OPINION: Regulating Grey Water ... the Time is Now

The IMO’s MARPOL Annex IV is being revised to confirm the lifetime performance of Sewage Treatment Plants (STPs). This may finally bring about grey water regulation – a necessity that is long overdue.Black Water and Grey WaterA ship’s sewage (black water) is collected from toilets, urinals and hospitals. The IMO’s MARPOL Annex IV prohibits its discharge, except when treated by an STP or discharged at > 12nm from the nearest land. A ship’s grey water, collected from showers, wash basins…

ACO Marine Completes Work for Jadrolinija

ACO Marine said it has completed the commissioning of wastewater treatment units aboard the ropax sisters Sveti Krševan, Supertar and Cres operated by Croatian owner Jadrolinija.The three 87.6m vessels were each retrofitted with a Clarimar MF-2 biological-type sewage treatment plant at the Dalmont shipyard in Kraljevica, Croatia, the oldest continuously operating shipyard in the world, with a history dating back to 1729.Italy’s La Fornitrice, ACO Marine’s engineering partner in the region, completed the commissioning of the system aboard Cres, the final ship in the series, in May.

Sydney Ferry Fatality Raises Best Practice Issue

The importance of maintaining chemical toilets onboard ship has been raised following an incident in February onboard a Sydney Harbor-operating passenger ferry in which a high level of toxic gas was detected in a toilet cubicle after a passenger was fatally injured.A 39-year-old passenger was found unconscious in a toilet cubicle aboard the Lady Rose and could not be revived by paramedics. While the reasons behind her death are unconfirmed, during the initial investigation HAZMAT…

ACO Marine Tallies River Cruise Retrofits

ACO Marine has taken a substantial number of orders from European river cruise operators for the supply and retrofit installation of the company’s advanced wastewater treatment systems.The company, the water treatment division of Germany’s ACO Group, will supply wastewater management solutions based around its Maripur NF advanced sewage treatment plant to 10 river cruise vessels scheduled to drydock this winter.In addition to the Maripur NF units, the turnkey package includes grease separation systems…

River Cruisers Get Wastewater Treatment Upgrade

ACO Marine has been awarded contracts to supply its wastewater treatment technology as retrofit solutions to river cruise vessels operating on European waterways. The 232-passenger capacity sisters Ukraina and Moldavia, undergoing refit work at the Ukrainian Danube Shipping Company’s fleet maintenance base in Izmail, Ukraine, will each be retrofitted with a Maripur NF 250 unit. In a separate agreement, a Maripur NF 150 unit will also be supplied to Linz Shipyard for retrofit to the 150-passenger capacity river cruise vessel Carissima. Due to space limitations aboard all these vessels, ACO Marine will use the ships’ existing holding tanks as a bioreactor in the first stage of the treatment process.

ACO Claimers Delivered for Installation on Nibulon Tugs

ACO Marine has delivered three of its smallest Clarimar wastewater treatment units to Ukraine-based Nibulon Shipbuilding and Repair Yard for installation aboard a series of high specification project tugs. Nibulon, Ukraine’s leading exporter of agricultural products, grains and fertilizers with a history dating back to the nineteenth century, entered the shipbuilding and repair sector in 2012, following the acquisition and development of a yard on the Southern Bug River, near the company’s trans-shipment terminal, in Mykolayiv.

Nod for ACO Marine Sewage Treatment Units for use on Great Lakes

ACO Marine has received Transport Canada type-approval for its advanced Maripur NF and Clarimar MF wastewater management systems. “We are delighted to have received approval from Transport Canada. Certification delivers added assurance to Canadian shipowners that our technology is completely compliant with Canada’s stringent sewage discharge requirements for vessels operating in the Great Lakes,” said Mark Beavis, Managing Director, ACO Marine. He added: “Transport Canada certification, issued in December, underpins our strategic decision to grow our Canadian customer base, following the recent appointment of Ontario-based Marine and Offshore (MAO) as our new distributor for the region.

MAO to Support ACO Marine's Projects in Canada

ACO Marine has appointed a new distributor in Canada to help meet increasing demand in the region for wastewater treatment solutions capable of exceeding stringent environmental protection requirements. Ontario-based Marine and Offshore (MAO) Canada will provide sales and technical support across ACO Marine’s range of products, including the MEPC227(64) compliant Clarimar MF and Maripur NF biological sewage treatment plants. Roger McNeill, Managing Director, Marine and Offshore Canada, said: “We are very much looking forward to representing ACO Marine in Canada.

ACO Marine's Clarimar Selected for New Environmentally Sound EcoCoasters

Wastewater streams aboard the two state-of-the-art EcoCoasters Dutch shipyard Royal Bodewes is building for Finland’s VG-Shipping will be managed by a bespoke treatment system designed by ACO Marine. Both 4700dwt EcoCoasters Eeva VG and Mirva VG, due to be delivered this autumn to VG-Shipping, the ship management arm of the Meriaura Group, feature MEPC.227(64)-compliant Clarimar MF-1 treatment plants. Sacha Uittenbogaart, Sales and Marketing Manager with Technisch Bureau Uittenbogaart, ACO Marine’s Netherlands distributor, added: “Both vessels feature systems and technologies designed to reduce substantially the environmental impact of ship operations.

40% Cruise Ships Use Outdated Sewage Treatment Plants

ACO Marine has welcomed the findings reported in the Friends of the Earth 2016 Cruise Ship Report Card, the annual survey of cruise shipping’s impact on the environment, which highlights a growing need for the sector to update its sewage treatment technology. The annual FOE survey, published in June, documented the environmental footprint of 17 cruise lines and 171 cruise ships, finding that a significant proportion of vessels continue to operate out-dated sewage treatment plant. The FOE found that 40% of cruiseships continue to use 35-year-old technology, calling for an urgent upgrade to systems capable of preventing environmental damage from the discharge of poorly treated black, grey and galley waste water streams.

