BMT Subsea Technology for Equinor

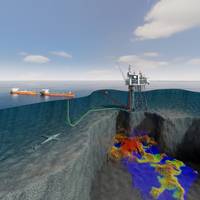

Global engineering company BMT announced a partnership with Sonardyne to deliver to Subsea 7 its proven ‘Riser Monitoring System’ (RMS).The subsea integrity monitoring solution has been adopted by the world’s largest spar platform, Aasta Hansteen.The Aasta Hansteen Spar platform is operated and owned by Equinor ASA, the Norwegian multinational energy company.Located 300 kilometres west of Sandnessjøen on the Norwegian Continental Shelf (NCS) in water depths of up to 1,300m, the deepest field development on the NCS, the Aasta Hansteen Spar is installed in a harsh environment utilising highly robust deepwater Steel Catenary Risers (SCR).Neil Charles…

Biggest Shear-Leg Floating Crane in Operation

On April 21, Hyundai-10000, Hyundai Heavy Industries (HHI)’s newest floating crane, succeeded to the throne of “symbol of HHI” from the two 1,600-ton gantry cranes at its offshore yard by lifting a topside module of Moho Nord tension leg platform (TLP) at once. What makes Hyundai-10000 a successor to the 1,600-ton Goliath cranes is not just because it is new but because it has an unparalleled lifting capacity at one of the world’s biggest offshore yards. Hyundai-10000 can lift subjects about six times heavier than the Goliath crane, hence its name.

Statoil: Polarled Pipe-Laying Kicks Off

On 26 March, the Solitaire pipe-laying vessel started on the first stage of the Polarled installation project. The 482-kilometre long pipeline will transport gas from the Aasta Hansteen field in the Norwegian Sea to Nyhamna in western Norway. Statoil is operator during the development of the Polarled project and therefore responsible for laying the pipeline between Aasta Hansteen and Nyhamna. As operator for the gas plant, Shell is responsible for preparing the Nyhamna processing plant for gas reception. “I am pleased to note that the pipeline is now connected to the Nyhamna processing plant. The pipeline pull-in to Nyhamna is an important milestone to the project and the Polarled licensees,” says Håkon Ivarjord, MPR’s project venture manager.

Subsea 7 Selects BMT for Offshore Deal

Subsea 7 selected BMT Scientific Marine Services (BMT), subsidiary of BMT Group Ltd, to supply the riser monitoring system for the Aasta Hansteen Spar, approximately 300 km off the coast of Norway. The system includes an innovative suite of remotely operated underwater vehicles (ROV) deployed strain, motion and position sensors to monitor steel catenary riser (SCR) response in the Touch Down Zone (TDZ). Data acquired by the riser monitoring system will be used to validate both the spar and SCR design.

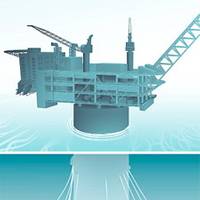

Wärtsilä Gas Units Selected for Largest Ever Spar Platform

A new spar platform being built for Statoil's Aasta Hansteen field off the coast of Norway will feature Wärtsilä's Inert Gas and Nitrogen Generator systems, the power solutions company said. The contract has been issued in the first quarter 2014 by Hyundai Heavy Industries (HHI) of South Korea, the yard building the platform. The Wärtsilä Inert Gas Generator will utilize titanium in its construction, the first time ever that this material has been used in such a system. Titanium was preferred due to its superior corrosion resistance in relation to sea water. Wärtsilä's claims its experience and technical expertise in gas handling systems were critical factors in the award of this contract…

The History of Offshore Energy

Offshore exploration is a history of man v. Prospecting for oil is a dynamic art. From a lake in Ohio, to piers off the California coast in the early 1900s, to the salt marshes of Louisiana in the 1930s, to the first “out-of-sight- of-land” tower in 1947 in the Gulf of Mexico, the modern offshore petroleum industry has inched its way over the last roughly 75 years from 100 ft. of water ever farther into the briny deep, where the biggest platform today, Shell’s Perdido spar, sits in 8,000 ft. of water. As a planet, we have two unquenchable thirsts – for water and for oil.

ABB Wins US$60-Million Statoil Offshore Contract

Power and automation technology group, ABB, informs it has won three orders worth $60 million for internal and external telecommunication systems for three Statoil projects on the Norwegian Continental Shelf. The three contracts have been signed with leading shipyards in South Korea. ABB will be a system integrator of telecommunications on the offshore installations built for the Aasta Hansteen and Gina Krog fields in the Norwegian sector of the North Sea and for the Mariner field in the British sector.

Kvaerner Gets Offshore Spar Topsides Sub-Contract,

Hyundai Heavy Industries (Hyundai) has awarded Kvaerner a sub-contract to provide services for inshore and offshore hook-up and commissioning assistance for the topsides for the Aasta Hansteen spar project. The inshore-work will be carried out at Stord and the offshore scope will be done at the field in the Norwegian Sea 300 km west of Bodø. Kvaerner explain that the inshore work will be carried out during the first half of 2016 while the platform is moored at Kvaerner's deep water site in Digernessundet, close to Kvaerner's offshore yard at Stord.

