Med Marine Delivers New Tug to Kenya Port Authority

Kenya Port Authority's new tug, Mwokozi II, was delivered to her home port of Mombasa on January 10, 2022.The Mwokozi II is a custom design 42-meter, 120 tonne bollard pull RAstar 4200 salvage and harbor tug developed by Robert Allan Ltd., with particularly outstanding performance in maneuvering, seakeeping, and stability.The Turkish shipbuilder Med Marine was contracted to build the new tugboat at its group owned Eregli Shipyard. The keel was laid on March 23, 2020, and construction…

First RAstar 2800-CL ASD Escort Tug Delivered

Svitzer Suez 1, the first RAstar 2800-CL ASD escort tug, has been delivered to Svitzer Egypt LLC by Cheoy Lee Shipyards and will soon commence operations in the Suez Canal. Svitzer are the first owners of this new escort tug design and a further nine tugs to this design have already been ordered with Cheoy Lee.The RAstar 2800-CL design started with a “blank sheet of paper”, according to naval architecture firm Robert Allan Ltd., who said one of the primary goals of the design was to make it extremely flexible allowing for various propulsion machinery options…

MacGregor Builds 1st Offshore Fiber Rope Crane

MacGregor, part of Cargotec, has completed the construction of FibreTrac, the first fibre-rope offshore crane to enter the market.The FibreTrac crane has a 150-tonne safe working load (SWL) capacity. It features a rope monitoring and management system that maximises rope lifespan and provides clear lift line status information for the operator at all times. It is designed to comply with DNV GL regulations."The project to build, certify and validate the MacGregor FibreTrac crane is the result of our confidence in its potential," says Høye Høyesen, Vice President, Advanced Offshore Solutions, MacGregor.FibreTrac uses existing, proven technologies…

U.S. Coast Guard Looks beyond Mooring Lines

Strength, Safety and Sustainability are at the heart of this Homeland Security stakeholder’s mission set.For over 30 years, high performance fiber rope manufacturer Phillystran has worked with the U.S. Coast Guard to supply mooring and towing lines. As innovations in fiber rope technology have enabled lighter and stronger ropes, the Coast Guard has not been slow to take advantage of these and other developments.In step with most maritime stakeholders, NAVSEA approved fiber ropes are widely used by the U.S. Coast Guard.

Tug Pair Delivered to PSA Marine

In August 2018, PSA Marine Singapore took delivery of two new 32-meter tugs, PSA Thor and PSA Hulk, built at PaxOcean Engineering Zhuhai Co., Ltd.The evolved RAmparts 3200 ASD hull form has been developed by Robert Allan Ltd. to provide ship assist in the berthing and un-berthing operations in ports/terminals and also coastal towing operations. Tugs of this design are capable of escort service as well. PSA Thor and PSA Hulk feature a uniquely styled deckhouse and wheelhouse developed exclusively for PSA Marine.The two new tugs join to PSA Marine’s existing fleet…

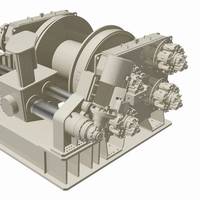

Markey ARR Winch System: Tried & Tested in the Toughest Tug Challenges

For more than 30 years, Markey Machinery has worked with the LNG and marine transportation Industries with the goal of developing winches designed to work under the most challenging conditions. The effort includes extensive design shop testing and actual commercial work, a combination that has ultimately produced an understanding of the operational issues facing terminal and tug operators. The many milestones in the development of Markey’s Asymmetrical Render/Recover (ARR) – technology by which hawser winches are able to maintain mean line pulls up to the bollard pull of the tug – came over a period of time that spans 25 years. The initial 20+ years of hawser winch design and Render/Recover development followed a traditional design path, influenced, in part, by market pressures.

Shaver Transportation Selects Rapp Marine Winch Package

Shaver Transportation of Portland, OR, operating vessels within the Columbia River region of the Pacific Northwest for over a hundred years, has selected Rapp Marine as the supplier of the two heavy-duty load handling winches on their latest tugboat. Rapp Marine has almost two decades of experience of designing and delivering rugged winches for workboat market, and has been around as a company for over a hundred years as well. The latest tugboat to the Shaver Transportation fleet is designed by Jensen Maritime of Seattle, WA and is under construction at Diversified Marine of Portland, OR.

