Polymers Avert Pollution Threat

Among the more compelling news photos published following the landfall of Hurricane Sandy was that of the 184' tanker John B. Caddell run aground onto a Staten Island street by tidal flooding.

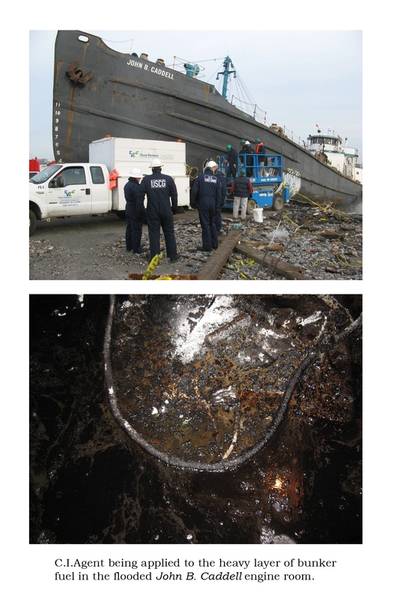

That the tanker required heavy lifting to return it to sea was only part of the problem. A layer of bunker fuel shrouded the vessel's flooded engine room, creating a contaminated work area. C.I.Agent Solutions assisted with remediation so salvage work could move forward.

C.I.Agent Solutions' solidifying polymer granules and EVAC Filtration System were used to help clean the contaminated engine room. C.I.Agent, the company's key product, is a proprietary and environmentally friendly blend of seven polymers. It encapsulates and solidifies dangerous hydrocarbon spills on contact. The resulting non-toxic and non-leaching rubber-like mass enables easy removal.

The tanker's remediation project was directed by the USCG Atlantic Strike Force along with environmental contractor Clean Venture, Inc. Much of the water in the engine room was pumped into two 20,000-gal. frac tanks, leaving behind a heavy, oily sheen. C.I.Agent polymer was then broadcast into the lower engine room to solidify the surface oil. The process was assisted by a small submersible pump, which agitated the water to further expose the oil to C.I.Agent.

Responders then removed the solidified oil with pool skimmers.

C.I.Agent Solutions' EVAC Filtration System permitted the safe decanting of oily water in the frac tanks. The filter is comprised of non-woven geotextiles that are hydrophobic and adsorb hydrocarbons, plus a 6" x 6" C.I.Agent Hydrocarbon Solidifier Pillow. The EVAC's state-of-the-art filtration technology removes suspended solids, sediment and light sheen. It also polishes the water.

All told, the tanker cleanup required eight 10-lb. pails of C.I.Agent polymer granules and two EVAC Filtration Systems. Approximately 50 lbs. of solidified oil—roughly seven gallons—was removed from the engine room.

The use of C.I.Agent polymers on the John B. Caddell engine room permitted a much faster resolution than if a traditional oil spill cleanup method such as a vacuum truck or skimmer had been chosen. Another advantage of cleaning with a polymer such as C.I.Agent is that the solidified oil requires no special processing afterwards. It can be recycled or reused in many industrial applications, and is safe for landfill disposal.

"This operation was a success," said Mike Gallagher, marine rep for C.I.Agent Solutions. "It is rewarding for our company to know we helped prevent damage to the environment, and were able to demonstrate the effectiveness of our products."