Wärtsilä Wins Advanced Lube Order

Wärtsilä has been awarded a contract by DSD Shipping AS of Stavanger, Norway to retrofit the main engines on four DSD Shipping vessels with the Wärtsilä Retrofit Pulse Lubricating System.

The Retrofit Pulse Lubricating System (RPLS) is designed to lower the oil feed rate to the engine, thus cutting the consumption of lubricating oil. This creates savings in operating costs, and also has a positive effect on exhaust emissions. The DSD Shipping contract is Wärtsilä's first order for the retrofitting of small bore two-stroke engines with this system.

The order calls for the sale, installation and commissioning of RPLS on the Wärtsilä main engines of four DSD Shipping vessels. Three vessels (Stavanger Bay, Stavanger Viking and Stavanger Blossom) are equipped with 6-cylinder RTA58T engines, and one vessel (Stavanger Prince) operates a 7-cylinder RTA62U. The vessels are all approximately 105,000 dwt, and were built during the past eight years.

In addition to the RPLS, the installation will include the MAPEX-PR online liner wall temperature monitoring and alarm system, and a propeller shaft power measurement system.

Wärtsilä and DSD Shipping AS signed the agreement for these vessels in the fourth quarter of 2009. Delivery is scheduled within four months following the signing.

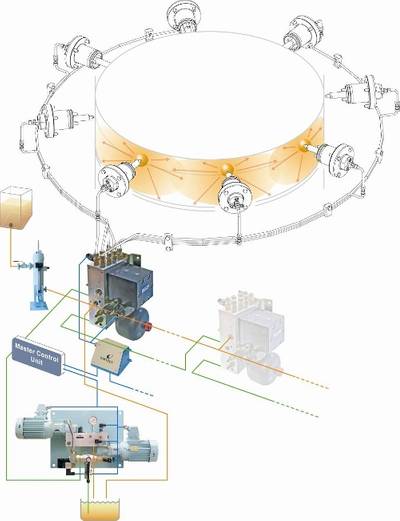

The Retrofit Pulse Lubricating System is a timed lubricating system developed by Wärtsilä. It distributes cylinder lubricating oil in pressurized pulses precisely into the piston ring package, where it is evenly distributed around the circumference of the liner.

This system was designed to retrofit existing Wärtsilä mechanically controlled RTA and electronically controlled RT-flex type engines. It is fitted as standard for new RT-flex and RTA type engines. The Retrofit Pulse Lubricating System is an example of applying electronic controls to engines already in operation in order to deliver improved performance and flexibility.

(www.wartsila.com)