USCG Implements Handheld Technology for Onboard Oil Testing

With a motto of Always Ready, the United States Coast Guard (USCG) has 11 missions specified by law including drug and migrant interdiction; ports, waterways and coastal security; fishery patrols; search and rescue; and national defense. The USCG’s newest ships including 22 Fast Response Cutters (FRCs) recently entered service with 36 more on order and six new National Security Cutters (NSCs) with two more in the process of being built. Oil analysis plays a critical role in the mission readiness of these new cutters by alerting cutter engineers to problems that have the potential to damage vital equipment and by helping them efficiently deploy scarce resources to critical maintenance activities.

The traditional approach for oil analysis is to ship samples to a central lab, which requires days before results are received. On the FRCs and NSCs, the USCG has implemented the use of handheld oil analyzers to monitor regularly lubricant condition on diesel engines and other vital equipment. “The new onboard analyzers are used to detect oil quality issues and prevent potential damage to equipment, avoid unnecessary oil changes and perform oil changes based on actual condition,” said Edgardo Guevara, Lubrication Program Manager for the USCG. “An abnormal condition detected by the onboard analyzer alerts the engineers to perform corrective action and submit the oil sample to our contracted oil lab for complete oil and wear analysis.

Onboard oil analysis used on new cutters

Named after Coast Guard enlisted heroes, the 154-foot-long FRCs are replacing the aging Island-class patrol boats. The FRCs feature advanced command, control, communications, computers, intelligence, surveillance and reconnaissance equipment; over the horizon cutter boat deployment to reach vessels of interest; and improved habitability and seakeeping. The 418-foot-long NSCs address the need for open-ocean patrol cutters with the seakeeping, habitability, endurance and technological advancements necessary to serve as command and control centers in the most demanding maritime environments. Onboard oil analysis also is used on two polar icebreakers.

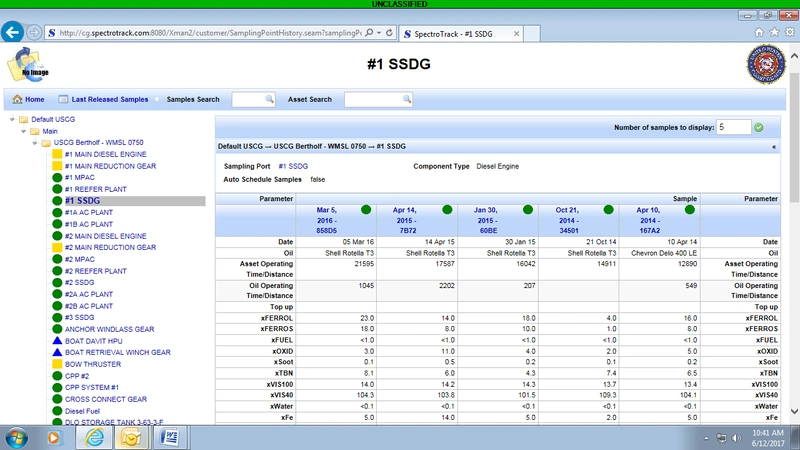

Prior to 2012, USCG had no centralized oil laboratory testing and analysis program. Cutters sent oil samples to the Navy Oil Analysis Program (NOAP) or Joint Oil Analysis Program (JOAP) labs, engine manufacturer labs and other local commercial labs. “It typically took weeks after the samples were taken to get results, often too late for cutter engineers to take corrective action,” Guevara said. “There were no standardized testing requirements for different components and the test results remained at the different laboratories where the oil testing was performed. Some reports did not provide analysis or recommendations. Onboard oil testing was limited to viscosity testing on main diesel engines using falling ball viscometers. Most cutters perform engine oil changes based on time schedules ranging from every 500 to 1000 hours on main engines and 250 to 500 hours on ship service diesel generators (SSDGs).”

Selecting and validating onboard analyzers

At about the time Guevara joined the USCG in 2011, the engine manufacturer for the FRCs stated that a shipboard testing unit was required to monitor the oil in the main engines. Also, the NSCs require a shipboard test unit to monitor the oil in the main engines. “The Project Office was considering the use of traditional one-test-at-a-time kits that rely on chemicals and reagents to perform oil analysis,” Guevara said. “I was concerned about the amount of time required to perform the tests and the potential for inaccurate results because they are dependent on using the right amount of oil and chemicals and the condition of the test kit. I recommended the Spectro FluidScan handheld monitor and MiniVisc 3000 portable viscometer as a better alternative because they provide results in much less time than chemical kits and deliver consistent results comparable to central labs without being sensitive to the skill of the operator. The Project Office followed my recommendation and implemented the use of the FluidScan and MiniVisc 3000 combo onboard the FRCs. In 2012, three NSCs were already using the test equipment that uses chemicals and test reagents for shipboard testing and after a successful trial test of the FluidScan and MiniVisc 3000 combo unit onboard one of the NSCs, the product line manager approved the switch to the combo unit.”

The FluidScan is a rugged, handheld infrared spectrometer that measures a range of key oil condition parameters including total acid number (TAN), total base number (TBN), oxidation, nitration, sulfation, additive depletion, incorrect lubricant, water, glycol, soot, glycerin and FAME in biodiesels in synthetic and petroleum-based lubricants and fluids. The portable monitor provides reproducibility and repeatability comparable to a benchtop Fourier transform infrared spectroscopy (FTIR) method ASTM E2412. The MiniVisc 3000 is an easy-to-use portable, battery-operated instrument that determines kinematic viscosity in the field without the need for solvents, density checks nor a thermometer. The split cell design provides accuracy +/- 3 percent standard deviation to National Institute of Standards and Technology (NIST) viscosity standards.

