"You're gonna need a bigger crane..."

Offshore wind turbines are reaching new heights both literally (meters), and figuratively (megawatts). As the demand for larger turbines surges, so do the challenges faced by offshore installation contractors, which need to come up with bigger vessels, and, consequentially, bigger cranes for those vessels.When I took on the assignment to produce a piece focusing on heavy-lifting cranes and deck machinery for OE, I immediately thought of Huisman as a company best suited for coverage in this space…

A New Generation of WTIVs

WTIVs have always been fuel-hungry. Now they are being tasked with installations that are further, deeper and heavier.Offshore wind farms continue their march into deeper water, further from shore, with turbines that can now reach more than 270 meters high with blades 120 meters long. Designers and OEMs are pushing efficiency to new levels to contain OPEX on the new-generation jack-up WTIVs taking them up there.Danish ship design firm Knud E. Hansen has chosen specialization for its Atlas A-class WTIV, a smaller derivation of its massive C-class design.

Sembcorp Marine Orders NOV Equipment for Maersk's Wind Turbine Installation Vessel

Singapore-based Sembcorp Marine has awarded NOV contracts to supply equipment for the wind turbine installation vessel (WTIV) it is building for Maersk Supply Service. This will be the first WTIV for both Semcorp Marine and Maersk Supply Service. The vessel, ordered by Maersk from Sembcorp Marine in March, will be chartered by Empire Offshore Wind, a joint venture between Equinor and BP, and will be used for the installation of 15MW Vestas wind turbines at the Empire Wind offshore wind project in the U.S.Announcing the equipment order…

NOV to Design and Equip Cadeler's New WTIVs

NOV announced it has signed a contract to design and equip two wind turbine installation vessel (WTIV) newbuilds for Denmark-based Cadeler. The new vessels will have the largest jacking capacity in the industry and will be able to transport and install seven complete 15 MW turbine sets or five sets of 20-plus MW turbines, NOV said.Under its deal with COSCO SHIPPING Heavy Industry and Cadeler, NOV will supply the overall design for the GustoMSC NG-20000X self-propelled jack-up…

KNUD E. HANSEN Unveils WTIV Design

Naval architecture firm KNUD E. HANSEN has unveiled a new wind turbine installation vessel (WTIV) design engineered to carry and install up to four new-generation 14 megawatt wind turbines.The Atlas A-class vessel is specifically dimensioned for transporting and assembling wind turbines on top of pre-installed foundations, the designer said. The foundations, which are heavy but do not require jacking, can be efficiently installed from a heavy-lift vessel. As a result, the Atlas A-class can be entirely optimized for the jacking operation…

Saudi IMI Signs Jack-up Deal with GustoMSC

Saudi-based International Maritime Industries (IMI) has announced that it had signed a licence agreement with GustoMSC, a subsidiary of Houston rig and equipment builder National Oilwell Varco (NOV).The agreement entails a new GustoMSC drilling jack-up design which will utilize the modern manufacturing capabilities currently planned for at IMI, said a press note.As a result of the agreement IMI will be fully prepared for its first production operations anticipated in 2021.Fathi K Al Saleem, CEO of IMI, said: "This is a major step for IMI in securing the required knowledge and getting the best rig design which will be tailored to our state of the art construction capabilities…

ABS, Industry Experts Tackle MODU Safety Issues

ABS, the leading provider of classification and technical services to the offshore industry, collaborated with industry experts during its annual Special Committee Meeting held recently to discuss the ABS Rules for Building and Classing Mobile Offshore Drilling Units (MODUs), with the goal of assuring that Rule requirements align with industry needs. “Our leadership position in the offshore sector is based on the ability to provide exceptional guidance and services,” says ABS Executive Vice President of Global Offshore Ken Richardson. More than 50 participants, including delegates from major owners, designers, shipyards and technical representatives from ABS, provided input at the Special Committee Meeting that will be used to refine ABS Rules.

