C-Job says New Ship Design Tool Cuts Lead Time in Half

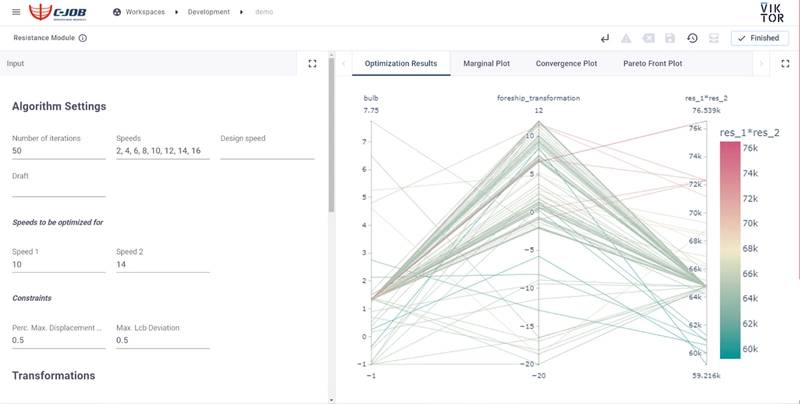

C-Job Naval Architects and VIKTOR have worked together on the ACD Resistance Module, a tool that will benefit shipowners during the ship design process.

“In the early phases of design, engineers must make decisions that can have an irreversible influence on later design stages," said Roy de Winter, R&D Engineer, C-Job Naval Architects. "Therefore, it is beneficial to make these decisions in a data driven way. An optimization process is difficult and labor-intensive work, but is essential for a reliable and efficient result. Together with the VIKTOR platform, we were able to create a tool, the ACD resistance module, that automates this process and reduces building and operational costs.”

The ACD resistance module optimizes a ship’s hull based on its resistance, which in turn C-Job says will result in superior building costs (CAPEX) and operational costs (OPEX) for shipowners.

The aim is to have the tool help to minimize the chance of having to make changes later in the process based on key-decisions made earlier in the design is reduced to almost zero, allowing for a smoother process during the whole ship design.

The ACD Resistance Module continues to build on previous work by C-Job, namely the accelerated concept design framework. This framework uses simulation software in combination with in-house developed algorithms to generate optimized concept designs. The ACD Resistance Module uses the latest algorithms created by C-Job. “Multiple algorithms were created and then added to C-Job’s ‘toolbox’ of optimization algorithms," said de Winter. "These algorithms allow for complex design problems to be optimized in significantly less time.” Image courtesy C-Job

Image courtesy C-Job