Venezuela to Cut Oil Output

Venezuela's state-run oil company PDVSA has begun cutting crude production because it is running out of storage capacity due to an ongoing U.S. oil blockade that has reduced exports to zero, piling more pressure on an interim government trying to hang onto power in the face of U.S. threats of more military action.Caracas is in political crisis under an interim government after President Nicolas Maduro and his wife were captured by U.S. forces on Saturday. The OPEC country's oil exports, its main source of revenue, are now at a standstill following a U.S.

Offshore Wind: Building the UK’s First Nearshore Artificial Nesting Structures

As offshore wind rises to meet ambitious climate goals, balancing the need for infrastructure with maintaining biodiversity has become a pressing challenge. One innovative, recent example is the installation of the UK’s first nearshore artificial nesting structures, designed to safeguard seabirds while enabling the development of the world’s single largest offshore wind farm.Hornsea 3, developed by Ørsted, plays a critical role in the UK’s clean energy transition. Yet the project faced a significant environmental challenge by needing to protect the black-legged kittiwake…

LNG: Greenwashing or Realism

The October delay at IMO of its Net Zero Framework continues to spark debate, and enthusiasm, about net zero fuel choices, including what LNG’s role should be.Debate is expected to continue too, as shipowners face a more complicated regulatory landscape now. Despite the uncertainty created by the delay, regulations continue to force emissions reductions, including existing IMO regulations such as CII and regional regulation such as FuelEU.With the number of dual-fuel LNG ships being ordered higher than methanol or ammonia alternatives…

Denso Unveils Anti-Corrosion System for Marine Structures

Denso, a corrosion prevention and sealing technologies specialist, has introduced the SeaShield Series 2000HD, a corrosion protection system designed for piles and pipes in coastal and offshore environments.The system combines petrolatum tape with a high-density polyethylene (HDPE) outer jacket and is intended for use on dock piles, riser pipes and exposed piping in splash and intertidal zones.It accommodates cylindrical, square, hexagonal and H-pile shapes, along with bracing…

RWE Drops Bubble Curtain to Silence Construction Noise at Sofia Offshore Wind Farm

RWE has deployed a bubble curtain technology in the U.K. for the first time to protect marine life from the construction noise at its Sofia offshore wind farm.RWE has been working with Hydrotechnik Offshore to introduce an innovative underwater noise-abatement technology, known as a bubble curtain, for offshore wind farm construction in the U.K.The deployment at the Sofia offshore wind farm, located 195km off the coast of England, represents a significant step in protecting marine life from underwater noise generated during piling activities.The bubble curtain…

GBM Works' New Tech Challenges Noise Pollution in Wind Turbine Installation

GBM Works has made progress with the development of its Vibrojet technology, designed to address noise pollution affecting marine life during the installation of foundation piles by using vibrations and water jetting, instead of traditional piling methods.In collaboration with MSA-Service and their data acquisition platform, multiped, the first large-scale tests of the technology are currently underway. The core of this technology, as GBM explains, lies in the application of water and vibrations. "Instead of forcefully hammering a pile into the seabed, we use water and vibrations.

US Plans to Halt Vessels as it Aims to Disrupt Iran's Oil

President Donald Trump's administration is considering a plan to stop and inspect Iranian oil tankers at sea under an international accord aimed at countering the spread of weapons of mass destruction, sources familiar with the matter told Reuters.Trump has vowed to restore a "maximum pressure" campaign to isolate Iran from the global economy and drive its oil exports to zero, in order to stop the country from obtaining a nuclear weapon.Trump hit Iran with two waves of fresh sanctions in the first weeks of his second-term…

Marine Masters Secures Wellhead Platforms Installation Job Off India

Dutch offshore contractor Marine Masters has secured work on an offshore installation project for the greenfield Bhasker A & B platforms, designed and constructed by Indian energy company SunPetro.The project, managed by main installation contractor ACE Pipeline and directly overseen by Consolidated Support Services PTE LTD (CSS), involves the development of two wellhead platforms featuring jackets with integrated boat landings and topsides.The Marine Masters work encompasses detailed preparation for lifting and mooring activities…