Confusion Surrounds Wastewater Discharge Rules

Confusion surrounding the entry into force date of MEPC 227(64), the amended regulation governing ship wastewater discharge overboard requirements, could see some shipowners falling foul of the new rules. Mark Beavis, the Managing Director of ACO Marine, a supplier of MEPC.227(64) compliant wastewater treatment systems, believes that any further delay from the IMO’s Marine Environment Protection Committee (MEPC) in formally announcing a new date will create further confusion. “A number of shipowners believe the deferred entry into force applies to MEPC.227(64) in its entirety, but this is not our understanding. The International Maritime Organisation, at its MEPC 68 postponed only the entry-into-force date of the ‘Special Area’ sewage discharge requirements.

Treatment Standards Needed for Oily Galley Water

Marine regulators have been urged to introduce performance standards for the separation of fats from galley water before the oily mix enters the onboard treatment process and causes system failure. Currently there are no IMO standards for the separation of fats, oils and grease from galley water, despite the treated water having to comply with the MEPC 227(64) regulation, which does not allow the discharge of any oils. Mark Beavis, the Managing Director of water treatment specialist ACO Marine, said: “Galley water should be free of waste sludge, fats, oils and greases before it enters the treatment process otherwise biological overloading and system blockages can occur, causing system failure and possible pollution.

ACO Marine Unveils New PE Separators

Wastewater management specialist ACO Marine has introduced a new composite grease separator as part of its Lipator and Lipatomat product range. Manufactured from high-density polyethylene (PE) composite, ACO Marine’s new PE-Lipator (manual) and PE-Lipatomat (automatic) separators have been designed to meet market demand for more cost-effective, lighter units capable of delivering the same performance benefits as the stainless steel models, the company said. As with the stainless steel Lipator and Lipatomat units…

First Offshore Reference for ACO's New Clarimar MF

ACO Marine announced it has signed a contract to supply a bespoke version of its new Clarimar MF wastewater treatment plant to the CFT 623 wellhead platform under construction for Dubai’s Dragon Oil. The specially adapted Clarimar MF-2 has capacity to treat 3.5 cubic meters of black and grey wastewater per day and features a sludge tank for liquid discharges from drilling operations. “The offshore oil and gas sector is an important market for ACO Marine,” said ACO Marine’s managing director Mark Beavis.

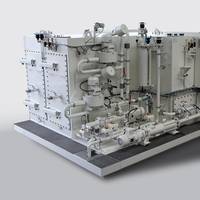

New Water Maker

ACO Marine launched a new water recovery system that is designed to give vessel owners greater capacity to reuse the treated effluent from wastewater treatment plants. The ACO Water Maker WM3 converts treated wastewater into pure distilled technical water for such applications as general surface cleaning, laundry, showering, toilet flushing, engine cooling, etc. According to ACO Marine, the unit has extremely low energy consumption and reduces a ship’s need to take on fresh water in port or to make its own water through reverse osmosis or flash evaporation – both high energy consumers. It is suitable for use onboard all vessel types and can be easily retrofitted to ACO Marine’s Maripur and Clarimar wastewater treatment solutions in addition to third party systems, the manufacturer said.

New Water Maker Launched for Maritime Market

Wastewater treatment systems specialist ACO Marine has launched a new water recovery system that gives vessel owners greater capacity to reuse the treated effluent from wastewater treatment plants. The ACO Water Maker WM3 converts treated wastewater into pure distilled technical water for such applications as general surface cleaning, laundry, showering, toilet flushing, engine cooling, etc. According to ACO Marine, the unit has extremely low energy consumption and reduces a ship’s…

ACO Unveils New Plant for Upcoming Wastewater Rules

ACO Marine, a supplier of advanced wastewater treatment systems, is about to introduce a new version of its established Maripur wastewater treatment range. The next generation ACO Maripur NF sewage treatment system has been specifically developed to ensure operators of specialist tonnage in the passenger and mega-yacht sectors comply with the impending IMO Resolution MEPC 227(64) – including Section 4.2. This requires vessels with 12 or more passengers operating in IMO designated ‘Special Areas’ to effectively treat also Phosphorous and Total Nitrogens.

Breathing New Life into Old Workboats

There is no question that timely repairs and preventative maintenance can extend the life of almost any workboat. It is also true that changing market conditions can lead to renovations to effectively extend the life of many vessels. The one event that triggers many repair projects is the Coast Guard's five-year hull inspection program, often referred to as a "shave and a haircut". Most operators use these occasions to inspect shafts, wheels and do top side repairs as well. With the hull is out of the water, not only can shafts, rudders and wheels be repaired, but also anodes replaced, sea chests inspected and the entire bottom given a coat of anti-fouling paint.

Tanker Trends: ATB Construction Forges Ahead …. Just Not at Torrid 2002 Pace

Construction of Articulated Tug Barge units (ATB) continues to occupy a prominent place in the order books of several shipyards. However the pace of current building and back ordered units is not as high as the 2000-2002 period. "It looks like we are in for a little 'breather' for a while," said Allen Craft, senior vice president of Intercontinental Engineering-Manufacturing Corporation, Kansas City, Mo. The company manufactures Intercon, one of the most popular couplers between the tug and the barge, which makes the ATB concept workable. "Vessel Management Services, a division of Crowley Maritime was a major driving force in this market when they had two different yards each built two ATBs with 9,280 hp tugs and 155,000 barrel barges using our couplers," Craft said.