Markey Engineers New A&R Winches for Offshore

Markey Machinery recently introduced its new line of Abandonment and Recovery (A&R) winches. Development of Markey’s A&R winches was facilitated through partnership with a world-wide service provider operating a fleet of marine vessels. The manufacturer says that the A&R machines are more cost effective in operation and maintenance requirements, thus making them ideal for oil field services such as maintenance, repair, and decommissioning.

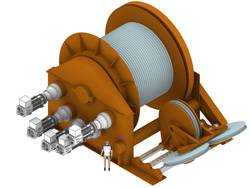

Markey’s type DEPS-76AR (see illustration) is a single drum, direct-pull type winch with level wind designed to work 3,300m of 4.75-in. (120mm) diameter wire rope. Redundant vector-motors developing 1,750 hp (1,310 kW) turn the drum through an induction hardened helical transmission. AC-variable frequency drives produce retrieval speeds of 32 m/min. and enabling torque control down to zero speed. Markey’s automatic Render/Recover controls is designed to tame peak loads while pulling in 450Tm- over cable weight.

The logistical demands of offshore oil and gas service-provider’s operations produced distinctive features - beginning with this machine’s mechanical arrangement. The form of the DEPS is single drum- direct pull style of winch. Traction heads, alternatively, require multiple sheaves to produce the same pulling force. Bending wire ropes produces uneven strand loading and internal friction leading to accelerated wear of expensive cables. The DEPS-76 is designed to maximize the working life of ropes. Service providers that couple properly engineered machinery with sound maintenance practices enhance on-site productivity realizing greater margins on each project.

Markey engineers design with a 34:1 D:d ratio - substantially larger and easier on the wire rope than the 20:1 D:d ratio of traction winch systems. The automatic fairleader withstands the breaking force of 4.75-in. (120mm) diameter wire. The drum-fairlead system carefully lays each adjacent wrap-protecting the exterior strands of the wire rope from abrasion. Sizing the drum to store the full scope of wire in eight layers benefits the performance of the winch and minimizing wire point loading. To make the machine more versatile, Markey’s engineers designed a field bolt-on wire rope kit to adapt DEPS-76 grooved drum cores and sheaves to different wire diameters- if needed. This advanced A&R machine is optimized and custom for a single customer’s application and specifications.

www.markeymachinery.com