“We are living through one of the most exciting periods in the history of the maritime industry,” said Juha Koskela, Managing Director, ABB Marine & Ports.

ABB, a company with its sights set on spurring the next step change for vessel and fleet management, has laid out its new approach “harnessing the full potential of its power, control and automation solutions” via digital integration.

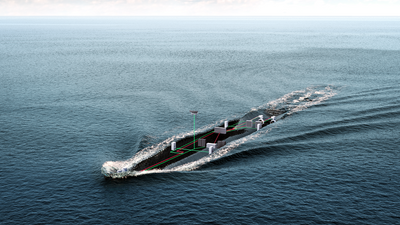

“We believe the next generation of ships will be electric, digital and connected as the industry moves towards the use of new energy sources and automated ship operations,” Koskela said. “Electric. Digital. Connected. encapsulates ABB’s drive to deliver solutions that make the maritime industry safer, more efficient and more sustainable based on a holistic perspective.”

ABB sees the automotive industry as a precursor to the maritime industry as it anticipates electric systems and autonomous control sets to be more widely adopted. “Based on greater efficiency and sustainability, electric propulsion will become a maritime imperative rather than an alternative,” ABB said.

In terms of on board layout, pure electric power and propulsion are simpler and less exposed to wear and tear compared combustion engines alone, noted ABB, whose electric systems presently help to achieve efficiency gains on more than 1,300 ships globally.

The company noted that electric power plants on board vessels not only optimize fuel consumption and maximize operational flexibility, but also allow for new energy sources such as batteries and fuel cells (ABB announced last week the first fuel cell system was delivered for Royal Caribbean).

Electric power and propulsion technologies also lend themselves to provide “a unique platform for digitalization,” according to Mikko Lepisto, Head of Digital Solutions at ABB Marine & Ports.

“They are inherently connected, which makes it significantly easier to apply automation and software solutions,” Lepisto explained. “This allows our customers to collect and analyze more data, make better decisions and ultimately improve performance. Furthermore, greater connectivity to shore and ever-increasing computing power, including machine learning, make it possible to exploit advanced analytics that feed into tools for energy efficiency and maintenance optimization.”

Even for shipyards, the case for more electric, digital and connected ships is compelling, Lepisto said: “Because we integrate our electric, automation and digital solutions in the design phase, shipyards can reduce cost, schedule and risk.”

ABB has invested heavily in technologies such as shore-side expertise, advanced analytics, software solutions and engineering availability, offering ABB Ability, a suite of digital and connected solutions that includes ABB Ability Marine Advisory System - OCTOPUS vessel operations and energy management optimization, for example. More than 700 vessels are already connected to ABB Ability Collaborative Operation centers, availing themselves of 24/7 troubleshooting, maintenance planning, benchmarking and predictive interventions, improving overall vessel performance.