ERMA FIRST BWTS Receives AMS Acceptance from USCG

ERMA FIRST S.A. is amongst the few companies that have already received the acceptance letter from USCG. ERMA FIRST BWTS received its AMS Acceptance letter on October 11. The ERMA FIRST BWTS is compatible with global legislations and conventions, international requirements and restrictions. AMS approval is one more reward and ascertainment that ERMA FIRST BWTS has completed with success all technical challenges.

AMS approval has been given to ERMA FIRST S.A. for its following models: BWTS 50, BWTS 100, BWTS 200, BWTS 300, BWTS 400, BWTS 500, BWTS 600, BWTS 700, BWTS 800, BWTS 900, BWTS 1000, BWTS 1100, BWTS 1200, BWTS 1300, BWTS 1400, BWTS 1500, BWTS 1600, BWTS 1700, BWTS 1800, BWTS 1900, BWTS 2000, BWTS 2100, BWTS 2200, BWTS 2300, BWTS 2400, BWTS 2500, BWTS 2600, BWTS 2700, BWTS 2800, BWTS 2900, BWTS 3000 and associated filter housings, as type approved by the Hellenic Republic, Ministry of Development, Competitiveness & Shipping, Merchant Ships Inspection General Directorate, design and Construction Directorate number 4245.9/01/12 issued 10 May 2012.

The ERMA FIRST Ballast Water Treatment Systems are assigned the AMS identification number AMS-2013-ERMA FIRST Ballast Water Treatment System-001.

The ERMA FIRST BWTS had provided all methods and results during land and shipboard testing in accordance with U.S. Standards.

So far, the most challenging water conditions such as natural richness and density of organisms, high particle and sediment load, were performed at NIOZ facilities with high fidelity and the results were successful.

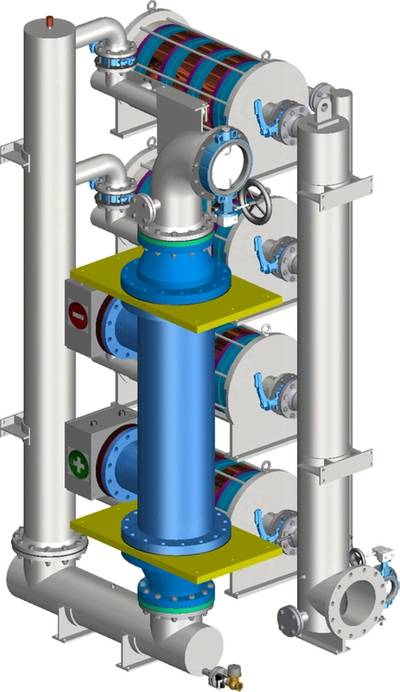

ERMA FIRST BWTS is an electrolytic system which incorporates an advanced separation stage based on hydrocyclones. The separation stage of the system is a unique method of stable operation, achieving extreme sediment removal, while warranties no clogging risk. Its excellent design offers to the user minimal maintenance costs since it is consisted of no moving parts and thus requires no spare parts. The system has been designed to offer low energy consumption in order to reduce environmental impact. It has been carefully formed for easy installment.