New Anti-Fouling System from Cathelco

Cathelco has launched a new system which is specifically designed to protect box coolers against bio-fouling caused by barnacles and mussels.

Although Cathelco has protected box coolers in the past, this is the first time it has produced a system using anodes which are completely submerged instead of being inserted through the side of the seachest.

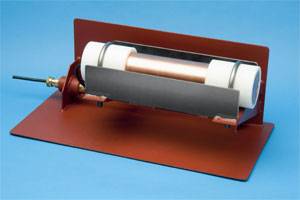

In the new design the anode is mounted horizontally beneath the cooling tubes and has cathode plates on either side to create a more even distribution of copper ions over the entire surface area. The ions create an environment where mussel and barnacle larvae do not settle or grow, avoiding the problems which are caused when they multiply and become encrusted on the cooling tubes. This reduces the efficiency of the heat transfer process resulting in engines overheating and increased fuel usage.

A purpose built mounting unit has been designed to hold the anode horizontally in direct line with the seawater flowing from the inlet to the cooling tubes. A cable exit boss is supplied by Cathelco with double watertight cable glands to produce an effective seal.

In common with Cathelco’s existing equipment, the box cooler system is based on the electrolytic principle where current is supplied to the anode from a control panel.

The first vessel to be installed with the new box cooler system is the Venus, an 282 ft (l.o.a) car ferry operated by the Swedish Road Administration on the short crossing between Svanesund and Kolhattan.

The system protects two seachests each containing four box coolers using two Cathelco anode units mounted beneath each cooler. The installation work was carried out by Marinprodukter, Cathelco’s Swedish agent.

(www.cathelco.com)