New Forming Machine for the Construction Site

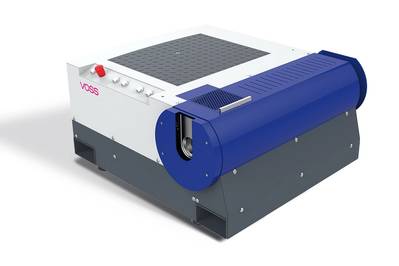

Sometimes less is more. That’s also true for the size and weight of pre-assembly devices that are predominantly used at construction sites. They need to have compact designs but nevertheless work precisely, fast and safe, just like the new VOSSForm 100 Compact forming machine.

The mobile bench machine shapes a contour on hydraulic tubes. In combination with a soft seal and function nuts, this results in extremely leakproof and process-reliable tube connections. The solution is ideal for steel and stainless steel tubes in the range from six to 42 mm outside tube diameter.

Wherever especially safe and leak-free tube connections are important during repairs, maintenance and service, the mobile forming machine from VOSS Fluid demonstrates its inherent advantages. The size and weight is designed for shipping in a transporter; a mount for a forklift and additional lifting rings provide the unit with the mobility required at the construction site. That meets all requirements to make especially secure tube couplings using forming, even in mobile assembly service. The system package is very straightforward: The forming machine shapes a 24-degree tube contour at the end of a hydraulic tube. This is supplemented with a soft seal and a function nut that is equipped with a special clamping ring. The result is an extremely high-quality and leakproof connection that is exceptionally resistant to high bend change stresses.

Forming process

Forming with the VOSSForm 100 Compact is extremely straightforward and self explanatory: The mechanic inserts the marked tool in the unit and pushes the tube end against the limit plate. During processing, the machine always displays the next operational step. Even the forming pressure setting is automatically controlled. The integrated tool is a negative mold of the contour you want to shape. That ensures that the contour is always executed to perfection - a decisive advantage of the forming machine. Insertion mistakes and operator errors are as good as ruled out, which leads to fast and precise results and effectively prevent scrap. The forming power of the machine is about 100 tons and is designed as a service unit for smallest-lot production. For series production, VOSS Fluid recommends the big brother of the bench machine, the stationary VOSSForm 100 floor-mounted appliance with integrated oil cooling and tool magazine.