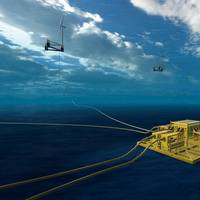

Floating Wind and the Taming of Subsea Spaghetti

Preparing for industrialization, the floating offshore wind industry is tackling its unique mooring and cabling challenges.The idea of keeping floating offshore wind platforms in place using dynamic positioning has been considered. The trouble is: it could take up to 80% of the electricity generated by the turbine to do it.So, as Maersk Supply Service said a few years back: In a field of 100 turbines with 4-5 mooring lines each, there is going to be a lot of subsea “spaghetti.” It’s not a problem unique to the industry…

AYK Energy to Supply Batteries for Mureloil's New Diesel Electric Tanker

Marine battery manufacturer AYK Energy reports it has secured a contract to build a new 4,200 KWh battery for Spanish ship owner Mureloil. The agreement will see AYK’s Aries + battery supplied on a new 7999 DWT diesel-electric product tanker being built for Mureloil at Astilleros Murueta shipyard near Bilbao.AYK founder Chris Kruger said the vessel will be able to operate on zero emission battery power while entering and exiting port immediately improving air quality and cutting emissions in built up port areas.

Red Sea Diversions, Tariff Risks Send Ocean Shipping Soaring

Spiking ocean shipping rates, vessel backups at seaports and empty container shortages - issues that wreaked havoc on global trade during the COVID pandemic supply-chain crisis - are back as the industry enters its busy season."There is a cocktail of uncertainty and disruption across global ocean freight supply chains," said Peter Sand, chief analyst at pricing platform Xeneta."It is the speed and magnitude of this recent (rate) spike that has taken the market by surprise," he said.On Friday…

USACE to Continue Duluth Pier Repairs

The U.S. Army Corps of Engineers will continue repairing its Duluth southern Vessel Yard Pier with Phase 2 beginning in July.Repairs this year are estimated to end around November and resume Spring 2025 with completion in the Spring of 2026.Michels Construction Inc. of Brownsville, Wisconsin was awarded the contract for encasing the existing south pier and slip headwall structures with steel sheeting and piling, site lighting, storm drainage, shore power improvements, replacement of bollards with helical pile foundations and concrete paving.

Acteon’s LDD Getsy Busy at Scottish Port's Infrastructure Upgrade

LDD, an Acteon company, has been awarded a contract by George Leslie to perform piling works on the Kennacraig Port's ferry terminal in Scotland.LDD, a marine foundations brand within Acteon, is supplying reverse circulation drilling (RCD) services to George Leslie to construct a new sheet pile quay wall at Kennacraig Port.The project is being undertaken in challenging ground conditions with hardness ranging from 90 to 150 MPa.Kennacraig is an existing operational ferry terminal, and the piling works will upgrade the port infrastructure to facilitate the use of new vessels.

Somali Pirates' Return Adds to Crisis for Global Shipping Companies

As a speed boat carrying more than a dozen Somali pirates bore down on their position in the western Indian Ocean, the crew of a Bangladeshi-owned bulk carrier sent out a distress signal and called an emergency hotline.No one reached them in time. The pirates clambered aboard the Abdullah, firing warning shots and taking the captain and second officer hostage, Chief Officer Atiq Ullah Khan said in an audio message to the ship's owners."By the grace of Allah no one has been harmed so far," Khan said in the message, recorded before the pirates took the crew's phones.

