LR: Flexible Ships Needed in Volatile Times

High or volatile oil prices and environmental concerns, point to the need for new designs capable of operating efficiently at different speeds. Lloyd’s Register warns that care needs to be taken when running at reduced power outputs.

Most container ships trading today, and on order, were designed for a world of relatively low energy prices. With oil at recent high levels many owners have been implementing or considering slow steaming strategies. Slow steaming may also be seen at present as an answer to over-capacity. But having reached historic highs of $USD 147 a barrel in July this year, the price of oil has fallen back to below $USD 100/barrel this week. As a result ship operators need to be prepared to manage high oil prices and volatility.

Container ship designs have reflected the prevailing price environment at the time of construction resulting in the delivery of ships that are highly unsuitable in future years when the oil price fluctuates. Operational flexibility, enabling owners to respond to different oil prices, is an area that Lloyd’s Register has been addressing.

Lloyd’s Register also believes that the industry needs flexible designs capable of operating most effectively across different power output bands.

Technical and economic research conducted by Lloyd’s Register is available to shipowners and shipyards to provide guidance when investigating solutions. Altering operational speed has substantial implications for both hull forms (slower ships can be boxier and, therefore, roomier) and for propulsion systems.

There are diminishing returns in slow steaming with machinery designed to operate at higher outputs - particularly when reducing speeds to below 20 knots. There are technical considerations involved in running at reduced power outputs: to ensure reliable operation from engines designed to run optimally at higher outputs, closer surveillance of engine performance and operating parameters, fuel quality, lube oil consumption and power-speed conditions will be required.

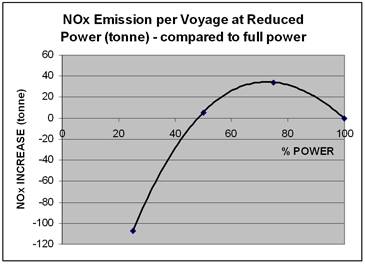

By way of example a relatively straightforward calculation demonstrates that for a large container ship designed for 25 knots at 70,000kW main engine power, speed reduction to 20 knots would require just 50% power. Given that voyage time will increase as a consequence of the reduced speed, the fuel saving will be somewhat less, about 40%. So slow steaming can offer a large saving in fuel consumption; however, it can be calculated that total NOx emissions increase - by up to 40 tonnes – when steaming between 20 and 25 knots.

From a technical classification perspective, owners looking to operate ships outside the recommended continuous operating design envelope should initiate careful analysis to ensure their engine operates reliably and it will not lead to consequences detrimental to safe, reliable ship operations.