MAN Releases First IMO Tier III Workboat Engine

551 to 1,213 kW engine power range now available; low-cost, SCR-only solution; technology in standard production at MAN since 2006.

MAN Engines – a business unit of MAN Truck & Bus – is now offering 12-cylinder, IMO Tier III emission standards engines for workboats, spanning a comprehensive power range from 551 to 1,213 kW. The engines are im-mediately available. This is particularly relevant to customers in Canada and the USA’s East and West Coast Emission Control Areas (ECAs), who are now subject to regulatory limits around 70% stricter than IMO Tier II. Customers in the North Sea and Baltic Sea ECAs needing to prepare for the mandatory limits, which will come into force on 1 January 2021, now have a series of options in the MAN Engines range.

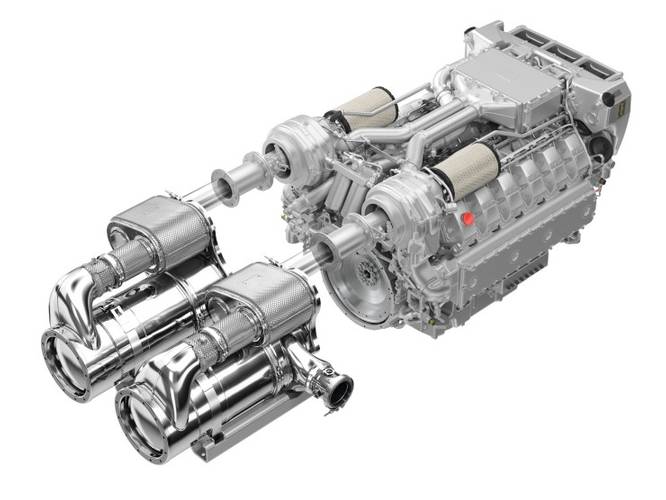

The solution ensuring compliance with the IMO Tier III limits is MAN En-gines’ modular exhaust gas aftertreatment (EAT) system, which was exhib-ited at the SMM trade fair last year. The system sets itself apart with a high level of flexibility and the fact that it is extremely compact, which makes it perfect for meeting the diverse requirements associated with professional shipping. The modular EAT allows for a wide range of installation possibili-ties, as the individual SCR catalytic converter components can be posi-tioned differently, enabling flexible system integration tailored to specific customer needs. However, it is not just flexibility and compactness that this essentially maintenance-free exhaust gas aftertreatment system has to offer – it is extremely lightweight, too.

The key to cost savings and greater system simplicity was the manufactur-er’s decision to avoid a complex exhaust gas recirculation system and heavy, bulky components like diesel particulate filters and oxidation catalyt-ic converters.

MAN Engines’ modular exhaust gas aftertreatment system was showcased at the International Workboat Show in New Orleans, LA, back in late 2017. The IMO Tier III compliance solution is all based on the expertise of MAN Truck & Bus SE. As one of the leading European commercial vehicle manufacturers, the Group has been successfully using SCR systems in the its own trucks in high-volume production since 2006. As well as this, MAN Engines also benefits from the experience in fitting and installation gained from the agricultural and industrial sectors, where the technology has been in serial production since 2015 for in-line and V-engines. The EAT is also showing how practical it can be in field trials for working boats, which are currently running.