Towboat M/V Al Sloss Delivered to Canal Barge

C&C Marine and Repair has delivered the M/V Al Sloss to Canal Barge Company, completing the first vessel in a four-boat newbuild series currently under construction for the New Orleans-based operator.The 2,600-horsepower, 87- x 34-ft. towboat was designed by C&C Marine and Repair’s in-house engineering team and constructed on an accelerated schedule, with delivery completed in approximately six months.Delivery of the remaining three vessels in the series is scheduled to follow at two- to three-month intervals.The M/V Al Sloss is powered by two Mitsubishi S12-R main engines…

MDL Invests $9M to Expand Its Flexlay Asset Range

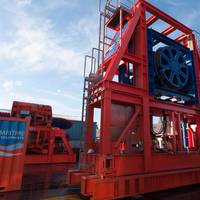

Back-deck engineering specialist Maritime Developments (MDL) has committed $9 million (£7 million) of capital investment to expand its flexlay asset range.The investment covers six new pieces of modular equipment in MDL’s portfolio, including high-capacity tensioners and reel drive systems, as well as the most recent innovation - Wheeled Horizontal Lay System (WHLS).The Wheeled Horizontal Lay System, unveiled by MDL in 202, has already delivered the maiden unit to an offshore…

McAllister Chooses Markey Winches for Newest ASD Tug

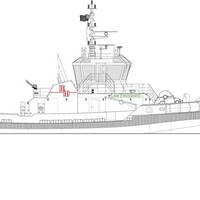

McAllister Towing recently ordered a Markey Machine winch and capstan for the fourth ASD tug of a class-build series being constructed at Washburn & Doughty Associates.Markey is providing a DEPCF-52-75 Class II bow hawser winch, which includes the Markey Render/RecoverⓇ system, a line-display screen and a stainless-steel brake drum. A two-speed CEW-60 electric capstan is also included.“Markey is consistently reliable, a great vendor to work with, and steady. We really wanted electric winches with infinitely-variable speed…

NOV to Supply Cable-lay Equipment for Nexans' New Vessel

NOV reports its Italian group Remacut has secured the cable-lay equipment contract for Nexans' new cable-lay vessel (CLV).Nexans Marine Operations and Norwegian shipbuilder Ulstein Verft entered into a contract in September for the construction of a large DP3 cable-laying vessel, which will be an updated version of the Nexans Aurora vessel, delivered in 2021. The vessel is an ST-297 CLV design by Norway-based Skipsteknisk.Remacut's integrated cable-lay systems feature automated line control equipment capable of performing synchronized bundled-lay operations.

Bay-Houston Towing Orders New Tugs from Sterling Shipyard

Bay-Houston Towing has inked a deal with Port Neches, Texas shipbuilder Sterling Shipyard to build multiple new tugs to serve the Texas Gulf Coast region.The new vessels will be Robert Allan Ltd. designed RAstar 3200-W ASD ship handling and escort tugs for berthing/unberthing large ships and providing escort and emergency response in exposed coastal areas with demanding sea states.“The addition of the RAstar 3200-W further diversifies our fleet and provides an extremely powerful…

David Clark Company: An American Success Story

David Clark Company is best known within the marine market for its wireless and digital headset workboat crew communication systems – the Series 9900 Wireless Marine Headset System and the Series 9100 Digital Marine Headset System. The company has over 20 years of experience designing and manufacturing boat crew communication solutions for a variety of workboats, e.g., patrol boats, fire/rescue craft, and offshore service vessels.But you may not know that David Clark Company started…

Keel Laid for Prysmian's New Cable Layer

Vard's shipyard in Tulcea, Romania, on Wednesday held a keel laying ceremony for the Prysmian Group's newest cable laying vessel.The new 171-meter vessel, an identical sister ship to the state-of-the-art Leonardo da Vinci delivered in 2021, is scheduled to start commercial operation in early 2025.According to the Prysmian Group, both the new ship and the Leonardo da Vinci are the only installation vessels in the world with two rotating platforms of 7,000 and 10,000 tons, bringing the total capacity up to 14,000 tons to ensure the highest carousel capacity in the market.

