Dredge Construction Booming in Competitive US Market

A dredge building boom that has been underway in the United States for several years is still going strong as the market remains highly completive for solid project workloads in both the public and private sectors.According The Mike Hooks Report, an analysis of the FY22 U.S. federal dredging market compiled in September 2023 by Michael Gerhardt, senior director of government affairs at Mike Hooks, LLC, 52 Jones Act dredging companies were awarded federal dredging contracts in FY2022.

USACE Awarded a Slew of Dredging Work in the First Half of 2023

The U.S. Army Corps of Engineers (USACE) is snapping back from the doldrums of COVID-19, wrapping up a strong first half of 2023 with a slew of awarded dredging work.“The federal government is no different from state and local governments, nor the private sector when it comes to COVID-19 work related recovery and USACE is not an exception,” said William P. Doyle, CEO of the Dredging Contractors of America. “The Army Corps has been steadily issuing contract awards since February, and that’s on the award side.

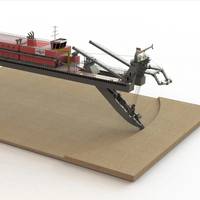

Mike Hooks Christens New Dredge

A new cutter suction dredge (CSD) has been christened for Westlake, La. based dredging contractor Mike Hooks.The 27-inch CSD Lorraine Hooks was built at Southwest Shipyard in Galveston, Texas and delivered to its owner earlier this year 2023. The newbuild is named after the wife of the company's founder.C-Job Naval Architects, based in the Netherlands, served as systems integrator and was responsible for the full design scope including the majority of the dredge equipment for the dredge on behalf of Mobile, Ala.

Pascagoula River Dredging Underway

Dredging operations are underway on the Pascagoula River in Pascagoula, Miss., and the U.S. Coast Guard is urging mariners in the area to exercise caution.The Mike Hooks cutter suction dredge E. Stroud is currently conducting dredging operations for the U.S. Army Corps of Engineers just north of the U.S. Highway 90 Bridge on the Pascagoula River. Operations are expected to take approximately two weeks.The dredging pipe is marked and illuminated at night, and mariners are advised to stay within the marked channel while transiting the area, the Coast Guard said.The dredge can be contacted via VHF radio on channels 13 and 16, and it is displaying lights and day shapes indicating the safe side for passage in accordance with Inland Navigation Rule 27.

Southwest Shipyard Launches Mike Hooks' New Dredge

A new new 27-inch cutter suction dredge for Mike Hooks, LLC has been launched at Southwest Shipyard in Galveston, Texas.The Lorraine Hooks, named after the wife of the company's founder Mike Hooks, will now get a ladder gantry and anchor boom stops, a fresh coat of paint in Houston, and then return to Galveston for equipment install.Once outfitted and complete, the 300- by 50-foot Lorraine Hooks, with a dredging depth of 75 feet, will be deployed on both coastal restoration and…

2022 US Shipbuilding Report

It’s a common story in the U.S. shipbuilding industry today. A piece of equipment that used to be available for delivery on short notice—maybe in one or two weeks—now must be ordered months or more in advance, and it costs double. Add to this rising steel prices and the labor issues that have pervaded nearly all industrial sectors since the early days of the pandemic, and it’s clear that business is far from usual for American shipyards.Bollinger Shipyards president and CEO, Ben Bordelon…

Army Corps and Dredging Industry Sign MOU to Improve Safety Culture

The U.S. Army Corps of Engineers (USACE) is working with industry partners to create and sustain an injury-free workplace and safety-first culture for the men and women who work in dredging and marine construction.On June 3 in Washington, D.C., the USACE inked a strengthened partnership agreement with the national safety voice for the dredging and marine construction industry, the Council for Dredging and Marine Construction Safety (CDMCS), and the groups discussed ways to meet shared safety goals.

Bigger, Stronger: The U.S. Dredging Fleet is Growing

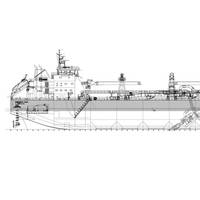

The U.S. dredging fleet is growing. Presently on order and under construction is a raft of in-demand equipment that will help to keep America’s ports and waterways open, safeguard coastal communities and maintain the vital flow of maritime commerce to, from and through the U.S.In August, Eastern Shipbuilding Group cut first steel for a new trailing suction hopper dredge (TSHD) it is building for Weeks Marine, and the keel was laid the following month at the builder’s Allanton Shipyard in Panama City, Fla. The new 6,540 cubic meter capacity dredge R.B.

Eastern Lays Keel for Weeks Marine's New Hopper Dredge

Eastern Shipbuilding Group conducted the keel laying for the new trailing suction hopper dredge (TSHD) it is building for Weeks Marine.This new U.S. flag dredge R.B. Weeks, ordered by Weeks Marine in April, is be constructed at Eastern’s Allanton Shipyard in Panama City, Fla., for scheduled delivery in early 2023. Steel cutting commenced on August 19.R.B. Weeks is the second TSHD Eastern is building for the Cranford, N.J.-based marine construction and dredging contractor, following the Magdalen delivered in December of 2017.The R.B. Weeks is named in honor of Richard B.

