Marine & Offshore sector: a complex and sustainable world of transformers

Today, in the transformers market and especially in the marine & offshore application, a new trend is gradually establishing: the use of green technology with full ambient compliant transformers that are recyclable and not polluting, which can be used in outdoor application, where typically companies use oil solutions instead.

A very clear tendency in this context is the use of electric ferries. These ferries typically carry batteries that must be charged quickly at the port in order to withstand the entire journey to the port of arrival.

The transformers required are very special, typically with several secondaries, with particular impedances and need to withstand a large load for a short period.

TMC Transformers has been participating in the design and manufacture of the transformers in several of these projects during the last two years, in collaboration with the engineering of several important ship designers. All this must be complemented by a dedicated and expert service department. Repair operations on board are sometimes complex and often urgent, so the personnel dedicated to this task needs to be top-notch. 24/7 availability is required.

TMC transformers installed on ferries and boats (image c/o TMC Transformers)

Moreover, the marine sector is very demanding, not only technically but also in terms of project management. It is necessary to have professionals with extensive experience in this highly specialized area.

Technically, this market is heavily regulated by several standards and certifications that managers must know perfectly. In addition to the design itself, an analysis of structures by finite element approach helps to verify the feasibility of the proposed solutions.

One of the differentiating features in a marine transformer is the type of cooling. This will influence not only the size and weight of the final solution but also its efficiency and resilience to failure. The most common cooling types are Air Natural (AN), in which the transformer does not require external cooling support, and Air Forced - Water forced (AFWF) where the transformer requires a highly specialized air-water heat exchanger integrated in its enclosure, where water is used to cool down the air inside and consequently, the transformer’s coils.

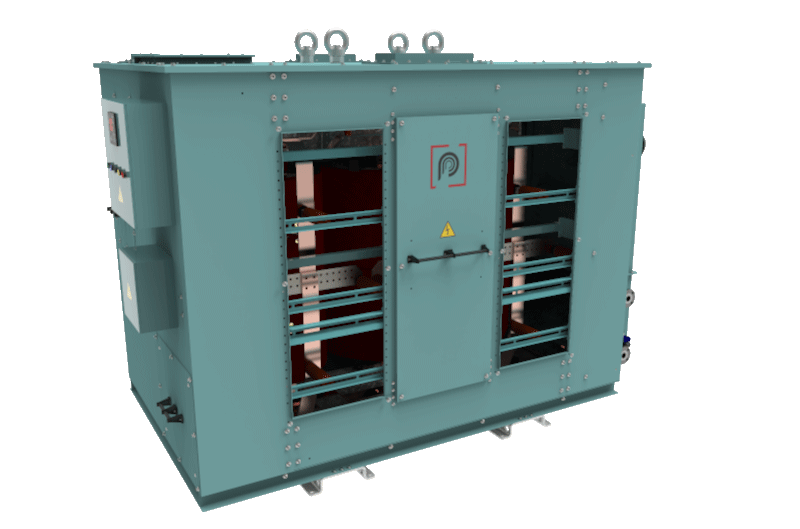

MARINE MV APPLICATION (image c/o TMC Transformers)

Another common characteristic is the use of integrated pre-magnetization transformers to help with inrush currents that can damage the main transformer.

Lastly, given the environment where these transformers have to work, a proper corrosion protection (metal treatments and painting) is necessary.

To consolidate the brand in this important sector in the world, TMC is going to participate at EUROPORT fair in Rotterdam from the 2nd to the 5th of November. If you want to know more about our competencies, come visit us!