com