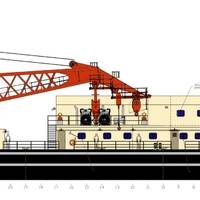

Conrad Wins Army Corps Crane Barge Contract

Conrad Shipyard won a contract to build a Crane Barge for the United States Army Corps of Engineers. The 300 x 68-ft welded steel barge is to be used in floating crane service by the Corps’ Rock Island District in support of its maintenance mission on the inland navigation system. The barge is designed with a deckhouse and crew support area, generator room, shop area, office and heads. Below deck will enclose machinery spaces, storage areas and tankage. The vessel will be classified by ABS as Maltese Cross A1…

Harvey Gulf ATB Earns ABS, USCG Approvals

Harvey Gulf International Marine (HGIM) announced it has received both ABS (American Bureau of Shipping) class functional approval and USCG (United States Coast Guard) design bases approval on a 4,000 cubic meter LNG articulating tug barge (ATB) construction drawing package; the design accounts for ship-to-ship transfer and shore side resupply transfers. Working closely with its design partner Waller Marine, and in conjunction with ABS and USCG HGIM has developed the design package…

Cathelco Supply BWT System for Cable Laying Vessel

Cathelco have supplied a ballast water treatment (BWT) system for the C.C. Pacifique, a steel barge which is being converted into a cable laying vessel for Coastal Carriers BV of the Netherlands. The order for the system was placed by V.Delta, part of V.Group, the international ship management company who are managing the conversion of the 120 meter vessel which is taking place in Singapore. The BWT system has a capacity of 300 m3/hr and has been supplied as a self contained skid mounted unit.

A Day in the Life of a Towboater

In early July, Raina Clark, Managing Editor for MarineNews, spent eight days on the Upper Mississippi and the Illinois Rivers on towboats — the Theresa Wood and the Thomas E. Erickson. Both vessels are chartered by AEP River Operations and owned and operated by Marquette Transportation. Raina traveled first aboard the Theresa Wood on the Mississippi River from Winfield, Mo. to Guttenberg Wis. Then she crossed the state of Illinois to catch the Thomas E. Erickson southbound on the Illinois River from Pekin, Ill. back to the confluence of the Mississippi River.

Vocational Training Options Grow

Vocational training options continue to expand since the STCW 1995 rules put a crimp in the hawsepipe. The Pacific Maritime Institute’s (PMI) Workboat Academy has graduated its third class of mates. The State University New York (SUNY) Maritime College has opened a new two-year engineers program. Finally, Kirby’s training school continues to provide company employees with an in-house route to the wheelhouse. “We made the decision in 1995 that we weren’t going to be able to rely on other entities to provide training for our people,” said Patrick Kelly of Kirby Corporation.

Greenstone II to Depart Port of Duluth-Superior

The tank barge Greenstone II, the first vessel to be built by Superior’s Fraser Shipyards in nearly 40 years, is tentatively scheduled to depart the Port of Duluth-Superior on Monday, May 24, the Duluth Seaway Port Authority reported today. Fraser Shipyard floated the Greenstone II at its dry dock today (May 21), and has scheduled the Marine Tech, Duluth, tug Miss Laura to escort the vessel to Houghton, Mich. The Greenstone II is a double-hulled fuel barge that will operate between Houghton and Isle Royale National Park, replacing the single hulled barge Greenstone that was retired last year. Fraser Shipyards, whose predecessors date back 113-years, is the only remaining major American shipyard and dry dock operation on the western end of the Great Lakes.

Positive Outlook for Global Subsea Development, Deepwater Strengthening

There are 2,511 identified pending, probable and possible subsea production wells forecast (base case) worldwide over the next six years. Some 18 percent of these subsea completions will be installed in North America, 30 percent in Africa/Mediterranean, eight percent in Asia-Pacific, 26 percent in the North Sea and 18 percent in Brazil. These subsea projects are in various development stages, including: 23 percent at the pending/construction stage, 11 percent bidding, 9 percent in detailed engineering, 16 percent at the front-end engineering design (FEED) stage, 16 percent of the wells probable and 26 percent possible indicating possible development in the future.

Conrad Industries Announces New Contracts and Deliveries

Conrad Industries, Inc. announced the signing of contracts during the first quarter of 2007 for the construction of six vessels and the recent delivery of various vessels. Blessey Marine Services, Inc. contracts for two 8,400 bbl. double skin stainless steel tank barges. D, grade A and lower flammable or combustible cargos. market. deck barge. In addition, Gulfstream Rental Tools, Inc. contracts for three 120'x30'x7' shale barges. bunkering barges for their west coast operations. skin tank barge has a capacity of 26,000 bbls. of fuel. Classed and equipped with a complete cargo loading and off-loading system. liquid overfill protection system. boats for the Corps of Engineers. boat is for Corps' St Paul District. accommodations for 10 persons. Upper Mississippi River.

MFI Selected to Supply for Greenland Pier

Marine Fenders International, Inc., a manufacturer of marine fendering systems, was selected to supply our Ocean Guard Netless foam filled marine fender system for the one of the harshest marine environments in the world, the DeLong Pier at the Thule Air Base in Greenland. The Maintain DeLong Pier project is located at the DeLong Pier along the Waterfront. The maximum mean daily temperature is 7° C (44° F) in the month of July, with a minimum mean daily temperature of -29°C (-20° F) in the month of March. The DeLong Pier was constructed circa 1950 and is a prefabricated steel structure 1,000 x 50 ftx oriented in the west-east direction. The pier consists of four steel barge units, each with overall dimensions of 250 x 50 x 10 ft., aligned end to end.

Coatings & Corrosion Control: Microbiologically Influenced Corrosion (MIC)

Recently, the use of certain environmental-friendly waxes or "semi-hard coatings", used by barge fabricators to protect the internal void walls and floors of marine double-hulled steel barges from corrosion, have fallen under scrutiny by some barge owners/operators. It is believed that certain paraffin wax coatings act as a food source for certain living corrosive microorganisms. These single-celled organisms are associated with a phenomenon known as Microbiologically Influenced Corrosion (MIC) that can cause localized pitting and eventually leaks in steel barge voids. This following examines the biological and chemical research that has recently been performed on the Jotun Paints, Inc, "beeswax" coating by two independent laboratories.

New Bridge Control Computer Onboard U.S. Navy Vessels

Azonix Corp.'s ProPanel line of industrial computers is being installed aboard CVN 68-USS Nimitz. In association with Henschel Corp. and Newport News Shipbuilding, ProPanel will be used to replace dial and gauge systems used in such critical applications as remote control of flight deck firefighting equipment and monitoring of navigation, ship control and meteorology systems. In engineering trials required for qualification in the Navy's COTS (commerical off-the-shelf) program, ProPanel was subjected to extremes of shock, electromagnetic radiation and humidity. Trials included the U.S. Navy's barge test, where depth charges were detonated under a 20 x 60 ft. steel barge, holding panel- and wall-mounted ProPanels.