Lankhorst Wins Big Spar Mooring Contract

Offshore rope manufacturer Lankhorst Ropes has been awarded a contract by Hyundai Heavy Industries and Technip USA consortium (HHITECH) to supply the mooring lines for Statoil’s Aasta Hansteen Spar platform to be located in the Norwegian sector of the Norwegian Sea. According to Lankhorst, it is the largest single order for deepwater mooring ropes, and believed to be the largest ever order in the global synthetic fiber rope industry. Located in the Aasta Hansteen field, approximately 300 km west of Bodø…

Kværner to Play Part in Construction of Enormous Offshore Spar Platform

Norway's Kværner ASA say that Technip Norge AS has awarded them a sub-contract for the Fjord Base and Support Services up-ending and preparation for mating operations of the sub-structure for the Aasta Hansteen Spar platform. With a total length of 198 meters, Aasta Hansteen will be the world's largest spar platform, claims Kværner, and the first of its kind on the Norwegian continental shelf. Statoil has contracted Technip and Hyundai Heavy Industries (HHI) in a consortium to engineer, procure and construct (EPC) the Aasta Hansteen spar substructure.

First Subsea Awarded Heidelberg Spar Mooring Connector Contract

Deepwater mooring specialist, First Subsea Ltd has been awarded a contract by Technip Inc to supply the subsea mooring connectors for a 23,000-ton truss spar platform moored in 5,310ft (1,620 m) of water in Anadarko Petroleum Corp's Heidelberg field development in Green Canyon Blocks 859, 860,903, 904 and 948 in the Gulf of Mexico. The Heidelberg spar will be moored by nine Series III Ballgrab ball and taper mooring connectors attached to polyester mooring lines. The connector's…

Shell Sells Interest in GofM Holstein Field

Shell accepts US$560-million offer from Plains Exploration & Production (PXP for working interest in Gulf of Mexico Holstein asset. Shell received an unsolicited offer from PXP for Shell’s working interest. The transaction is effective October 1, 2012 and is expected to close by year-end 2012. Holstein is a mature deepwater asset and the sale is consistent with Shell’s continuing practice of reviewing our existing portfolio and evaluating new opportunities. The Holstein Unit is centered on a spar platform anchored in 1350 meters (4400 feet) water depth and first produced in December 2004. Shell’s 50% interest represents about two percent of the company’s overall Gulf of Mexico net production and had a 30-day net average production of 7.4 kboe/d prior to Hurricane Isaac.

Spar Hull Installation Contract for McDermott

McDermott awarded Gulf of Mexico Spar hull installation contract for Williams Partners. McDermott International, Inc. announce that one of its subsidiaries has been awarded a contract by Williams Partners L.P. for transportation and installation services for a Spar hull in the Gulf of Mexico. McDermott will transport and install the Gulfstar FPS GS-1 Spar hull and moorings. Located approximately 150 miles offshore, the Spar platform is destined for the Gulf of Mexico’s Mississippi Canyon and will sit in approximately 4,200 feet of water. McDermott’s recently improved DB50 vessel will install the moorings before transporting the classic-design Spar hull to the installation site where it will be upended and ballasted before installing a temporary work deck.

Technip Wins Key Offshore Engineering Contract

Technip was awarded a front end engineering design (FEED) contract by BP Exploration & Production Inc. This contract covers the design of a Spar* hull and mooring systems for the Mad Dog Phase 2 Project, located near Green Canyon Block 825 in the Gulf of Mexico. This first award comes under the framework of the 10-year Spar platform master services agreement signed in 2011. The Mad Dog Phase 2 Spar will be located near the first Mad Dog Spar delivered by Technip for BP in 2004, and installed on Green Canyon 782. Detailed engineering for the new Spar is scheduled to start during the second half of 2012. Technip’s operating center in Houston, Texas, will execute the contract with support from the center in Pori, Finland.

First Subsea Wins Technip Connector contract

First Subsea Awarded Lucius Spar Mooring Connector Contract. Deepwater mooring specialist, First Subsea Ltd has been awarded a contract by Technip USA Inc to supply the mooring line connectors for a new spar platform moored in 7,000ft (2,134 m) of water in the Lucius field, Keathley Canyon block 875 in the Gulf of Mexico. The Lucius spar will be moored by nine Ballgrab ball and taper mooring connectors attached to polyester mooring lines. The Ballgrab connector comprises a male connector and female receptacle. The Series III male connectors will comply with the new ABS Mooring Guide 2009.