Otto Candies Orders FibreTrac Offshore Crane from MacGregor for Wyatt Candies Vessel

Cargotec's subsidiary MacGregor has won a contract with the U.S. offshore support vessel owner Otto Candies to deliver an active heave compensated FibreTrac offshore crane.The order was booked in Cargotec’s 2022 first quarter order intake, with delivery expected to be completed by the end of the year. MacGregor told Offshore Engineer that the crane would be installed aboard the Wyatt Candies dive support vessel.The scope of supply includes full delivery of the 150t AHC crane, rated for the client's needs at 100t lifting capacity, together with Lankhorst Lanko®Deep Dyneema DM20 fiber rope for 3400m operational depth."The crane is the first of its type and provides the ability to lift heavy loads at depths that normally require much larger cranes on larger vessels…

Ørsted-Eversource JV Taps Nexans for Revolution Offshore Wind Farm Export Cable

Paris-based offshore cable making and installation company Nexans has won a contract with Ørsted and Eversource to install and protect the export cable link for the Revolution offshore wind farm in the U.S.The project will connect the wind farm to the onshore grid and help Connecticut and Rhode Island states achieve ongoing commitments to develop offshore wind.Located more than 15 miles south of the Rhode Island coast and 32 miles southeast of the Connecticut coast, the 704 MW Revolution Wind Farm will address both states’ energy needs…

KM to Supply Azimuth Thrusters to Sanmar Shipyards

Kongsberg Maritime announced it has signed a contract with Sanmar Shipyards in to deliver US205SFP and US255SFP thrusters for installation on new Azimuth Stern Drive (ASD) tugboats the Turkish shipyard is building for Svitzer.One of the tugs, a 60-ton bollard pull (BP) vessel, is the first of a game-changing, next-generation design by the renowned towage company Svitzer and the internationally recognized naval architects Robert Allan Ltd. The new TRAnsverse 2600 tug can generate higher steering forces than other tugs of a similar size…

Waterjet Propelled Workboat Delivered for work Offshore in the Gulf of Guinea

A 12m workboat built by Strategic Marine has completed sea trials and was delivered to Tullow Ghana Limited.The vessel will be deployed to offshore deepwater projects in the Gulf of Guinea.To this end the vessel has been fitted with an advanced marine propulsion system, with waterjets designed to provide superior manoeuvrability.The workboat is designed to be launched and retrieved from a larger mothership with a single point lifting hook and will primarily perform line handling and crew transfer duties.

'Don't Fear the (Fifie) Reaper': Iconic 118-Year-Old Ship from "the Great Age of Sail" Re-opens

Following a £1million conservation, the Scottish Fisheries Museum in Anstruther, Fife, is set to welcome visitors back onboard the iconic ‘Fifie’ Reaper, the last of the great First Class Scottish Herring Luggers and a rare survivor from the golden age of sail.One of the few vessels in the UK’s National Historic Fleet kept in seagoing condition, the two-masted, 70-ft., 50-tonne Reaper will open to the public on August 4 at her pontoon on Anstruther Harbour, once Scotland’s busiest fishing port.The refurbishmen project…

C&C Delivers New Towboat to Parker Towing

C&C Marine and Repair has delivered the new towboat Olive Parker to Parker Towing Company. The vessel is the first the Belle Chasse, La. shipbuilder has built for the Tuscaloosa, Ala. based company.The 4,400-horsepower towboat measures 147.5’ x 34’ x 10’-9” with the pilot house eyeline measuring at 33’. The Olive Parker was constructed based on a collaborative design by Parker Towing Company and CT Marine, LLC, based in Portland, Maine. The vessel’s design includes two owner furnished CAT 3516B main engines…

TikTok’s Sea Chanteys: How Pandemic Life Has Mirrored Months at Sea

If you’ve perused social media in recent weeks, you may have come across people singing chanteys, which were work songs employed on merchant sailing ships.Historically, chanteys – which are also spelled as “shanties” or “chanties” – began with a sing-out by a crew member recognized as “the chanteyman,” usually someone prized for his voice and ability to extemporize. Fellow sailors would respond with the refrain as they toiled away at their tasks. Now we’re seeing TikTok and Twitter users belting out songs inspired by chanteys to their followers…

Dakota Creek Delivers New US Navy Yard Tug

The U.S. Navy’s first Yard Tug (YT) 808 class tug recently delivered to Naval Base Kitsap, Bremerton Annex. Only 17 days after delivery, YT 808 was in the water assisting USNS Richard Byrd (T-AKE 4) as it moved away from the dock at Naval Magazine Indian Island.“Narrowing the gap between delivery and providing operational support is a priority for our team,” said Mike Kosar, program manager of Support Ships, Boats, and Craft Program Office within Program Executive Office Ships (PEO Ships).

