AD Ports Expands Shipping Operations in Kazakhstan

AD Ports Group in collaboration with KazMorTransFlot (KMTF), the national shipping company of Kazakhstan, has announced the acquisition and commencement of operations of two tankers designed for the transportation of Kazakhstan's oil across the Caspian Sea.The two oil tankers were named Liwa and Taraz - after ancient cities in the UAE and Kazakhstan, respectively, and have been acquired under AD Ports Group’s joint venture with KMTF - Caspian Integrated Maritime Solutions (CIMS).The two vessels represent a combined investment of USD35 million…

Video: Ship-to-Ship Oil Transfer from FSO Safer Progressing Well

The ship-to-ship transfer of the oil from the FSO Safer to the replacement oil tanker Yemen (formerly known as Nautica) began last week.It was an important milestone in this United Nations-coordinated operation to avert a potential massive environmental and humanitarian disaster off the coast of Yemen.Boskalis reports that the oil transfer is progressing well and will take two to three weeks.Hydraulic pumps have been lowered into each tank of the FSO Safer. During the transfer operation, inert gas is supplied to keep the tank atmosphere at safe levels during the operation.

Survitec Unveils Interactive Safety Monitoring Solution

Survitec has announced a new interactive safety management solution it hopes will substantially improve onboard safety.The Safety Management and Rapid Response Technology Interface (SMARR-TI) uses a graphical monitoring interface to integrate fire detection and fire suppression systems within one system.SMARR-TI, which Survitec developed in cooperation with Turkish shipyard Tersan and Norway’s Havila Voyages, is already in operation on a pair of 15,500gt passenger ships.SMARR-TI…

Mergers & Acquisitions: Alfa Laval Inks Deal to Acquire Scanjet

Alfa Laval signed an agreement to acquire marine tank cleaning equipment supplier Scanjet.Scanjet has expanded from fixed and portable tank cleaning equipment into intelligent tank management, and its solutions and organization will become part of Alfa Laval per an agreement signed on 16 June 2022.“Scanjet is a tank cleaning innovator with exciting developments in the pipeline,” says Alfa Laval’s Peter Nielsen, President of Marine Separation & Heat Transfer, whose business unit will receive the acquisition.

RINA Grants AIP for Hydrogen-powered MR Tanker

Classification society RINA said it has granted approval in principle (AIP) for a hydrogen-powered MR tanker designed by FKAB Marine Design using currently viable technology and fuels that achieves IMO 2050 targets.Conceived by the class society and designed by FKAB, the propulsion is based on combining the ship’s fuel (LNG) with steam to produce hydrogen and CO2. The MR LNG/hydrogen-fuelled vessel is the result of a joint project with ABB and Helbio (a subsidiary of Metacon AB).Antonios Trakakis…

Alfa Laval Sees Growing Orders for FCM LPG Fuel Supply Systems

Alfa Laval reports it is experiencing increased demand for solutions related to liquefied petroleum gas (LPG) as fuel, having seen notable orders for the Alfa Laval FCM LPG in recent months as the marine industry focuses on decarbonization. The low-flashpoint fuel supply system (LFSS) that can work seamlessly with LPG cargo handling systems.Given its lower CO2 footprint compared to traditional marine fuels, LPG is a logical step in decarbonizing the vessels that transport it, Alfa Laval said.

More Than 65% of Ships Contain Asbestos

A significant number of existing and newbuild vessels are operating systems and machinery containing asbestos despite regulations introduced 10 years prohibiting the use of the hazardous substance on board, according to maritime testing facility Maritec.Maritec, which carried out asbestos surveys for IMO compliance between 2011 and 2020, said more than 55% of in-service vessels and 50% of all newbuilds were found to contain asbestos materials.John Rendi, General Manager, Environmental Services…

Wärtsilä, SAACKE Ink Maritime Equipment Deal

Finnish technology group Wärtsilä said it has signed a strategic partnership agreement with SAACKE, the Germany-based supplier of marine firing plants for seagoing vessels, offshore plants and liquefied natural gas (LNG) carriers.A central feature of the agreement is a cooperation regarding safety, in particular with Inert Gas Systems (IGS) and Gas Combustion Units (GCU), Wärtsilä said, adding that the deal will enable both partners to offer larger and more comprehensive scopes of supply…

