AME Renews Partnership with Fluke Reliability, Pruftechnik Group

US-based engineering company Advanced Mechanical Enterprises (AME) has renewed its partnership with Fluke Reliability and Pruftechnik Group and is their official sales representative for Florida, Georgia, North and South Carolina under the leadership of Jorge Garcia.Pruftechnik offers precision alignment and condition monitoring technology, and Fluke, known for its diagnostic tools, aligns with AME’s experience in condition-based maintenance and alignment."We're excited to reignite our partnership with Fluke Reliability and Pruftechnik Group," said Rich Merhige, President of AME.

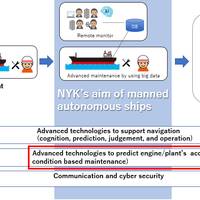

NYK, MTI earn ClassNK Approval for CBM Ship Maintenance Method

NYK and MTI Co., Ltd. received approval from ClassNK for a new condition-based maintenance (CBM) method implemented on NYK-owned coal carrier Noshiro Maru. The certified CBM is a method for monitoring the condition of bearings of large marine diesel engines through temperature data, a method that was adopted in the "CBM Guidelines, Second Edition"4 issued by ClassNK in 2021.In addition, the Diesel Engine Main Bearing Condition Monitoring System, which visualizes bearing temperature data that can be obtained through sensors installed on the main bearings and ship operation data…

World First ‘Exposed’ Fish Farm Features Fiber Optic Structural Stress Monitoring

Ocean Farm 1 operator SalMar and DNV engage Light Structures to deliver precise data for decision support and long-term planningSalmar ASA and Light Structures AS entered an agreement for delivery of a Fiber Bragg Grating technology (FBG)-based structural monitoring system for installation on the Ocean Farm 1 aquaculture facility, located in open water near Frohavet on Norway’s west coast.Making its debut on what is touted as the first ever ‘offshore fish farm’ in 2017, Ocean…

NYK Advances Maritime Autonomy

As the marine industry evolves toward autonomous operations, one of the sticking points traditionally has been centered on maintenance and answering the question: “what happens when machinery needs fixed?”Helping to advance the technologies is the NYK Group, which recently finished a concluded a joint research agreement for developing advanced condition-based maintenance (CBM), a new maintenance and management process for ship machinery which eschews the maritime practice of time-based maintenance (TBM).

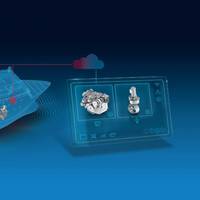

Taking CBM to the ‘Next Level’

As ship owners increasingly use data to schedule ship equipment maintenance, evolving from a calendar-based to a condition-based maintenance (CBM) regimen, Wärtsilä launches its Expert Insight predictive maintenance product, a digital product designed to enable customer support to be delivered proactively by Wärtsilä Expertise Centers to ensure long-term accurate insight for their predictive maintenance strategies. The product is available in combination with a Wärtsilä Lifecycle…

ZF: New CBM Tech for Thruster Systems

At the 15th Maritime Industry Exhibition in early May in Gorinchem, the Netherlands, ZF Marine Krimpen will debut its Condition Monitoring System. ZF's system is designed to help shipyards, shipping companies and fleet operators maintain the safety and efficiency of their ships. It is equipped with various sensors and an intelligent electronic evaluation unit. The system measures vibrations which indicate the condition of the bearings and gears in the thruster's upper and lower gearbox.