Gallery: Nexans Aurora Fitted With Cable Lay Equipment

Norwegian offshore shipbuilder Ulstein, constructing the Nexans Aurora cable layer for Nexans, has this week said that the installation of Maats cable laying equipment on the vessel has begun.Per Ulstein, Maats’ & Marine Fabricators’ installation team arrived on site on October 14, to begin the installation, which kicked off with the two lay wheels being fitted at the stern. The wheels, in combination with fairings, assist in guiding the cable in a controlled manner as it enters and exits the vessel."Following the lay wheels…

PHOTO: Construction of Nexans Aurora 'Well Underway,' Ulstein Says

Norwegian shipbuilder Ulstein has shared the progress update on the construction of the next-gen cable layer the Nexans Aurora. According to Ulstein, the construction is "well underway.""During a time span of a few days in September 2020, the cable capstan has been installed, the painting process is ongoing and the thrusters are about to be installed," Ulstein said. The hull of the vessel was built in Poland and arrived in Norway in June for final outfitting."The construction of the next-generation cable-laying vessel, the 'Nexans Aurora', is well underway at Ulstein Verft.

Eastern Delivers Tug to Bisso Offshore

Eastern Shipbuilding Group said it has delivered the second of two 80-foot, 5,100-horsepower Z-drive tugs for Bisso Offshore, a division of E.N. Bisso & Son of New Orleans, La.Following delivery on June 11, the newbuild ship-handling tug A. Thomas Higgins completed its bollard pull testing witnessed by the American Bureau of Shipping (ABS) and received its USCG Sub-M Certificate of Inspection (COI). In addition to A. Thomas Higgins, E.N. Bisso has taken delivery of five previous modern Z-drive ship assist tugs from Eastern from 2007, including Josephine Anne, Beverly B, Elizabeth B, Archie T.

Detyens Wins $24 Mln Ship Repair Contract

Charleston, S.C. repair yard Detyens Shipyards has been awarded a $24,235,291 firm-fixed-price contract for a 120-calendar day shipyard availability for the regular overhaul dry-docking of the U.S. Navy oiler USNS Patuxent (T-AO 201). Work is expected to be complete by October 2020.The contract includes options which, if exercised, would bring the total contract value to $27,416,444. The Military Sealift Command is the contracting activity.Work will include main and emergency switchboard cleaning…

US Navy's Newest Yard Tug Launched

The U.S. Navy’s first Yard Tug (YT) 808 class vessel was launched at Dakota Creek Industries' (DCI) shipyard on May 16. The Navy and DCI plan to conduct acceptance trials for the vessel in July, followed by planned delivery in August.The new tug is the first in a series of six being built by the Anacortes, Wash. shipbuilder for scheduled delivery through early 2022. The YT 808 vessels are designed by Robert Allan Ltd. after the Navy’s existing YT 802 Valiant-class tugs to perform towing and ship-handling duties for carriers, surface ships, submarines and barges.

Damen Delivers Workboat to Inverlussa Marine Services

On March 30 in Hardinxveld, the Netherlands, Damen Shipyards Group handed over a Multi Cat 1908 named Patricia Matheson to Inverlussa Marine Services. The company, based on the Isle of Mull, Scotland, will operate the vessel in the aquaculture industry.Inverlussa Marine Service is one of Scotland’s leading workboat companies, supplying vessels to service contracts for amongst others, the offshore wind and fish-farming sectors, throughout the UK and Europe. Patricia Matheson will…

Eastern Launches Tug for Bisso Offshore

Eastern Shipbuilding Group, Inc. has launched the second of two 80’ 5,100 HP Z-Drive tugs for Bisso Offshore, LLC, a division of E.N. Bisso & Son, Inc. The A. Thomas Higgins, currently under construction at Eastern’s Allanton facility, was launched on January 31, 2020.The RAL RApport 2400 Z-Drive ship-handling tug design was provided by Robert Allan Ltd located in Vancouver, Canada. The C.D. White, the first vessel of the series, delivered in January of this year.Long-term customer E.N.

Eastern Delivers Tug to E.N. Bisso

Eastern Shipbuilding Group, Inc. has delivered the first of two 80’ 5,100 HP Z-Drive tugs for Bisso Offshore, LLC, a division of E.N. Bisso & Son, Inc.The M/V C.D. White, handed over on January 8, 2020, is a RAL RApport 2400 Z-drive ship-handling tug design provided by Robert Allan Ltd.The vessel has completed its bollard pull testing witnessed by the American Bureau of Shipping (ABS) and received its USCG Subchapter M Certificate of Inspection (COI).C.D. White and sister vessel M/V A.