Centerline Logistics Acquires Saltchuk Marine Services’ California Ship Refueling Ops

Centerline Logistics acquired Saltchuk Marine Services’ California ship refueling business, currently operated by subsidiary Foss Maritime Company. According to a press release from Centerline, this "major acquisition" brings together the combined capabilities of two of the nation’s leaders in petroleum transportation, strengthening Centerline’s position as a provider of around the clock bunkering (ship refueling) services.Through this expansion, Centerline will "substantially…

Ship Power: Inside WinGD's X-DF2.0 Technology

Developments in marine power today are centered on ever tightening legislative mandate which increasingly aim to dramatically reduce and eventually eliminate greenhouse gas emissions to the environment. While the holy grail of being truly ‘emissions free’ is still not feasible, there is much concurrent work in industry and academia to develop and source the fuels, the machinery technology, the logistical infrastructure and the business case for solutions that will meet the 2050 50% emission reduction mandates from the International Maritime Organization (IMO).

Ship Power: WinGD Debuts X-DF2.0 Technology

As shipowners mull ‘the fuel of the future’ and eye ever-stricter emission mandates from the International Maritime Organization, companies throughout the ship design, construction and supply chain continue to innovate to deliver optimum fuel efficiency and emission reduction.Today WinGD unveiled a new technology development to its dual fuel line of engines, a technology designed to significantly cut methane slip, emissions and fuel consumption in its X-DF dual-fuel engines via Intelligent Control by Exhaust Recycling (iCER)…

Tech File: Boiler Tech for LNG Propulsion

With the projected increased adoption of LNG as a fuel in the marine sector, Alfa Laval plays a key role with its tech an knowledge in the area of boilers, which enables ships to deal with boil-off gas (BOG). Specifically, Alfa Laval’s dual-fuel boilers, Gas Combustion Unit (GCU) and services effectively form a portfolio of solutions for BOG safety.To use LNG as fuel, vessels must be able to manage boil-off gas (BOG), the evaporated gas that can increase tank pressure. Alfa Laval has long experience in BOG management on LNG carriers…

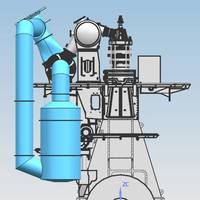

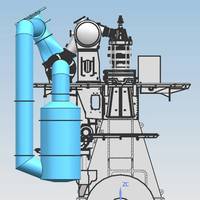

Inert Gas Production for Alfa Laval Training Center

An Alfa Laval Smit Combustion system (FU type) is now installed at the Alfa Laval Test & Training Center in Aalborg, Denmark. The system, which adds inert gas production to the center’s already comprehensive range of full-scale vessel applications, will ensure that Alfa Laval remains at the forefront of developing and optimizing inert gas systems.Inaugurated in 2014, the Alfa Laval Test & Training Center is essentially a full-sized machine room on land, with equipment from all of Alfa Laval’s marine product groups installed in process lines as they would be on a commercial vessel.

Lessons Learned: the Bow Mariner Sinking

The 570-foot Singapore-flagged chemical & oil tanker Bow Mariner sank 15 years ago when the ship caught fire and sustained two explosions, resulting in the deaths of 21 out of 27 crew members, 45-miles off the coast of Virginia, Feb. 28, 2004.The vessel was transporting over three million gallons of ethyl alcohol on a voyage from New York to Texas. It had previously carried methyl tert-butyl ether, MTBE, in its other 22 cargo tanks that were discharged in New York.The cause of…

Alfa Laval's GCU Sales Exceed 100 Units

The Alfa Laval Gas Combustion Unit (GCU) has been chosen for boil-off gas management on more than half of the LNG carriers built during 2018. This brings the total number of GCUs sold to well over 100 units, with new developments promising still greater market potential.Since buying the fledgling technology from Snecma in 2013, Alfa Laval has proven the GCU concept and built up a strong position for the product in the LNG market. This simple and reliable incineration unit for boil-off gas…

Scrubber Manufacturers Slams Singapore Open-Loop Scrubbers Ban

Exhaust Gas Cleaning Systems Association (EGCSA) has attacked Singapore's restrictions on open-loop versions of the systems as "disappointing" and "politically motivated."The scrubber manufacturing industry body said in a press release: "The recent announcement by the outgoing CEO of the Maritime and Port Authority of Singapore (MPA) banning the discharge of process water from open loop scrubbers for vessels visiting Singapore came without prior notice or discussion with the IMO despite the fact that the Singapore MPA is a signatory to MARPOL Annex VI."The MPA provided neither scientific evidence for its decision nor was the industry invited to consultationit said.