Baydelta Chooses Rapp Marine Electric Tow Winch

For several decades, Rapp Marine has designed and delivered towing winches for workboat market. Combining the best ideas from Rapp’s past work in the other commercial industries and recommendations from the tugboat operators, Rapp Marine has developed long lasting and dependable towing winches. These past towing winches have mainly been powered using hydraulic systems in the North American market. Rapp Marine has previously delivered electric winches to commercial vessels in other industries such as research, oil & gas, and fisheries for years.

Dual-fuel Escort Tug for Østensjø Rederi

The first of three new dual fuel RAstar 4000-DF class extreme escort tugs, the Dux, has been delivered to Østensjø Rederi AS by Spanish shipbuilder Astilleros Gondán S.A. Designed by Robert Allan Ltd., the 40.2 meter vessel is the first of a three boat order from Østensjø for severe weather operations at Statoil's Melkøya LNG Gas terminal at Hammerfest in the extreme north of Norway. These escort tugs will conduct approximately 300 LNG ship escorts annually, assist with berthing operations and will be maintained in readiness for emergency services such as long line towing…

Rapp Marine Deck Equipment Rounds out New Harley Barges

Rapp’s workboat market offerings span the full range of operator requirements. Their latest contract provides a turnkey package. Long known for delivering innovative and custom deck machinery solutions to a wide range of marine stakeholders, Rapp Marine recently was tasked with providing not one, but two complete equipment package for West coast-based Harley Marine Services (HMS). The Rapp portfolio spans the full gamut of machinery, from heavy duty tow winches for high horsepower tugboats, all the way to multipurpose cranes for barges or other workboats.

Innovative Subsea Crane Ordered for RSV Conversion

Brazilian ship owning company CBO’s vessel CBO Manoella is currently being retrofitted from an offshore platform supply vessel (PSV) into a ROV Support Vessel (RSV). As part of the conversion project, CBO has assigned Rolls-Royce to equip the vessel with a new patented hybrid dual draglink (DDC) subsea crane, marking the first installation of a subsea crane designed to be able to use either fiber or steel wire rope. Marcelo Martins, CBO, Technical Director said, “This is one of two vessels CBO is now retrofitting from PSVs to RSVs…

Vessel Spotlight: RV Meen Shandhani

IMC’s latest fisheries research and survey vessel design was built in Malaysia for the Bangladesh Department of Fisheries. RV Meen Shandhani arrived in Bangladesh in June after completing extensive sea and fishing trials and its delivery voyage. The Australian consultancy’s naval architects and engineers drew on a wealth of relevant experience, data and expertise when developing the research vessel’s design. Formed in 1994, IMC and its principals have a long interest in, and association with, the fisheries sector.

Fiber-rope Retrofit Extends Subsea Crane Capabilities

MacGregor, part of Cargotec, has launched a fiber-rope retrofit option for its subsea cranes; the modular upgrade replaces the crane's original steel wire rope with synthetic fiber rope, using the same technology as MacGregor’s fiber-rope crane, the FiberTrac 1500, introduced earlier this year. These cranes combine MacGregor's offshore crane technology with the fiber-rope tensioning technology perfected by Parkburn Precision Handling Systems. According to MacGregor, fiber rope’s advantage when used in this context is that it weighs virtually nothing in water, so regardless of the length of rope paid out; it does not add anything to the load experienced by the crane.

IMCA Publishes Revision to Wire Rope Integrity Management Guidance

The International Marine Contractors Association (IMCA) has published a revised version of ‘Guidance on wire rope integrity management for vessels in the offshore industry’ (IMCA SEL 022 Rev. 2/IMCA M 194 Rev. 2). This is now available for downloading free of charge from the IMCA website. This document provides guidance on the necessary elements of an integrity management system required to achieve an acceptable level of ongoing safety for the use of wire ropes in a marine environment.

DNV GL Issues RP on Offshore Fiber Ropes

The results of two DNV GL led joint industry projects (JIPs) and a JIP pre-study commissioned by Statoil are now captured in a new Recommended Practice (RP) on offshore fiber ropes. With a system perspective on mooring performance, DNVGL-RP-E305 provides new industry guidance for achieving cost reductions of overall mooring operations, by addressing the engineering, manufacture and integration of offshore fiber ropes. The offshore oil and gas industry uses synthetic fiber ropes across various mission-critical activities where performance and reliability are key concerns.

