Ballast Water Tech: MOL

As ship owners globally face the eventual mandate to install ballast water management technology onboard their ships – a refit which is touted as the most expensive equipment refit ever – Maritime Reporter & Engineering News in its February 2013 edition examines emerging Ballast Water Technologies for consideration.

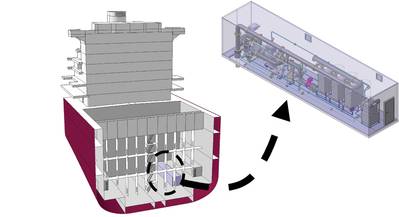

As shipowners globally wrestle with the daunting costs of installing soon to be mandatory Ballast Water Treatment Systems, a recent development from Japan is worth watching, as a new ClassNK approved technology – essentially “BWTS in a Box” – promises to offer faster installation time on an existing vessel, compared to systems installed in the vessel’s engine room.

Mitsui O.S.K. Lines, Ltd. received approval in concept for installation of a packaged container ballast water treatment system that can fit in a vessel’s cargo hold. The development is a joint technological development with Mitsubishi Heavy Industries, Ltd. and marks Japan’s first approval of such a system by Nippon Kaiji Kyokai (ClassNK).

In the system, a commercially available BWTS is packaged in a 40-ft. container complete with electric equipment. The system as presented cures a number of potential ills, including ease of maintenance and accessibility.

Characteristics of the container-type ballast water treatment system:

(1) Shorten the work required such for preliminary inspection because the system is containerized, allowing for a reduction of detailed pipe fitting and adjustment at the installation stage.

(2) Installation time is reduced by an estimated seven days, compared to installing a system in the engine room.

(3) Effective solution for vessels with limited engine room space.

MOL and MHI started detailed engineering work and will install an experimental system with a capacity of 750 cu. m./hr. (the first ever to fit in a 40-ft container) on the MOL-owned 8,100 TEU containership MOL Competence this spring.

Ballast water discharged while loading/discharging cargo carries marine organisms around the world and has fallen increasingly under the gaze of regulators, on the regional, national and international fronts, due to the documented negative impact on marine ecosystems and biodiversity. Accordingly, the International Maritime Organization (IMO) adopted the Ballast Water Management Convention in February 2004, and its ratification is under way.

(As published in the February 2013 edition of Maritime Reporter & Engineering News - www.marinelink.com)