Ulstein, SeaOwls Partner for Heavy-lift Jack-Up Design

Ulstein Design & Solutions B.V. (part of Ulstein Group) and SeaOwls B.V. are partnering to combine the former’s track record in heavy lift vessel design with the latter’s experience in jack-up technology and engineering to jointly develop the next generation self-propelled heavy lift jack-up vessel. The new design aims to serve the needs of offshore wind industry, but will also be suitable for operations in the offshore oil and gas market. Rather than developing a scaled-up version of a conventional heavy lift jack-up vessel, a complete new design is being developed by the two companies.

Liftboat SUDA 300-L4T Delivered

A. K. Suda (SUDA) has successfully completed the design of a 300 ft. (91.5m) truss-legged liftboat. This vessel is being delivered to its owners in 1st Quarter 2016. This vessel follows on the heels of the world’s largest pipelegged liftboat, the SUDA 335-L3, delivered last year. This state-of-the-art vessel is a 4-legged, selfpropelled, self-elevating, general service liftboat, known as the SUDA 300-L4T. It is ABS classed with Unrestricted Service, A-1, AMS. The hull dimensions are 164 ft. x 98 ft., 5 in x 14 ft., 9 in, (50m x 30m x 4.5m). It has one leg encircling crane of 200T, and a 70T pedestal crane. The quarters arrangement can accommodate 85 persons including crew. It has a cargo deck area of 740 m2 of which 450 m2 is rated for 10 t/m2 and the balance for 5 t/m2.

Keppel Secures $85 mln Liftboat Order

Keppel FELS Limited (Keppel FELS), a wholly owned subsidiary of Keppel Offshore & Marine Ltd (Keppel O&M), has secured a contract from Crystal Heights Holdings Limited, a company specializing in the offshore oil and gas market, to build a high specification liftboat worth $85 million. The liftboat is designed by Keppel O&M's liftboat design specialist, Bennett Offshore in collaboration with Keppel FELS. Scheduled for delivery in 4Q 2017, the liftboat will have provisions enabling it to operate in China, the Middle East and the Gulf of Mexico. Liftboats are dedicated vessels used to support offshore platforms in construction, accommodation and well intervention as well as maintenance and installation.

ABS to Class Newbuild Semisubmersible, Liftboat

Baoham Offshore (HK) Ltd. has selected ABS to provide classification services for newbuilds in China. ABS, a provider of marine and offshore classification services, has been selected by Baoham Offshore (HK) Ltd. to class a drilling semisubmersible and a liftboat. "This award is a reflection of the solid reputation ABS has built as a classification society over more than 30 years in China," said ABS Executive Vice President of Energy Project Development Ken Richardson. According to Baoham Offshore General Manager Xu Jun, the company's goal is to be a first mover in China.

OTC 2015: ABS Addresses Improved Jackup Safety

Multi-pronged program promotes safe jackup operations. ABS, a leading provider of maritime and offshore classification services, is investing in research and development (R&D) that will provide industry-critical data to promote jackup safety. "The research work ABS is carrying out will be valuable to drilling contractors that are looking for guidance on improving the safety of their jackup fleets," says ABS Chairman, President and CEO Christopher J. Wiernicki. Jackup issues constitute…

New Recommendations to Avoid Jacking System Failure

A joint industry project on jacking system maintenance and inspection has resulted in a new DNV GL Recommended Practice. This provides guidance to ensure the correct and safe functioning of rack and pinion style jacking systems. The objective is to reduce the risk of gear failure, resulting in lower costs and higher availability throughout the asset’s life time. The consequences of jacking gear failure can be severe and, while the problem is acknowledged by the industry, the correct maintenance and inspection of the jacking systems have proven to be challenging due to the high turnover of people with specific knowledge on board, the evolving nature of the systems and the intermittent use of the systems.

Chinese Shipyard Notified to Halt on Rig Jack-up System

Dalian Shipbuilding Industry Offshore has been notified by Friede & Goldman Marketing BV (F&G) to temporarily suspend construction of its rig jacking systems. Arising from the recent accident during the construction of a similar rig at the Jurong Shipyard in Singapore, Prospector Offshore Drilling S.A. which has four jack-up rigs under construction in Dalian Shipbuilding Industry Offshore Co. Ltd. (DSIC-Offshore), has been informed that DSIC-Offshore has been notified by Friede & Goldman Marketing BV (F&G) to temporarily suspend work on the rigs’ jacking systems, pending testing. F&G is the engineering firm that has designed the jack-up and which has supplied the entire jacking system through their own sub-suppliers.

