Tech File: Battery Power Breakthrough in Ice

An ABB study based on three years of operational ship data mounts a case for integrating battery power onboard modern icebreakers, writes Samuli Hänninen, who specializes in icebreaking vessels at ABB Marine & Ports.

The maritime industry is still at the formative stage of realizing the gains available from batteries, but the ability to scale up to megawatt-hour levels is not the only attraction for the zero-emission technology. Evidence newly disclosed by ABB suggests that the improvements made to power efficiency and responsiveness can make a decisive difference for the performance of icebreakers operating in extreme conditions.

Demanding high installed power, icebreakers should also be efficient across a wide variation in power needs, especially given that they operate in areas where emissions face particular scrutiny. However, conventionally the need for high dynamic loads is met by oversizing generators running on fossil fuel – a solution which is highly inefficient when engine loads are low.

Slow load ramping is also a common problem for diesel engines, while new generation LNG engines are even less responsive. At the propulsion controls, icebreaker operators are often ready to respond but left waiting for engines to ramp up. Time lags like this can encourage what some call a conservative approach to operations, and others call out as inefficient: if an engine takes 10 minutes to warm up to 100 percent power, crew operating at loads in the margin between two and three engines will prefer to run continuously on three.

Battery power integration by ferry and cruise ship owners offers strong guidance on the way instantly available stored energy can improve the performance of other ship power sources by assisting peak shaving or spinning reserve, as well as providing a zero-emission power alternative. Understandably, newbuilds account for the vast majority of battery installations to date, but the number of cruise, ferry and cargo ship retrofit projects is growing.

Cold Hard Evaluation

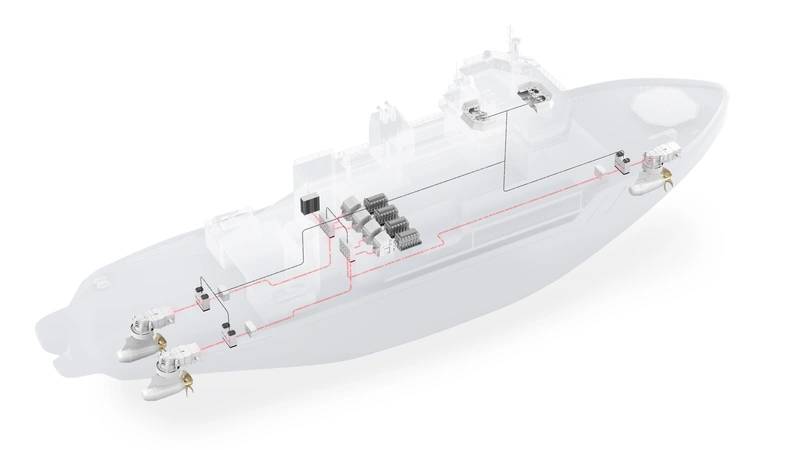

As one of the leading companies driving sea-going battery power, ABB has evaluated the impact of installing an energy storage system (ESS) onboard icebreaker Polaris. Delivered in 2016 but still one of the most advanced icebreakers in the world, Polaris was the first ship in its class to run on liquefied natural gas (LNG), driving four Low Pressure Dual Fuel (LPDF) engine driven gensets. The vessel is owned and operated by the Finnish state-owned company and has combined electrical power plant output of 22.5 MW.

Like many icebreakers before it, Polaris features an Azipod propulsion system from ABB – in this case two 6.5 MW stern units and one 6 MW bow unit from the Azipod VI product family ranging from 6-17 MW, developed and tailored for icebreaking vessels. The high torque induction motors in the propulsors come with a simple and durable construction and can deliver up to 180 percent of over torque, ensuring that the propeller rotates even during the heaviest ice interactions.

Plug-in Simulation

Using data drawn from three full winter seasons operating in the Bay of Bothnia, ABB’s Polaris study sets a new precedent in evaluating the impact of ESS technology on a new ship type.

With an overall objective of simulating a battery system that could absorb large load variations, to improve fuel efficiency and ramping capability, ABB uploaded powerplant load profile data from real operations in ice to a MATLAB file. The model evaluated the impact of an ESS Installation on total greenhouse gas emissions, primarily CH₄, in addition to reducing fuel consumption and improving the dynamic performance of the system.

The model worked using a hybrid power system that was simplified in comparison to real operations onboard Polaris, to consist of four main generators (auxiliary generator was excluded), one 4.5MWh and one main system load, with the battery to be charged from the generators. The dual-fuel engines were simulated to operate in gas mode or in diesel mode, with experience-based assumptions made on reduced engine efficiency at lower loads. A linear correlation between load fluctuations, fuel efficiency and CH₄ emissions was also assumed.

Based on a profile that saw Polaris at sea for four consecutive weeks, around 4,000 hours of operations were modelled over a 28-month period.

In the anecdotal example given, a conventionally powered ship working in ice-infested waters and operating at loads at the margins between two and three engines was maintained on three engines, based on the precautionary principle. However, the instant availability of additional power from a 4.5MWh ESS implies room for manoeuvre. The ESS will provide immediate propulsion power to cover the time it takes for additional main engines to come online, for example.

In the scenario given, safe operations should be possible for more of the time with two engines online supplemented by peak load battery power. From the Polaris simulation, ABB suggests that the immediate availability of power as needed would reduce main engine usage hours by up to a very substantial 46 percent of online time, with consequent fuel and emissions savings, and other knock-on benefits for maintenance and through-life cost.

Icebreaker Moves Ahead

Together, the operating profile and expectations on environmental footprint make the vessel type the ideal candidate to exploit the peak loading, spinning reserve and zero-emission power capabilities available through integrating batteries into propulsion. For LNG, ABB’s simulation suggests that including the ESS onboard Polaris would result in a 38 percent CH₄ reduction, 16 percent less fuel consumption (based on 46 percent reduction in engine hours); for diesel, the result is a 10 percent reduction in fuel consumption, 36 percent reduction of engine hours.

By being more responsive to power load needs, the addition of the ESS will also improve the icebreaker’s overall safety margin: an icebreaker engine working to overcome an ice ridge can be exposed to sudden over torque condition, for example; the power ramp with an onboard ESS-equipped vessel is no more than 10-12 seconds.

Despite the limitations of the model, ABB concludes that it is evident from the simulations that installing a battery can play a positive role in the power system of ships like Polaris. As well as reducing the number of engine running hours, the specific example highlights that the use of batteries would also lead to a reduction in the methane slip.

In addition, integrating battery power may be a route to broadening the safety envelope of icebreaking in a way that could allow for reduced installed power/number of main engines. It may be argued that, if most situations requiring full ahead power are relatively short in duration, it would be feasible to increase the capacity of the ESS and do away with one main engine. In some applications, ABB believes this is worthy of further study.