GE unveils GE Marine organization to power, propel and position the global marine industry

GE unveiled today its new GE Marine organization which cumulates several GE businesses and will be led by Tim Schweikert, vice president, GE Marine.

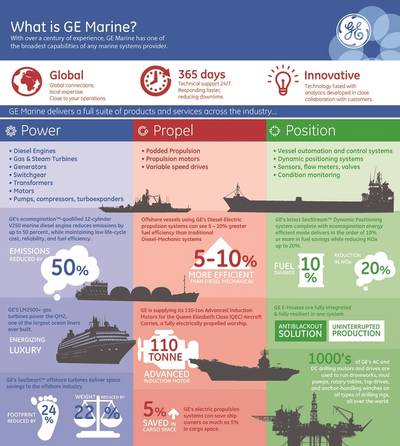

The new organization brings together GE’s commercial and technological expertise in the marine sector from gas turbines and diesel engines to motors and generators, variable speed drives and drilling systems to automation and control systems and all the electrical equipment in between. GE Marine combines this with system integration capabilities and a global infrastructure—including training and service facilities.

“It’s the breadth and depth of experience we are bringing together, imagining new solutions to emerging industry challenges and adapting world-class technologies from GE’s industrial portfolio that will give GE Marine an added edge to consistently bring our customers the best marine solutions,” said Schweikert. “GE offers highly advanced technology that enables our customers to operate in some of the world’s harshest environments.”

GE Marine builds on the foundations laid out by the GE Global Offshore Marine organization established in 2013 to provide integrated solutions to GE’s offshore customers. Evolving with the industry and its customer needs, GE Marine puts more than marine experts at their service.

“Today’s announcement reflects how GE’s focus is on growing its marine business around strong technology platforms,” said Joe Mastrangelo, CEO, GE’s Power Conversion business. “Our customers will benefit from a highly integrated, technologically rich solution for a wide range of marine applications. From the most advanced frigates to the largest luxury cruise liners to the hardest-working FPSOs, we power, propel and position the marine industry.”

GE said it also is building the Industrial Internet for its customers. The deeper meshing of the digital world with that of the marine industry provides the potential to bring about profound industry transformation, most notably in the areas of predictability, shipbuilding and marine propulsion. These innovations promise to provide increased availability and greater efficiency for GE Marine customers.

“By creating a one-stop shop for our marine customers, we are better positioned to help them succeed in an increasingly competitive world. This new organization will leverage expertise and technology from across GE’s global businesses, expand our capabilities and provide solutions that will lower operating costs and make the next generation of ships more efficient and environmentally friendly,” said John Rice, Vice Chairman, GE.

Latest industry news from GE Marine

-Kawasaki Heavy Industries (KHI), Ltd. has ordered electric power and propulsion systems for two LNG carriers. The LNG carriers will be built to transport LNG from Louisiana, USA. Their construction is scheduled to be completed between 2017 and 2018.

From the perspective of improved performance, electric propulsion technology is optimal for LNG carriers. GE's robust, simple induction-based propulsion motor technology and high-output power pulse width modulation (PWM) technology improve reliability and help lower maintenance costs for vessels.

"GE has demonstrated a low-risk solution to KHI, showing professionalism in the execution plan and a high standard of quality control of their equipment, which is the result of extensive experience in the supply of 65 Dual Fuel Diesel Electric (DFDE) drive systems with induction technology for LNG carriers over the last decade. GE is happy to forge this new partnership with a key player in the marine industry showing its future commitment to Japanese customers," said Paul English, marine business leader, GE's Power Conversion business.

The technology that Power Conversion has introduced to the maritime industry comes with an extensive track record and is currently used broadly for military, offshore vessels and cruise ships, which require optimum performance and power output in the several megawatt classes for electric power and propulsion efficiency.

-Harvey Gulf recently purchased two of GE Marine's new EPA Tier 4 emissions-compliant medium-speed diesel engines for its latest multi-purpose field support vessel. Harvey Gulf provides offshore supply and multi-purpose support vessels for deep-water operations in the U.S. Gulf of Mexico. Harvey Gulf will be among the first customers to operate GE's diesel engines that meet EPA Tier 4 emissions standards without SCR after-treatment or urea injection.

"We chose the GE Marine Tier 4 engines for their reliability, low life-cycle cost, capability to meet EPA Tier 4 emissions requirements without urea after treatment, weight and space efficiency as well as ease of maintenance," said Shane Guidry, chairman & CEO of Harvey Gulf.

-GE Marine will provide dynamic positioning (DP) and vessel control systems to equip the next-generation platform supply vessels, currently under construction at the Detroit shipyard to the Brazilian shipbuilder Starnav Serviços Marítimos Ltda. These vessels, the first of which will be commissioned and will be put into operation by Starnav in 2015, will target fuel efficiencies as one of its primary aims.

"As the industry faces ever more stringent cost-competiveness, vessels need to perform efficiently with optimized fuel consumption and reduced environmental footprint. GE's Power Conversion business excels in offering such technologies that meet both requirements," said Carlos Eduardo Pereira, general director, Starnav Serviços Marítimos Ltda. "GE's technology also helps to enhance the overall competitiveness when we are seeking prized charters from major operators thanks to additional factors such as reliability. We are proud to have this long-term partnership with GE."