UK-based Cummins Darlington is celebrating its 50th anniversary during 2015. Since opening, around 1.5 million engines have been built in the factory for customers worldwide, providing power for vessels as well as land vehicles.

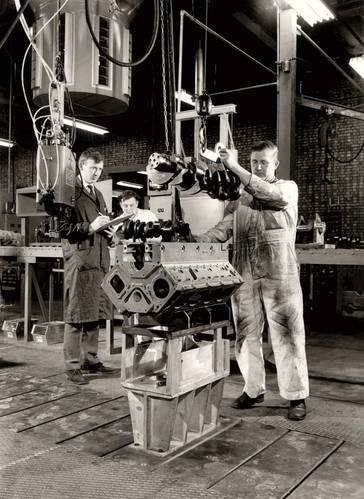

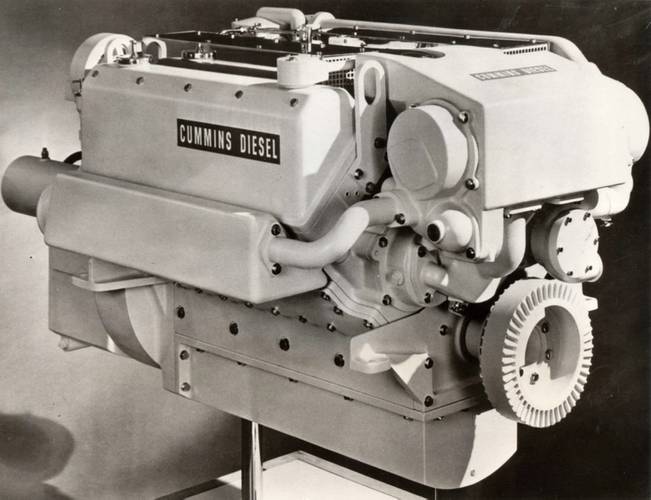

Work began in 1963 on the £8.5 million plant with engine production commencing in 1965, having more than 400 employees’ onsite. The production line assembled Cummins range of Small Vee V6 and V8 engines, named VAL and VALE. With cubic capacities of 5.7 and 8.3 liters, they had a capability of up to 111 kW, suitable for a range of boats at the time.

The Small Vee engines proved popular in the marine market and in 1966 a British offshore power boat Merry-Go-Round with twin Cummins broke the world water speed record for diesel power at over 60 mph. The record was achieved off the UK coast on Southampton Water. The two VT8 racing engines were each rated at 387 kW, especially for the event.

“The Small Vee was an evolutionary design at the time with some of the key features of the original engine carrying on into current products – such as an efficient high pressure fuel system, cylinder heads with four valves per cylinder, a rear gear train configuration, a high power to weight ratio, and major components with the latest materials designed for durability and reliability,” said Michel Kozulic, Marine Business Development Manager.

In 1986 an upgrade saw Darlington plant production move to the B Series engine. The 5.9 liter displacement was the forerunner of the latest 6.7 liter unit produced today.

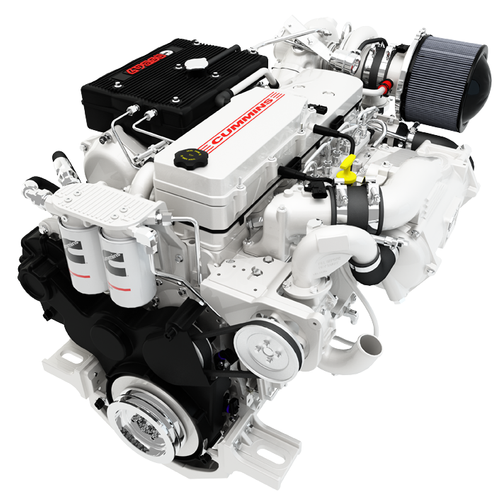

The current QSB6.7, built at the Darlington plant, provides between 172-410 kW, and up to 1,695 Nm in torque in an inline six cylinder configuration. It is driven through a Cummins wastegated turbocharger and a new 24 valve cylinder. The engine has a quiet operation, including an 80 percent reduction in noise at idle. It is also possible to maximize vessel performance and access comprehensive vessel diagnostic information via SmartCraft electronics. The QSB6.7 engine provides propulsion and power generation to many motor boats, and has recently featured in the Princess 43. A brand new SL option package is now available for the QSB6.7, as displayed at METS. This offers a lighter and more compact engine, allowing easy installation into the vessel.

The Darlington factory now employs more than 800 people and has a dedicated marine engine area onsite, a separate product development centre and a neighboring plant producing exhaust aftertreatment systems. £10.4 million has recently been invested into production and development at Darlington, supported by a regional growth fund grant. Marine engines from 6.7 to 11 liters (171-533 kW) are available from the Darlington site, including a range of helm to propeller packages.