Fugro-Rovtech Gets Subsea Simulator

Fugro General Robotics Limited (FGRL), supplier of subsea simulators, has delivered the first order for its next generation DeepTouch pilot training simulator to sister company Fugro-Rovtech. Fugro-Rovtech plans to use DeepTouch for the rapid evaluation of subsea intervention engineering designs as well as for pilot training.

“Fugro-Rovtech have a skilled engineering department and they will use DeepTouch not only for pilot training, but for engineering allowing them to do early trials of difficult engineering situations, from a conceptual point right through to having a pilot try it out in difficult sea conditions,” said Dr. Jason Tisdall, Managing Director of Fugro GRL.

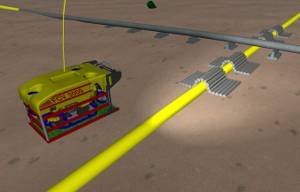

DeepTouch brings fully force-modelled physics simulation to subsea and ROV simulators so that any object in the world model both feels and behaves like the real thing. DeepTouch allows an engineer to drag and drop objects from the extensive libraries to build subsea worlds containing items such as vessels, pipes, cables and ROVs. Importantly, DeepTouch can also model ROV electrical and hydraulic circuits in great detail making it quick and easy to change the vehicle or tooling design prior to manufacture.

Until now, Fugro-Rovtech’s Engineering and Tooling department has relied on building prototypes, SITs, small scale wet tests, and the like for design verification. It now plans to conduct preliminary testing in the simulator during the design phase with the goal to greatly reduce overall lead times.

“We are talking about bespoke equipment we make for our clients such as tooling, control systems and other kit for the ROV,” said Nick Alvarado, Subsea Engineer, Fugro-Rovtech. “When clients encounter a problem subsea we occasionally have to design a set of tools specific to that job and sometimes the ideas and mechanisms have never been used before subsea, so being able to test before we actually start manufacturing is of great value.”

For training purposes, the underlying circuits are fully modelled which gives supervisors an overview allowing them to “break” individual circuits or components to test how much pilots understand their equipment. The supervisor can do this in real-time, or develop a problem scenario for trainees to resolve. Trainees can repeat a scenario until they get it right. The whole dataset and 3D world is recorded and can be returned to at any point for review.

www.fugrogrl.com