Manson Orders US' Largest Hopper Dredge

Manson Construction Co. signed a contract with Keppel AmFELS to build a new hopper dredge at the shipbuilder's facility in Brownsville, Texas, the Seattle-based marine contractor announced Monday. The new dredge is scheduled to be fully operational by spring 2023 and continues a dredge building boom currently underway in the U.S.The self-propelled trailing suction hopper dredger (TSHD) Frederick Paup will be the largest in the United States, representing Manson’s single biggest investment in its 115 year history, the company said.

Mike Hooks Orders New Dredge at MPW

Mike Hooks, LLC has signed a deal with Mobile, Ala. fabricator Mobile Pulley Works (MPW) to design and build a new 27-inch cutter suction dredge (CSD).The new CSD Lorraine Hooks is being designed to the latest industry standards to maximize safety, comfort, and efficiency. The dredge will house on-board crew accommodations to provide comfort and convenience for personnel while they are onboard. The new accommodations and lever control room will be constructed on vibration mounts to reduce fatigue caused by harmonic vibrations and noise levels.

USACE Participation Soars, Membership Expands at CDMCS

The Council for Dredging and Marine Construction Safety (CDMCS) convened this week in Washington, DC on the heels of its Pipeline Task Force Meeting to discuss OSHA regulatory updates, best practices for employee training documentation, opioid identification and prevention, and incident/injury trends in the industry.Representatives from The Dutra Group, Inland Dredging, Great Lakes Dredge & Dock, JT Cleary, Manson Construction Co., Mike Hooks, Norfolk Dredging, and Weeks Marine attended, as well as the Associated General Contractors of America (AGC), the American Waterways Operators (AWO), Coastal and Marine Operators Pipeline Industry Initiative (CAMO), and a record number of U.S.

American Pride: Working Hard in the US Dredging Industry

We have had a great first couple of months at the Dredging Contractors of America. As the new CEO and Executive Director, I have begun to visit the companies, their facilities and associated dredging projects. So far, I have surveyed the beach re-nourishment project in Ocean City, Md. undertaken by Great Lakes Dredge and Dock. I’ve canvassed Weeks Marine’s repair and yard facility in Jersey City, N.J. In the last week of February, I visited Mike Hooks Inc.’s corporate headquarters and boatbuilding and repair yard in West Lake, La.

William P. Doyle Appointed as DCA Executive Director & CEO

The Dredging Contactors of America’s (DCA) has selected the Honorable William P. Doyle, Sr. as its new Executive Director and Chief Executive Officer (CEO). William Doyle currently serves as a Commissioner with the U.S. Federal Maritime Commission having been unanimously confirmed twice by the U.S. Senate as a Presidential Appointee, and remained onboard with the Administration of President Donald J. Trump. Mr. Doyle served over a decade as an officer in the U.S. Merchant Marine as an engineer aboard numerous classes of vessels. He is a licensed attorney and marine engineer. Combined, he has over 25 years of experience in transportation and maritime policy serving in senior level executive roles including Presidential appointee and previously chief-of-staff…

Capsized Boats Leave Mile-long Sheen in Mobile

Vessels were being urged to travel carefully through the Mobile shipping channel on Tuesday after two boats containing 2,000 gallons of oil capsized the previous night, leaving a mile-long sheen, the U.S. Coast Guard Mobile Sector said. Five crew members were rescued from the 52-foot (15-metre) Delta Amber tugboat and the 26-foot (8-metre) Nicholas as the two ships sank around 10:45 p.m. The cause of the capsizing of the two boats, which were both employed in a dredging operation in the bay by Mike Hooks Inc, is under investigation by the Coast Guard. A boom was placed around the sunken boats to prevent the fuel and lubricating oil inside them from disseminating into the bay. A salvage operation is being led by Oil Recovery Corp.

Bean Dredging Awarded Contract

awarded a dredging contract at Pascagoula, Mississippi to Bean Dredging L.L.C. Orleans. The award serves as a sharp rebuttal to Mike Hooks, Inc., a competing dredger, which had previously filed a protest challenging the award prematurely and without any substantial factual basis. The Hooks protest, which was filed on October 21, 2003, essentially challenged the US Coast Guard’s determination that the dredge MERIDIAN, which Bean Dredging proposed to use on the Pascagoula project, qualifies for a coastwise endorsement based on the citizenship of its owners. The award represents a rejection of this frivolous challenge that has already caused a six week delay in the execution of the project. Bean Dredging L.L.C.

Lake Charles Dredger Wins Contract

The New Orleans District, USACE, awarded a $1.43 million contract to Mike Hooks Inc., of Lake Charles, La., to build an underwater sill in the Mississippi River to check saltwater intrusion. Mike Hooks Inc., the low bidder, will use cutterhead Dredge 32 to build the sill from river-bottom sediment to protect fresh water for New Orleans. The same company and same dredge complete the job successfully in 1988. The 20-ft. high sill will be constructed at mile 63.7 above Head of Passes, where the river is 80 ft. deep. Location is at the upstream end of the BP Amoco oil refinery, where the 1988 sill was built, 12 miles downstream from the Belle Chasse water intake.