Guevara validated that the FluidScan and MiniVisc 3000 instruments could meet the technical requirements for shipboard use as specified in the USCG Technical Standard 262 – Lubricating Oils and Systems, Testing and Analysis. He created a protocol for engineers on the two new cutter classes to test vital equipment on a regular basis. The FluidScan is also used on an as-needed basis as a troubleshooting device to monitor water contamination in other lubricating oils.

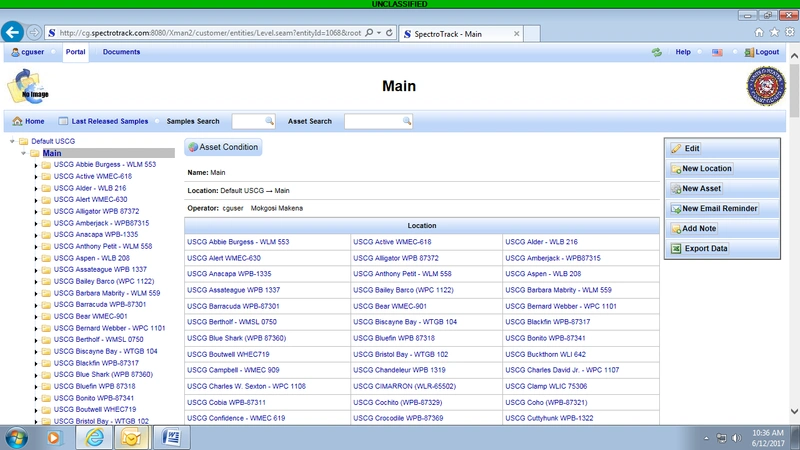

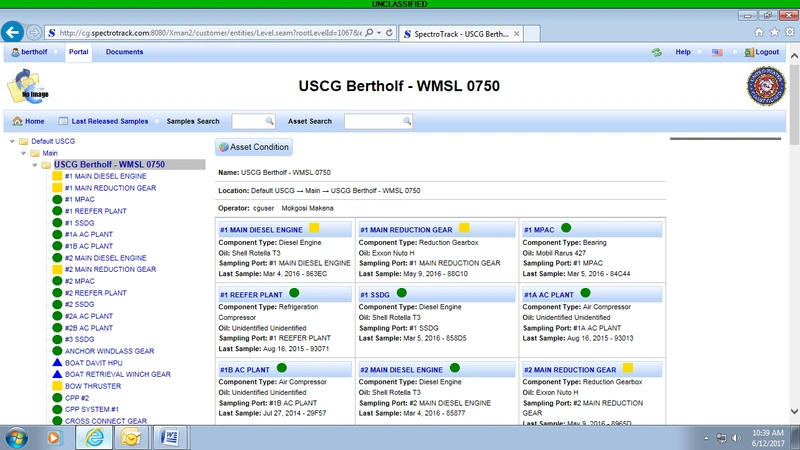

Guevara recognized the need for the USCG to maintain full control of its oil analysis data from the centralized lab and the cutters’ onboard analyzers through a web-based database. After two years of research, he selected the SpectroTrack IMS (information management system) software as the database to archive this data. Engineers will be able to view the results on a browser and make decisions such as when to perform oil changes and other maintenance activities based on the actual condition of oil and equipment.

The approval process for the SpectroTrack IMS software began in November 2014 and has completed the post-validation phase. The USCG’s goal in the near future is to have the capability to upload the test data from the FluidScan unit to the SpectroTrack database by the cutter using the units. The SpectroTrack database holds about 13,000 sample test results from the centralized laboratory to date. The database is not currently being implemented for fleet wide use until it has obtained USCG CROP approval.

Improved mission readiness and cost savings

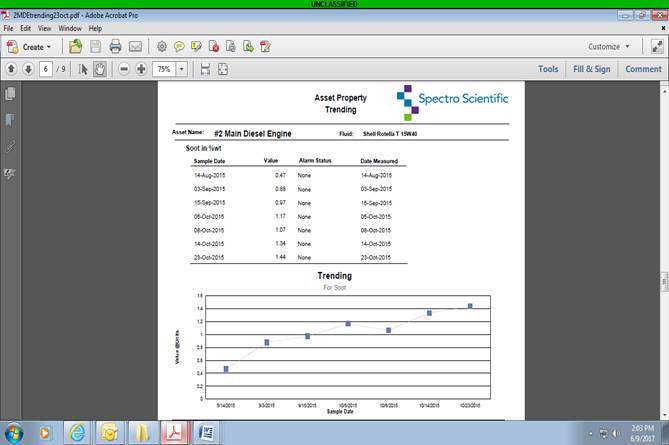

“Through the centralized oil testing program and use of onboard analyzers, USCG now has complete ownership and visibility of all test data for the first time,” Guevara said. “We have full confidence in our data which makes it possible to make decisions that improve our mission readiness and save money on unnecessary oil changes and maintenance. In several cases, onboard analyzers have identified potential problems so they could be corrected before equipment was damaged, which would have required expensive repairs and potentially put the cutters out of action. Using the FluidScan and MiniVisc 3000 combo units, engineers onboard the NSCs can closely monitor increasing soot content in the engine oil as it moves towards the limit where an oil change is required. The FluidScan is also used as a troubleshooting device to monitor water ingression in the reduction gears.”

Guevara said the cost savings associated with onboard oil analysis have also been substantial. “We found that by monitoring the condition of the oil on the NSC main engines, we were able to increase the oil change interval from 500 hours to 1000 hours based on actual oil conditions, eliminating two oil changes per engine per year, which will save each cutter about $10,000 per year in oil change and disposal costs and also reduce downtime. We are now reviewing our oil change policy on the FRCs ship service diesel generators (SSDG) to extend the interval from 250 hours to 500 hours or as oil analysis results dictates.”