PPG Showcases Marine Coatings at SMM

PPG’s (NYSE: PPG) protective and marine coatings business will showcase four of its’ premium marine coatings solutions at SMM event in Hamburg. Amongst these is one of PPG’s most recent product innovations, the PPG SIGMAGLIDE 1290 fouling release coating. Its 100% silicone binder fouling release system utilizes a breakthrough dynamic surface regeneration technology to eliminate slime problems and dramatically increase fuel savings compared to existing fouling release products.

Industry Group Developing New Hull Coating System

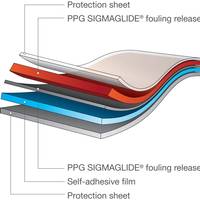

PPG’s protective and marine business has received EU Funding for a project which aims to produce a new fouling protection system for commercial vessels. A project development group including PPG, MACtac, Meyer Werft/ND Coatings, VertiDrive and Hamburg Ship Model Basin HSVA are currently working together to establish an automatic application process for allowing a self-adhesive/fouling release film to be used on commercial seagoing vessels. This process will allow shipowners and…

PPG Debuts New Antifoulings

Low-friction, self-lubricating coatings use patented technology to deliver reduced fuel consumption and improved tolerance to idle time. PPG Protective and Marine Coatings announced the launch of SIGMA SAILADVANCE, a new range of antifoulings suitable for a variety of operating conditions. The range currently comprises four coatings, including SIGMA SAILADVANCE RX and GX, two completely new formulations based on PPG’s own patented technologies. These antifoulings are based on…

PPG by the Numbers: 580, 690 & 700

PPG caps a busy 2013 by launching three separate coatings; each intended for a specific application. As regulatory and operational requirements drive coatings decisions, it’s increasingly clear that, on the water, one size does not fit all anymore. You can get there, nevertheless, by the numbers. It has been a busy year for PPG Protective and Marine Coatings (PPG). With at least three new marine product releases and even a new production plant in Poland, the Pittsburgh, PA-based global coatings and specialty products company hasn’t stopped long enough to give the proverbial barnacles the smallest chance to slow its growth. Founded in 1883 and operating in nearly 70 countries around the world, PPG’s sales in 2012 exceeded $15 billion.

Adances in Marine Coatings & Corrosion Control

The advance of modern marine coatings and related technologies is not unlike other technical sectors of the maritime industry, primarily driven by emerging regulation from the international, national and regional level, usually in regard to environmental concern. But in recent years, an increased focus on the reduction of marine emissions in tandem with the capability to more directly correlate clean, well-maintained hulls with reduced fuel consumption and lower emissions has driven the industry further faster…

Sigma Ecofleet 690 Provides Antifouling for Short Sea Shipping

PPG Protective and Marine Coatings (PPG) has launched Sigma Ecofleet 690, designed to deliver self-polishing antifouling for extreme and aggressive fouling conditions. Developed specifically for the dry dock, maintenance and repair market, Sigma Ecofleet 690 has been formulated using PPG’s unique patented binder technology ensuring consistent performance levels and fouling control for in-service periods of up to 60 months. Fully compliant with the IMO AFS Convention, the product…

Hempel Launch High-solid Anti-fouling Paint

Hempel launches high-solids versions of their Globic, Oceanic and Olympic antifoulings, which offer optimised features and stronger ROI. The new versions, Globic 9000, Globic 6000, Oceanic+ and Olympic+, have been optimised to offer the benefits of high-solids. Reflecting Hempel’s commitment to investment in R&D, they offer optimised binder systems, polishing rates, biocides and solids levels. In addition, they also feature microfibre technology, which works like steel reinforcement in concrete to deliver superior mechanical strength and elasticity.

Hempel Launches High-Solids Antifouling

Hempel is launching high-solids versions of their Globic, Oceanic and Olympic antifoulings, which offer optimized features and stronger ROI, according to the company. The new versions, Globic 9000, Globic 6000, Oceanic+ and Olympic+, have been optimized to offer the benefits of high-solids. Reflecting Hempel’s commitment to investment in R&D, they offer optimized binder systems, polishing rates, biocides and solids levels. Globic 9000 is Hempel’s new top-end antifouling. An evolution of Globic NCT, it can be specified for 90-month docking intervals. Globic 6000 is a new product in the Globic series, which builds on the same technology as Globic 9000. It is suitable for 60-month intervals.