LGP-Fuelled ME-LGIP to Power Chinese VLGC

Further shipowners turning to LGP in advance of 2020 emissions deadline

Jiangnan Shipyard, owned by China State Shipbuilding Corp (CSSC), has ordered an LPG-burning MAN B&W 6G60ME-LGIP engine in connection with the building of an 86,000-m3 VLGC (Very Large Gas Carrier) for Tianjin Southwest Maritime (TSM), the Chinese shipping company. Vessel delivery is scheduled for the second half of 2021 and includes an option for a second vessel.

Bjarne Foldager – Senior Vice President, Head of Two-Stroke Business at MAN Energy Solutions – said: “With 2020 and the new IMO emissions fast approaching, interest in using LPG as a fuel – within and outside of the LPG carrier segment – is growing due to its sulphur-free character, widespread availability, price competitivity, and ease of bunkering. At MAN Energy Solutions, we feel that the introduction of the ME-LGIP is proving timely.”

MAN Energy Solutions already won the first orders for the new engine earlier in 2018 when Hanjin Heavy Industries announced that it would construct 2 × VLGCs (Very Large Gas Carriers) in their Philippines Facilities for Exmar, the Belgian integrated gas-shipping company. The 86,000 m3 newbuildings will each be powered by an individual MAN B&W 6G60ME-LGIP Mk9.5 engine.

The company could also announce the first retrofit orders for the ME-LGIP in September 2018 when it signed a contract with Oslo-listed BW LPG for the world’s first retrofitting of four MAN B&W 6G60ME-C9.2 HFO-burning engines to 6G60ME-C9.5-LGIP LPG-propelled dual-fuel engines. The order includes options for further retrofits in the future with work expected to begin during 2020.

Foldager added: “In gas mode, the ME-LGIP engine operates on just 3% pilot oil and down to 10% load. Ultimately, we expect the engine to operate without the need for pilot oil. The ME-LGIP can also burn liquid volatile organic compounds, a deliberate move on our part since the IMO will inevitably turn its focus towards the reduction of volatile organic compounds in the future. Accordingly, we view the ME-LGIP as also ideally suited to the propulsion of shuttle tankers and very large crude carriers.”

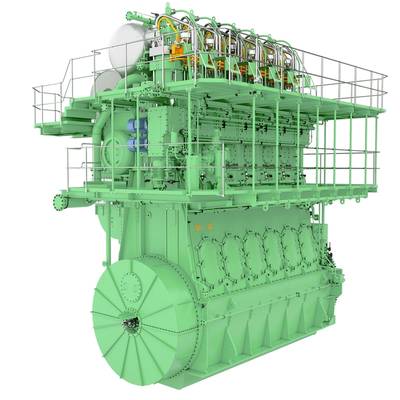

The MAN B&W ME-LGIP engine

MAN Energy Solutions revealed its latest two-stroke engine type at a ceremony in Copenhagen in September 2018. The ME-LGIP (-Liquid Gas Injection Propane) engine builds on the success the company has had with its ME-GI and ME-LGI dual-fuel engines, which have won over 250 orders since their introduction to the market. Employing essentially the same proven technology, LPG has now been added to the expanding list of non-HFO and alternative fuels that MAN Energy Solutions’ two-stroke technology can exploit.

The Diesel principle provides the ME-LGIP engine with high operational stability and efficiency, including during load changes and fuel change-over, while defining properties such as a stable change-over from one fuel type to another with no fuel-penalties are maintained. The negligible gas slip of the ME-LGIP engine makes it the most environmentally friendly, two-stroke technology available.

MAN Energy Solutions expects a strong demand for the ME-LGIP engine from very large gas carriers (VLGCs) and coastal vessels.

MAN Energy Solutions also reports that the ME-LGIP engine has experienced an up to 18% reduction in CO2 and circa 90% reduction in particulate matter when running on LPG, compared with HFO.

The Maritime Energy Transition

The development of the ME-LGIP engine to burn LPG is part of the ‘Maritime Energy Transition’, an umbrella term that covers all MAN Energy Solutions activities in regard to supporting a climate-neutral shipping industry.

The term stems from the German expression ‘Energiewende’ and encapsulates MAN Energy Solutions’ call to action to reduce emissions and establish natural gases as the fuels of choice in global shipping. It promotes a global ‘turn to gas’, driven by the IMO, and a common approach by the shipping industry and politics to invest in infrastructure development and retrofits.

Launched in 2016 after COP 21, the initiative has since found broad support within the shipping industry and politics.

LPG installation

With the ME-LGIP engine, LPG joins the list of liquid, environmentally-friendly fuels that can power MAN Energy Solutions’ portfolio of two-stroke, dual-fuel engines, which are available from all licensees. MAN Energy Solutions further reports that it expects ME-LGIP installation aboard merchant vessels to be extremely competitive price-wise, compared to other, dual-fuel-burning engine types.

LPG as fuel

Due to ever more stringent emission limits, many LPG carrier operators called for MAN Energy Solutions to develop an LPG-fueled engine that could power LPG carriers in the most viable, convenient and economical way using a fraction of the cargo already onboard.

LPG is an eminently environmentally-friendly fuel, in much the same class as liquefied natural gas (LNG), and an LPG-fueled engine will significantly reduce emissions, enabling vessels to meet the stringent IMO SOx emission regulations due to come into force globally from 2020. As well as being an important step towards reaching the 2050 IMO GHG targets, LPG also gives credit towards IMO EEDI compliance requirements.

LPG’s future as a viable fuel for general marine transportation looks promising as it will not require as large an investment in infrastructure – such as bunkering facilities – in contrast to other, gaseous fuels. As a widespread energy source, availability is high and LPG is easier to store and handle, compared with cryogenic gaseous fuels.

Furthermore, LPG is traditionally a cheaper fuel than MGO yet delivers the same performance and efficiency. Importantly, the ability to use LPG cargo as a supplemental fuel source provides significant cost savings for LPGC owners or charterers, including reduced time and fees for fuel bunkering. Accordingly, MAN Energy Solutions expects a strong demand for the ME-LGIP engine from very large gas carriers (VLGCs) and coastal vessels from its introduction.

The ME-LGI concept

With a new injection concept, initially developed for methanol, the ME-LGI concept greatly expands the company’s dual-fuel portfolio and enables the exploitation of more low-flash-point fuels such as ethanol, dimethyl ether and, now, LPG.

The engine’s ‘ME-’ prefix indicates that the new engine benefits from well-proven electronic controls that also encompass the fuel being injected by the so-called Fuel Booster Injection Valve. This innovative fuel booster, specially developed for the ME-LGI engine, ensures that a low-pressure fuel-gas supply system can be employed, significantly reducing first-time costs and increasing reliability.

The ME-LGI came about due to interest from the shipping world in operating on alternatives to HFO. Methanol and LPG carriers have already operated at sea for many years and many more LPG tankers are currently being built as the global LPG infrastructure grows. With a viable, convenient and comparatively cheap fuel already onboard, it makes sense to use a fraction of the cargo to power the vessel with an important, side-benefit being its positive, environmental performance.