Aker Solutions Designs World's Largest Spar Platform

Aker Solutions has been awarded a FEED (Front-End Engineering and Design) contract from Statoil to design the world's largest Spar platform for the Aasta Hansteen field development in the Norwegian Sea. With a total hull length of 193 meters and a draught of 170 meters, the Aasta Hansteen (formerly named Luva) Spar platform will be the largest of its kind. A Spar platform is a cylinder shaped floating offshore installation. Aasta Hansteen will be the first Spar platform on the Norwegian continental shelf (NCS), and also the world's first Spar platform with condensate storage capacity - a so called Belly-Spar. The Belly-Spar concept is an exclusive Aker Solutions design.

Technip Awarded Subsea Contract in Gulf of Mexico

Technip has been awarded a contract by Exxon Mobil Corporation for subsea equipment on the Hadrian South natural gas project in the Gulf of Mexico in approximately 7,500 feet (2,300 meters) of water. The project consists of a subsea tie-back to the planned Anadarko operated spar platform, Lucius(1). The contract covers project management, procurement and installation of two 7- mile-mile long flowlines(2) and associated jumpers, installation of a 9-mile umbilical(3), associated foundation and flying leads. Technip’s operating center, in Houston, Texas, will execute the contract. The flowlines will be welded at Technip’s spoolbase, located in Mobile, Alabama.

Statoil Moving Forward on Luva Field

Luva may herald start of deep-water development in Norwegian Sea. Statoil, together with its Luva field partners, has selected a Spar platform to develop the field. As a gas transport solution has also been decided, a major step has now been taken towards deep-water production in the Norwegian Sea. The Luva field, which is a deep-water pioneer in the Norwegian Sea, may be the first to have a Spar platform on the Norwegian continental shelf (NCS). The field is located outside of existing infrastructure and has a water depth of 1300 metres.

Keppel FELS 6th Drilling Rig for Seadrill

Keppel FELS Limited (Keppel FELS) is on track to deliver West Vencedor, the sixth of seven KFELS semisubmersible drilling tenders (SSDT) to Seadrill Limited before the end of 2009. The completion of this project on time and within budget, will top out a record year of 13 rig deliveries for Keppel FELS. West Vencedor is built to Keppel’s KFELS SSDT 3600E design which was conferred the ASEAN outstanding engineering achievement award in December 2009 for its eco-friendly features and sustainable operations.

First Oil from the Tahiti Field

On Wednesday, 6 May, StatoilHydro received first oil from the Chevron-operated Tahiti field in the US Gulf of Mexico. Tahiti is expected to produce 125,000 barrels of oil and two million cubic metres of natural gas a day, reaching plateau production later this year. With Tahiti on stream, StatoilHydro will more than double its production from the US Gulf of Mexico. StatoilHydro's interest in the Tahiti field was acquired through the EnCana Gulf of Mexico acreage acquisition in 2005, with Tahiti being sanctioned later that year.

CSO Aker Maritime Wins Multiple SPAR Delivery Contract

CSO Aker Maritime, Inc. (formerly Aker Maritime, Inc.), one of Coflexip Stena Offshore's Houston-based entities, has been awarded a contract for delivery of multiple SPAR floating production platforms for BP's deepwater developments in the Gulf of Mexico. CSO Aker Maritime, Inc. will deliver the SPAR hulls and mooring systems under a program calling for up to five SPARs. This award is the largest in scope and value for the CSO Group. CSO Aker Maritime, Inc. will be responsible for the engineering, procurement, fabrication and delivery of the complete hulls and mooring systems. The program contract calls for the first SPAR delivery in 2003.

McDermott Awarded EPCI Contract for Spar Project

J. Ray McDermott, Inc., a subsidiary of McDermott International, Inc., has been awarded a turnkey engineer-procure-construct-install contract to provide a spar platform for the Medusa Field Development Project, a deepwater development for Murphy Oil Corp. in the Gulf of Mexico. Financial terms of the contract are not being disclosed. SparTEC, Inc., a subsidiary of J. Ray McDermott, will act as the general contractor and overall project manager for the design engineering, procurement, fabrication, installation and commissioning of the Medusa offshore production facility, which will be located in 2,223 ft. of water in Mississippi Canyon Block 582. “We are extremely honored and excited to be selected by Murphy to bring Medusa to fruition,” said Bobby Rawle, president of J. Ray McDermott.

Deepwater Drilling Provides Good Long Term Prospects

According to the U.S. Department of the Interior's Minerals Management Service (MMS), deepwater drilling (1,000 ft. and deeper) shows the greatest potential of development, and certainly has garnered the attention (as well as the E&P dollars) of offshore oil production industry leaders. By yearend 2003, the MMS estimates as much as 63 percent of the oil production and 29 percent of the daily gas production will come from deepwater reserves. In August of 1998 there were 30 (temporary and permanent) deepwater rigs drilling simultaneously in the Gulf of Mexico's Outer Continental Shelf (OCS), at depths greater than this. The proliferation of deepwater development projects will likely continue to grow…