DNV’s new Jack-up Rule Book Hits the Street

A new dedicated rule book for self-elevating units will guide designers and yards to class their designs and newbuilding projects. The rule book clearly explains the DNV and international regulations and standards. Adaptations from the traditional Offshore Standards include additional class notations and alignment of material and jacking systems requirements based on feedback from industry experts and adapted survey procedures. This dedicated rule book for self-elevating units…

DNV Launches new Jack-up Rule Book

The new rule book clearly explains the DNV and international regulations and standards. Adaptations from the traditional Offshore Standards include additional class notations and alignment of material and jacking systems requirements based on feedback from industry experts and adapted survey procedures. This dedicated rule book for self-elevating units clearly provides the specific considerations required for Jack-Ups to prevent interpretations that may lead to imposing additional requirements without any safety benefits. These considerations are especially relevant for Jack-ups, taking into account their dual fixed/ floating nature. DNV’s Offshore Class Product Manager, Michiel van der Geest, explains that “We have focused on making a user friendly rule book with clear guidance.

FG International’s First Single Pole Lifter Installation

FG International Holland BV, the Dutch Special Lifting company, has recently applied a brand new construction called FG Single Pole Lifter. Willtéco was awarded the high profile job to construct and exchange gearboxes on a jack-up platform in IJmuiden, The Netherlands. While the jack-up does have two sizeable deck cranes, both cranes cannot fully reach the enclosed area where the gearboxes are located. As an alternative to putting a huge land based crane on the quayside, FG built…

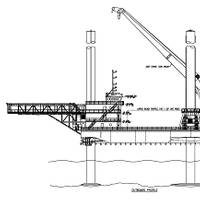

Drydocks World to Build Self Elevating Platform

Drydocks World, the well established ship repair, conversion and new building Group announced today that it has signed a contract with Mumbai-India based construction group, Afcons Infrastructure to provide detail engineering, procurement, construction and delivery of a Self Elevating Platform AF SEP Samrat. The 45metre long flat bottom pontoon barge, which will be built at the Dubai facility, can be jacked up with four spuds and a jacking system with an elevated weight of 2928 tonnes approximately.

Liftboats: Unique Above the Sea

\While most boats have to find shelter or tough it out in heavy weather, the lift boat simply jacks up her hull and avoids the waves. Conventional vessels are often defined by their hull length, but it is the length of the jacking legs that is the significant number for lift boats. Having recently delivered a lift boat with massive 320-foot legs, naval architect A. K. Suda, Ltd. are currently overseeing the construction of two of their latest designs. The larger of the two has 300-foot lift legs.

Keppel FELS clinches $110M rig order

Keppel FELS Limited (KFELS), the offshore arm of Keppel FELS Energy & Infrastructure Ltd. (Keppel FELS), has signed a contract with Chiles Offshore LLC (Chiles) to build a $110 million jack-up rig of KFELS MOD V "B" design, cantilevered jack-up rig. Work is expected to start immediately, with delivery scheduled for around the second quarter of 2002. This rig is one of KFELS' ultra-premium proprietary jack-up designs which has been modified in this case for non-harsh environment usage. It is designed to be able to exceed the operating capabilities of conventional non-harsh environment jack-up rigs and will be built to a leg length of 475 ft., with an option to extend this to 545 ft. "Our goal is to augment our position in the ultra-premium, deep-water jack-up market niche.

New Orders for SBM Offshore

A Letter of Intent was signed on April 26, 2006 by Chevron Frade LLC, a subsidiary of Chevron, and Single Buoy Moorings Inc under which the parties undertake to execute a lump sum Engineering, Procurement, Construction and Installation (EPCI) contract covering the provision of an FPSO based on the conversion of the VLCC 'Lu San' from SBM inventory. In addition to the EPCI contract the parties intend to enter into an Operations Contract for a minimum period of three years. The FPSO, moored by an internal turret accommodating 33 risers, will be fitted with topsides for the production of 100,000 barrels of oil, treatment and compression of 106 million standard cubic feet of gas and treatment and injection of 150,000 barrels of water per day.