Digitalization: From Stem to Stern, Ship Design in 3D Digital

3D digital design can save ‘dollars on the deck plate’ during construction while maintaining safety, says to Patrick Ryan, Senior Vice President, Global Engineering and Technology, ABS.

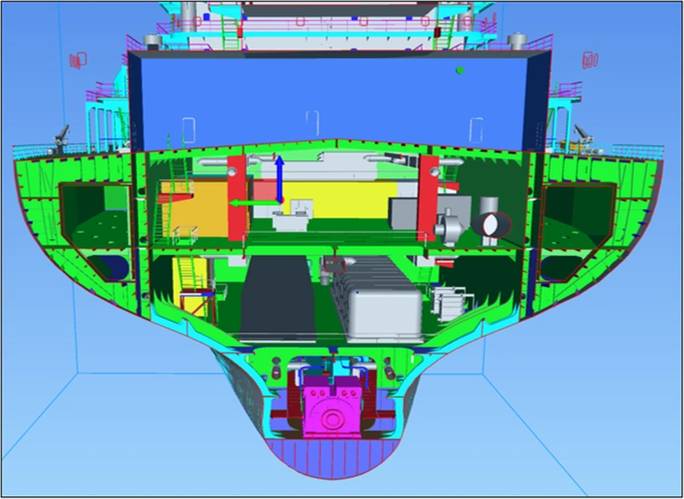

Last year ABS, Robert Allan, Signet and USCG collaborated on a project that would be the first commercial vessel in U.S. history to be produced using only 3D models in design and construction for all structures. While the process used to deliver this RAL-designed Advanced Rotortug (ART) is historic, it is just the start as Ryan contends that a purely 3D process reduces costs and time investment, while streamlining interaction between all stakeholders throughout the design, verification and construction phases, without compromising safety.

“ABS started focusing on this (pure digital process) in 2018 with a series of joint development R&D projects,” both publicly promoted as well as ones that have been kept private, said Ryan.

These early development projects were effectively building blocks in the digitalization production process, the ART tug representing the completed structure, “purely and completely, stem-to-stern, all drawings replaced with 3D CAD from a plan review standpoint.”

As is turns out, ABS has not simply been on the digital path, it has been on point helping to bring together disparate parties to effectively lead the transformation, with a keen eye not solely on efficiencies and cost savings, but increased levels of safety, too.

“To a large degree, it's really about enabling our clients to save dollars on the deck plate during construction while maintaining the class focus on safety,” said Ryan. While savings vary greatly depending on the scale of the project and are proprietary bits of information held closely, Ryan said the savings can be substantial. “I come from shipbuilding before my time with ABS, and I really think about this in the lean manufacturing perspective of the elimination of waste.”

“(I’ve been saying for more than a decade that) engineering drawings are a waste in the lean manufacturing sense because they are an inefficient communication method,” said Ryan. “With mobility and modern technology and the advent of computers on the deck plate, it makes that drawing production an antiquated process.”

“I took drafting in college and I have respect for the romance and the beauty of an engineering blueprint. But if you can communicate directly from the CAD to those downstream stakeholders and eliminate the drawing from the production process, you save money in engineering.”

The ABS way on 3D model integration

The milestone with RAL and Signet is just the latest in a succession of ABS firsts in 3D Model-based Class. According to the classification society, ABS was the first to develop a process for ingesting 3D models into class software to allow 3D model-based reviews in 2018. ABS then became the first classification organization to accept 3D models for class surveys in April 2020.

“We are very focused philosophically on being flexible, regardless of file format, regardless of pure CAD or PLM involvement, effectively making it easy for everyone,” said Ryan.

“ABS does not want to dictate to the shipyards what format or what file types they need to submit to us. We work with those yards, typically in a JDP first, to establish what that exchange process looks like and then we build upon their existing process to make it easy for them, rather than trying to drive the industry toward a standard.”

To the Cloud

Watching the 3D process evolve from R&D to the market has been an exciting one for Ryan and his team, and it’s brought along its share of surprises, too, particularly with its broad interest and acceptance. “What surprised me the most about this is this isn't a capital ship, this isn't a major vessel approach,” said Ryan. “I thought the early adoption in this would be in big capital projects that were driven by the high-tier shipyards for hundred-million-dollar projects. That's not been the case. We've seen this (interest) across the spectrum, (from) big ships, to patrol craft, to tugs, and all the way down to barges.”

Though still in its infancy, Ryan is looking ahead … or rather up … to ‘the cloud.’

“The exciting thing is that, starting last year really, we started moving it from an R&D project into the core process of ABS,” said Ryan. “We're starting to move all of this approach into the cloud to really facilitate that exchange and make everything easier. We know there are security questions, and we are attacking that with great rigor to make sure that that data is well protected. The future is bright for digital class exchange.”

- Watch the full interview with Patrick Ryan on Maritime Reporter TV: