Bore, NAPA & ClassNK Team for Energy Consumption Study

Saving energy on fleet operations is a top line concern for every vessel owner, large and small. 110-year-old Finnish shipowner Bore teamed with NAPA and ClassNK to help identify energy waste on not only its ships operating today, but those planned for tomorrow.

As global environmental legislative mandates and rapidly escalating fuel prices cumulatively conspire to drive ship owners to find and eliminate energy waste on commercial marine vessels, there has been a plethora of energy saving solutions from all sectors of the industry. But while “solutions” are plentiful, concrete proof tying cause and energy savings effect is more scarce.

That is a factor which drove Bore, a Finnish ship owner with 18 vessels (RoRo and General cargo) and 110 years of experience to team with NAPA and ClassNK recently for an onboard trial of the new ClassNK-NAPA GREEN ship efficiency software to help identify, in real time, specific areas where its ship was wasting energy.

“We wanted to be sure to identify exactly where the savings were coming from,” said Jörgen Mansnerus, VP, Marine Management, Bore Ltd., in a recent interview, explaining the company’s rationale to participate in the test. “We wanted hard data.”

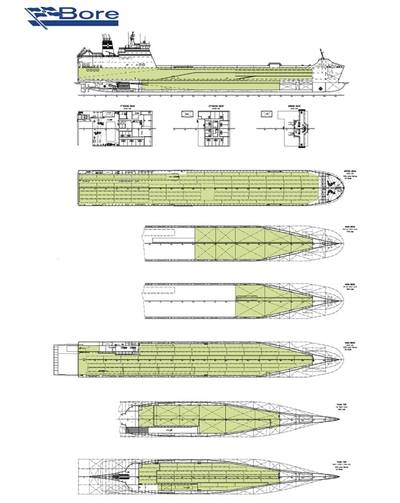

The Ship

Perhaps the most interesting part of the ClassNK-NAPA GREEN ship efficiency software trial with Bore was the fact that the owner specifically chose its newest, most efficient vessel for the trial. To provide the most challenging environment, the software was installed aboard the 13,625 dwt highly efficient RoRo vessel M/V Bore Sea, delivered in 2011 from Flensburger.

“We challenged NAPA last year to see if they could deliver further improvements on ships that are already new and efficient,” said Mansnerus.

M/V Bore Sea measures 195.4 x 26.2 m with a 7.4-m draft, powered by a single Wärtsilä 12V46F-CR 12,000 kW medium speed diesel engine, and classed by Lloyd’s Register. In addition the ship sports a pair of auxiliary diesel engines (1,270 kW); a pair of diesel driven generators (1,500 kVA); a shaft generator (3,750 kVA); and an emergency generator (410 kVA). M/V Bore Sea has a service speed 19 knots (at design draft of 7.05 m, 81% Load, shaft generator load 300 kW), a maximum cruising range of about 9,500 sea miles and a consumption of about 43 t/day. When the trial was completed and the smoke had cleared, the shipowner found that the operational software had led to a 5.8% reduction in fuel consumption, a big factor in it extending the installation of the ClassNK-NAPA GREEN ship efficiency software aboard the 13,625 dwt highly RoRo vessel M/V Bore Song. “Last year’s sea trial of operational software was a significant factor in our decision to choose ClassNK-NAPA GREEN,” said Mansnerus. “We are confident that this software is a wise investment that will begin to offer fuel savings aboard this vessel from installation, and proud that we are able to offer this efficiency and lowered fuel spend to the charterers who will be reaping the benefits.” And while the savings were impressive, the insight it provided was even more so. “With the Class NK / NAPA Green system you can accurately identify the areas where you are wasting energy, where before you had to guess,” said Mansnerus.

The Software

“This system provides an opportunity for the shipbuilder to understand how a ship operates efficiently in real world conditions. Once they know, they can improve their design to enhance the efficiency of the ships,” said Yasushi Nakamura, Executive Vice President, ClassNK. The ClassNK-NAPA GREEN software system is a joint development between Nippon Kaiji Kyokai (ClassNK), the world’s largest ship classification society, and NAPA, a company which offers software both for the design of ships as well as the operation of ships. In fact, it is this unique combination, according to Juha Heikinheimo, President, Napa Group, that makes NAPA stand out amongst a growing sea of software solution providers.

“Napa has the possibility now, with ClassNK to develop a dynamic performance model, developing a 3D model of the ship according to the different sea states and conditions, in order to predict accurately the coming voyage,” Heikinheimo said. “Nobody provides a loading computer, with all of these operational devices, in real time, based on facts that you understand from the 3D model.”

He claims this is a powerful combination, both in terms of helping existing ships to save energy, but more so in incorporating the date into future, more fuel efficient design. Feedback from the ship’s real-world operational efficiency under a diversity of conditions can be fed back directly to the ship designer and builder, helping them to design and build ships based on real operational conditions and parameters, instead of designing for optimal conditions.

“It is not the fuel consumption savings, it is Normalized data based energy savings,” said Heikinheimo, “and we see proven 6% absolute energy savings.” The software solution was launched in 2012, and builds upon the shared experience of both organizations to provide a solution to reduce fuel spend and greenhouse gas emissions whilst also providing compliance with ship energy efficiency management plan (SEEMP) legislation. Bore has been working closely with NAPA around operational software for vessels for sometime.

“It is heartening to see the industry embracing the financial and environmental benefits that software systems such as ClassNK-NAPA GREEN offer,” said Nakamura. “We are aware of the increasing challenges being placed on shipping financially, environmentally and through increased regulation.”

In the trial with Bore, according to the shipowner, speed optimization (and by natural default extensive route planning which helped to cut down on speed fluctuation) was hands-down the biggest factor in saving energy. And while all of the partner were remiss to put a price tag and ROI on the solution, (in part because, regarding ROI, results are dependent on the age of the vessel and the route it serves) Mansnerus did concede that the return on investment was less than one year, and in the test case, closer to six or seven months.

(As published in the October 2013 edition of Maritime Reporter & Engineering News - www.marinelink.com)