Ship Maintenance Goes High Tech

Machine reliability is a top priority and continuing challenge in marine applications, which operate in harsh conditions and at remote locations far from port and repair facilities. Ship operators can help keep machinery running efficiently by equipping their maintenance departments and crews with a full complement of new-generation maintenance tools. These tools, which range from high-accuracy alignment systems to precise automatic lubricators, can help avert premature failures and reduce the need for repairs at sea.

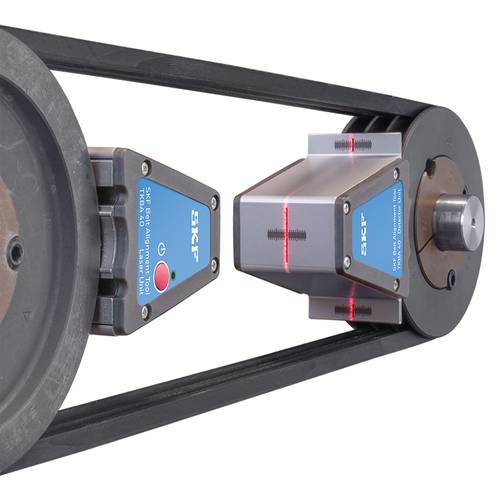

Tanker Operator Improves Pulley Alignment

Many ship operators have modernized their maintenance practices and tools as part of overall reliability efforts. A case in point is a major tanker operator with a fleet of 55 ships, based in the U.K. One pressing area of concern for the operator was pulley alignment. Belt failures in key machines had caused costly downtime and sometimes reduced a vessel’s operating efficiency. The root cause was usually misalignment.

The company decided to upgrade its existing alignment practices, which were cumbersome and lacked the necessary degree of accuracy.

The operator evaluated several advanced alignment systems and eventually opted for a laser-equipped belt alignment system consisting of a laser-emitting unit and a receiver unit. The two units are securely positioned in pulley grooves during operation, allowing the alignment of pulleys having varying widths and dissimilar faces. Users can detect horizontal, vertical and parallel misalignment and adjust belts and pulleys accordingly. The system’s design is intuitive, requiring minimal training for ship engineers.

After the upgrade, company officials reported an immediate improvement in alignment accuracy. The end result was more reliable machine operation across the entire fleet.

Matching Solutions

Different types of rotating machines have varying operating parameters and maintenance needs. Assembling a set of solutions that match the requirements of key application platforms prior to leaving port is a best maintenance practice. For example, new-generation maintenance solutions, such as single-point lubricators, can help optimize vibrating screen performance and cut the risk of failure. Vibrating screens are employed to sort the catch on fishing vessels and to transport certain bulk materials. In addition to harsh conditions, the screens experience high temperatures, acceleration and speeds ranging from 1,000 to 2,000 rpm. Common causes of failure include fretting corrosion on the shafts and lubrication and bearing cage problems.

Single-point lubricators attach directly to bearing positions in screens and supply a precise, regulated flow of lubricant. One popular type consists of a transparent canister filled with up to 125 milliliters of lubricant. Once activated, a built-in piston propels lubricant per the user’s pre-determined setting from the canister. Depending on the application and flow rate, lubricators can function for six months or more without a refill. This long shelf life can help avert the need for re-lubing at sea, which takes time and can introduce contaminants to the screen bearings.

Vibrating screens are typically driven by and coupled with electric motors and gearboxes. Like pulleys, they must be properly aligned with coupled machines for efficient operation. New hand-held shaft alignment tools generate real-time alignment values, enabling users to gradually adjust coupled machines until they are correctly aligned.

During screen operation, vibration-monitoring devices and electrical discharge detectors allow workers to assess machine health in real time. Vibration devices typically gather velocity and enveloped acceleration vibration data, compare it automatically with preprogramm`ed guidelines, and give early indications of conditions that may cause failure. Discharge detectors monitor operating electric motors, such as those driving vibrating screens, and identify potentially damaging electrical erosion. A similar set of maintenance solutions can be utilized for other marine applications, including refrigeration and ice-making equipment, conveyors, cranes, pumps and fans.

Mounting/Dismounting

Ship maintenance departments can benefit from the ability to mount and dismount rotating components at sea. Applications with large components can be designed beforehand to accommodate oil injection mounting/dismounting. Oil injection employs a thin film of pressurized oil to drive components onto shafts or safely remove them. For smaller components, portable induction heaters are ideal for on-board use. One ship operator in the Middle East, for example, acquired 20 high-frequency induction heaters for mounting bearings in small motors. The heaters weigh only 10 lbs. and are easy to handle and store. They heat bearings in bore sizes from 0.8 to 4 inches and weighing up to 11 lbs. An added benefit is that the heaters do not magnetize bearings while heating them. This reduces the risk of small-particle contamination and makes a demagnetization cycle unnecessary.

The Author

Paul Michalicka is North American area sales manager for maintenance products, SKF USA Inc., Lansdale, Pa. He can be contacted at

e: [email protected]

t: 416-806-6723

(As published in the June 2014 edition of Maritime Reporter & Engineering News - http://magazines.marinelink.com/Magazines/MaritimeReporter)