Lifting Costa Concordia

The largest and most complex maritime salvage operation ever carried out was concluded this summer. The Costa Concordia parbuckling operation on the rocks of the Italian island of Giglio has been a success in many ways—not least for the objective to retrieve in one piece, such a massive vessel (117,000 tons) with minimal damage to the delicate marine environment on which it foundered. High performance ropes with Dyneema played a key role in the operation. DSM Dyneema has been supplying UHMWPE fiber, branded as Dyneema for ropes used in tug and salvage operations for almost 15 years.

Rope & Wires: At the Forefront of Technology

It hasn’t been too long since industry icon Tom Crowley, Jr. offered that the one technology that had the biggest impact on the safety and efficiency of [his company’s] maritime operations was, in a word: ROPE. The reasoning was simple. Today’s lighter, stronger synthetic strands have gone a long way in helping to reduce back and other related lifting injuries on deck. He stands by that answer today. So does Teufelberger, especially when it comes to the innovative products that they bring to the waterfront today. Established as a premium cordage manufacturer more than 220 years ago, Teufelberger produces products across its three distinct business divisions at its six locations around the globe.

Safety the Focus as Heavy Lifting Picks Up

Heavy lift operations offshore are an awe-inspiring feat, but an operation that requires consistent monitoring of man, machine and procedure to ensure they are conducted in as an efficient and safe manner as possible. Due to a growing focus on safety related to subsea lifting operations, DNV GL recently established a Joint Industry Project (JIP) to develop practical methods for reducing the risks and lifetime cost of steel wire ropes for subsea lifting applications, using an integrated systems approach.

DNV Helps Take the Strain on Subsea Lifting SWRs

Due to a growing focus on safety related to subsea lifting operations, DNV GL informs it has established a Joint Industry Project (JIP) to develop practical methods for reducing the risks and lifetime cost of steel wire ropes for subsea lifting applications, using an integrated systems approach. 14 diverse industry players have already signed up and more partners are welcomed, especially oil and gas operators, says project manager, Inger-Lise Tangen at DNV GL. Elisabeth Tørstad…

Wire Rope Integrity Regulatory Update

Current state-of-the-art wire ropes, updated regulation references, and flow diagrams to assist with the wire rope integrity management process have been included in the revised ‘Guidance on Wire Rope Integrity Management for Vessels in the Offshore Industry’ just published by the International Marine Contractors Association (IMCA SEL 022 Rev.1/ IMCA M 194 Rev. 1). “This document offers guidance on the necessary elements of an integrity management system required to achieve an acceptable level of ongoing safety for the use of wire ropes in a marine environment…

Delta Named Redaelli Exclusive Distributor

Delta Rigging & Tools, Inc., a provider of of lifting and rigging products and related services in the United States, announced that they have reached an agreement with Redaelli to be the exclusive Redaelli distributor for both onshore and offshore in the U. S. Gulf of Mexico region. The agreement gives Delta Rigging & Tools sales and marketing exclusivity in the Gulf of Mexico region for Redaelli specialty compacted, non-rotating and multi-strand Steel Wire Ropes. Based in Milan, Italy, Redaelli produces steel wire ropes leveraging almost 200 years of experience. Redaelli wire ropes are found in numerous onshore and offshore sectors.

LNG Mooring Lines Made with Dyneema

The introduction of new and larger vessels, Q-Flex and Q-Max, and new, often more exposed terminals becoming operational have changed mooring dynamics. The need to maintain workers’ safety at all times, whilst delivering maximum operational efficiency through lower costs and faster turnaround times remains unchanged. DSM Dyneema, a close partner to the LNG industry, has done a study which concludes that these industry trends are changing the performance demands for LNG mooring lines. In parallel to DSM Dyneema’s investigation, in 2011 members of the LNG community created a Users Group to further investigate HMPE mooring line failures which TTI (UK) was asked to facilitate. DSM Dyneema is part of the Users Group, while at the same time continuing its own investigation program.

Chinese Shipyards Wade In to Offshore Market

The recent Offshore Support Vessel World Forum meeting in Shanghai believes that optimism is returning to global offshore markets. The forum is a platform for oil and gas producers, designers, builders, OSV owners, operators, contractors, classification societies, equipment suppliers and legal/financial service units to discuss and address future opportunities and challenges. The theme of the conference was 'Maximizing commercial opportunities amid OSV market recovery by meeting new technical challenges and regulations'.