Modern Power for Next-gen Bulk Carriers

WE Tech Solutions (WE Tech), an energy efficiency solutions provider in the marine industry, has received an order to deliver its direct-drive permanent magnet shaft generator solution to two new 25,600 dwt dual-fueled handysize bulk carriers, with an option for two more.

The Switch, a technology specialist of megawatt-class permanent magnet (PM) machines for advanced marine drive trains, will deliver the PM shaft generators to be used in the solutions provided by WE Tech. The vessels are owned by the Finnish ship owner ESL Shipping Ltd., and built at Qingshan Shipyard of Sinotrans & CSC SBICO in China. ESL Shipping Ltd. is the leading carrier of dry bulk cargoes in the Baltic Sea region. The ship owner chose PM shaft generator technology to support its sustainability strategy and start a new era in green shipping within pollution-sensitive seaways.

These new, ice-class 1A ships will be the first LNG dual-fueled handysize bulk carriers in the world, representing the latest in technology and innovation. The aim of these new-build vessels is to raise the bar when it comes to energy efficiency and sustainability. Thanks to the focus on environmental benefits and cost savings that the advanced technology can provide, the vessels will also be more profitable for their owners. “With the active front-end low harmonic drive technology (WE Drive™) and the permanent magnet shaft generator technology in our solution, the energy efficiency of the machinery reaches unmatched levels in the marine industry,” says Martin Andtfolk, Sales Manager of WE Tech.

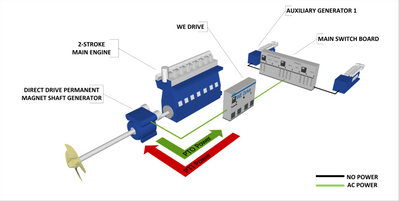

Using the Power Take Out (PTO) mode, WE Drive enables propulsion machinery to operate in combinator/variable speed while the direct-drive permanent magnet shaft generator produces electrical power up to 700 kW for the vessel’s electrical network. Significant savings can be achieved by drastically decreasing the operating hours of the auxiliary generators, as well as reducing the need for maintenance. Using the Power Take In (PTI) mode, WE Drive converts auxiliary generator power to propulsion power by employing the direct-drive permanent magnet shaft generator as an electrical motor. The solution is utilized to boost the propulsion system with 1250 kW mechanical power when operating in demanding conditions.

According to Mika Koli, Business Development Manager from The Switch: “The market has now recognized that a PM shaft generator is the most energy-efficient way to generate power in a vessel.” The choice of The Switch PMM 1000 shaft generator, the most common type delivered to date, is very suitable for this type of bulk carrier vessel. It is installed directly on the propeller line and allows extremely high energy efficiency, especially in part loads.

The delivery from WE Tech is scheduled for March 2017. The vessels will begin operation in the Baltic Sea in early 2018. “Our vision is 30% less fuel consumed in the global shipping industry by 2030,” says Mårten Storbacka, Managing Director of WE Tech. “This is a perfect example of implementing advanced drive train solutions for green shipping. ESL’s goal of operating extremely energy-efficient LNG-fueled bulk carrier vessels is further supported by the choice of The Switch PM shaft generator.”