by Alan Haig-Brown

\While most boats have to find shelter or tough it out in heavy weather, the lift boat simply jacks up her hull and avoids the waves. Conventional vessels are often defined by their hull length, but it is the length of the jacking legs that is the significant number for lift boats.

Having recently delivered a lift boat with massive 320-foot legs, naval architect A. K. Suda, Ltd. are currently overseeing the construction of two of their latest designs.

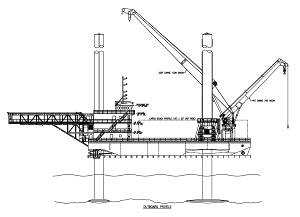

The larger of the two has 300-foot lift legs. Like most vessels of this type the beam, 118 feet, exceeds a 2:3 ratio relative to the 150-foot length. The length of the 300-foot legs is double the vessel’s length. The boat has a 12-foot 8-inch molded depth to its nearly flat bottom. Conventionally, there have been two approaches to liftboat designs. One is a scaled down version of the jackups. Some of these are being built in the Far East. Suda designs are not merely scaled down versions of jackups. They are “true liftboats”. Optimizing designs allows them to provide low coat stable work platforms (that are liftboats). The reduced hull weight allows for the use of durable, low maintenance jacking systems that are, once again, not an extrapolation of jackups. The referenced liftboat is an example of this design philosophy at work. Vessels of their similar design have been operating in other areas, incouding Angola, Africa.

Built to service oil industry production platforms, the lift boat has approximately 10,250 sq. ft (950 sqm) of working deck interrupted only by the two forward legs and a pair of cranes. This allows for a cargo block profile of 100x20 feet with a 48-foot width. The larger of the two cranes lifts up to 250 tons with a 130-foot boom. The smaller is a 40-ton crane with a 70-foot boom. A four level accommodation and navigation block shares the aft-end of the boat with the third leg. A heliport extends out from the stern. The arrangement with a compact accommodation block allows for a more efficient load distribution between the legs.

The SUDA 300-L3 model lift boat is propelled by a pair of EPA Tier 2 Cummins KTA38-M engines each delivering 850 HP to nozzled-propellers. These engines are grid-cooled and used only for propulsion while the hull is in the waters. A bow-thruster assists in positioning the vessel. Two Cummins-powered 625-kWe generators provide power for the hydraulic jacking engines, the cranes and general shipboard services. Two 250 kw generators provide primary power and backup servce for the ship service load. A 99 kw generator provides emergency power. Unlike some earlier lift boats, these engines are air cooled with deck mounted radiators to negate the need for hoses being lowered to the sea for water cooling when the vessel is jacked.

When fully extended, the legs can lift the bottom of the boat about 267feet off the sea bottom, with some variation depending on penetration of the foot pads in the sea bottom. When retracted for travel, the 80 square-foot pads at the bottom of the legss, are retracted into pockets in the bottom of the hull. The money-making part of the liftboat legs is the amount of leg extension below the hull. This vessel will boast of the highest leg extension as a ratio of its total leg length. Thus, it will compete with vessels of this type with anywhere from up to 20 feet higher leg lengths.

The SUDA 300-L3 model lift boat is currently under construction at Gulf Island Marine Fabricators in Houma, Louisiana. Delivery is scheduled for mid-2012.