Gothia Tanker Alliance Delivers Fure Valö

Europe's leading network for smaller and intermediate size tankers Gothia Tanker Alliance announced the delivery of the fourth vessel LNG-fueled vessel Fure Valö.The vessel was named on the 17th of November and delivered to owners Furetank on November 27, the company tweeted. Fure Valö has been delivered at the Chinese Avic Dingheng shipyard.Fure Valö is vessel number four in a the serie of six climate smart, high quality new buildings that will join the Gothia Tanker Alliance.It is a part of the six-vessel series ordered by the Gothia Tanker Alliance members Furetank, Älvtank and Erik Thun, Gothia Tanker Alliance said.Furetank Rederi AB, Rederi AB Älvtank and Thun Tankers BV are building six intermediate size tankers at Avic Dingheng Shipbuilding Ltd.

Learn to Weld with a Virtual Personal Trainer

The Fohnsdorf Training Center is located in Styria, Austria. To train welders, it uses a virtual welding system – the Virtual Welding simulator from Fronius, the Austrian technology leader. The simulator employs a virtual trainer to provide 1:1 training for the center’s students, an approach that has a positive impact on training quality.A young student carefully guides the welding torch. The weaving motions she makes as she welds the single-V butt weld in front of her appear very composed, an impression that is confirmed by the consistently positive feedback from her trainer.

Coldharbour Targets Greek Market

“Posidonia could not have come at a better time for us,” said Andrew Marshall, Coldharbour Marine Chief Executive, a few days before Posidonia opened its doors to the global shipping community in Athens. “We are in the final stages of a successful ballast water treatment installation for one of our key Greek clients, and we are in negotiations with several other potential customers in this important market. The ballast water treatment sector is picking up at last.”“Greek shipowners are important to us…

New BWTS for Big Bulk Carriers

U.K.-based ballast water treatment systems (BWTS) manufacturer Coldharbour Marine has launched a new treatment process designed specifically for large dry bulk vessels and ore carriers. The system uses the company’s existing inert gas based GLDTM treatment plant to meet the needs of large bulk carriers, which often ship large volumes of ballast water in upper wing tanks and discharge it directly into the sea. The IMO International Convention for the Control and Management of Ships'…

FPSOs: New Storage Tank Explosion Frequencies

The fatal explosion in the pump room on the Brazilian FPSO Cidade de São Mateus in February 2015, demonstrated the potential for major accidents on this type of unit. Although there has never been an explosion in the oil storage tanks of an FPSO, there is a potential for such an event and offshore operators should assess the risks of such events to design against them. It is therefore imperative that risk assessments of FPSOs address this type of event. For this, they need to estimate its annual likelihood of occurring.

Shuttle Tankers - Safe, Flexible, Efficient

Shuttle tankers are an alternative to subsea pipelines. Typically for large water depths. For harsh weather operation the use of shuttle tankers is a necessity. DNV GL has incorporated the latest findings related to their design, operation and safety in an updated shuttle tanker paper. Shuttle tankers transport crude oil from offshore oil fields to terminals where use of subsea pipelines are not feasible. Major deployment areas include the North Sea and the Brazilian offshore fields. The global fleet has been growing steadily for decades, comprising 88 ships by the end of 2016. Two owners, Teekay Corporation and Knutsen NYK, account for 62 per cent of the fleet, and 64 per cent of all shuttle tankers are DNV GL-classed.

New Shuttle Tanker Design for Teekay

A new shuttle tanker concept developed by the world’s largest shuttle tanker services provider, Teekay, will offer a new level of innovation, says Wärtsilä, whose smart technology solutions will be featured on the new vessels. To date, Teekay has ordered four of these ‘next generation’ ships, each to be built at the Samsung Heavy Industries (SHI) yard in South Korea. According to Wärtsilä, the newbuilds will feature a broad assortment of its latest technology innovations, all of which are central to the concept’s overall performance gains.