Waller Marine to Develop New LNG Terminal Facility

Innovative Waller-Designed Transport Vessels to Support Distribution

Waller Marine, Inc., through its LNG development subsidiaries, Waller Energy Holdings, LLC and Waller LNG Services, LLC, (the Company) has initiated activities on its first natural gas liquefaction (LNG) facility to be constructed on a 175 acre site the Company has acquired at the entrance point of the Calcasieu Ship Channel in Cameron Parish in Southwest Louisiana. Using small-scale liquefaction technology, the Company plans to install nominal 500,000 gallon per day LNG trains in phases as the market and demand for marine LNG fuels inevitably expands. The first trains are planned for the Waller PointTM LNG terminal in Cameron Parish, and additional trains are planned for a second terminal which it is developing through its subsidiary Waller Energy Partners, LLC, at a site to be secured on the Mississippi River in the first quarter of 2013. These will be the first two of the initial seven small scale LNG terminals the Company plans to install at strategic locations on each US coast.

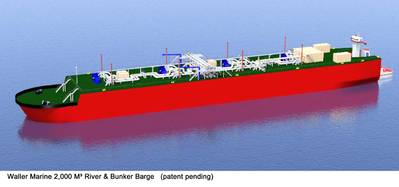

With the looming regulatory requirement for vessel’s to comply with new ECA emission control regulations when operating in the territorial waters of the United States, the Company’s focus is to supply LNG to the marine fuels market. To enable the supply and distribution of LNG to and from small scale LNG terminals and for bunkering LNG as a marine fuel, Waller has been the first to conceive and design a series of small LNG vessels ranging from its 2,000 to 10,000 cubic meter capacity river transport and bunker barges and its 10,000 to 30,000 cubic meter coastwise ATB LNG vessels. Waller’s innovative concepts are patent pending before the USPTO, and Waller has recently acquired Approval in Principle from the American Bureau of Shipping (ABS).

US vessel owners are faced with increasing costs of operations as the ECA regulations drive decisions on how they should comply; one, by installing scrubbers in the exhausts or two, by using ultra-low sulfur fuels. A third and more cost-effective alternative that will permit compliance with emissions is the use of LNG to fuel their vessels. With strategically located LNG supply facilities, a distribution of the fuel by Waller barges to small-scale LNG storage terminals combined with ship fueling with Waller LNG bunker barges at anchorages, ports and terminals throughout the US, vessel owners will have access to competitively priced LNG. Waller anticipates that substantial savings can be achieved by vessel owners using LNG fuels with payback for conversion costs being as short as six months.

Waller has also initiated a vessel conversion strategy and is working with partners on providing funding for the conversion of ships to be fueled by LNG. Working with engine manufacturers and equipment suppliers, Waller is engineering shipboard LNG fuel storage and supply systems for vessels having a range of horsepower. “They are also developing pre-manufactured systems to reduce or eliminate downtime during conversion.