The Headwinds of US Offshore Wind Development

On March 29, 2021, President Biden announced his ambitious plan to deploy 30 gigawatts (GW) of offshore wind power – enough energy to power 10 million U.S. homes – by 2030. The plan would leverage authorities under the Department of Interior, Energy, and Commerce to guide “more than $12 billion per year in capital investment in projects on both U.S. coasts, create tens of thousands of good-paying, union jobs, with more than 44,000 workers employed in offshore wind by 2030 and nearly 33,000 additional jobs in communities supported by offshore wind activity.” The U.S.

A New Generation of WTIVs

WTIVs have always been fuel-hungry. Now they are being tasked with installations that are further, deeper and heavier.Offshore wind farms continue their march into deeper water, further from shore, with turbines that can now reach more than 270 meters high with blades 120 meters long. Designers and OEMs are pushing efficiency to new levels to contain OPEX on the new-generation jack-up WTIVs taking them up there.Danish ship design firm Knud E. Hansen has chosen specialization for its Atlas A-class WTIV, a smaller derivation of its massive C-class design.

Huisman to Deliver 3,000mt+ Crane for Havfram Wind's New WTIV

Dutch crane maker Huisman has won a contract from offshore wind installation contractor Havfram Wind for the delivery of a 3,000mt+ Leg Encircling Crane for its second NG-20000X Wind Turbine Installation Vessel. The crane contract news comes just a day after Havfram Wind said it had ordered the WTIV from China's CIMC Raffles.Also, Huisman's contract follows an earlier order in December 2022 for an identical crane to be installed on the first vessel.The full electric LEC will be…

Survivors of Libya Shipwreck Brought Ashore in Italy

Seventeen migrants rescued after the latest deadly shipwreck in the Mediterranean were brought ashore by the Italian authorities on Monday as Italy faced criticism for its response to the crisis.Those rescued were taken to the Sicilian town of Pozzallo, Italian newswire ANSA reported, and said they were all originally from Bangladesh.Thirty people were feared drowned after the boat they were traveling in from Libya capsized in bad weather on Sunday, Italy's coastguard said.The tragedy follows a Feb. 26 shipwreck near the southern region of Calabria, in which at least 79 people died.

Thirty Migrants Missing in Shipwreck off Libya. Charity Blames Italy

Thirty people are missing and 17 were rescued in the central Mediterranean on Sunday after the boat in which they were travelling from Libya capsized in bad weather, Italy's coastguard said.The tragedy comes just weeks after a Feb. 26 shipwreck near the southern region of Calabria, in which at least 79 died. Alarm Phone, a charity that picks up calls from migrant vessels in distress, assumed the 30 people were dead and blamed Italy for not sending its coastguard despite being repeatedly alerted on Saturday that the boat was in trouble."Clearly…

Singapore Bunker Premiums Set for Bumpy Recovery in March

Premiums of marine fuel, also known as bunkers, are set for a bumpy recovery in March in Singapore, the world's largest bunkering port, as refuelling demand from the shipping sector has recently waned, multiple trade sources said.A weaker Singapore bunker market reflects slowing activity at one of the world's most major ports that sits on a crucial shipping lane, while lower demand will also weigh on Asia's fuel oil refining margins.Bunker premiums for the most actively traded very low sulphur fuel oil (VLSFO) grade…

KENC Engineering Snags Key U.S. Offshore Wind Contract

KENC Engineering B.V. received a contract from an undisclosed party to design and build a Hammer Quick Lifting Frame. For hammering operations during the construction of two US offshore wind farms, KENC has the assignment to design and build a Hammer Quick Lifting Frame (HQLF). The HQLF integrates a Balltec quick connect receptacle and a 750mT piling hammer. The scope includes installation aids for easy onsite assembly. The tool will be delivered in Q1 of 2023 and deployed in the summer of 2023.

EnCap Backs Houston-based Firm to Build Jones Act WTIVs

Houston-based Bleutec Industries, a company which describes itself as the builder, owner, and operator of Jones Act-compliant offshore wind turbine installation vessels, said Thursday it had secured "a significant capital commitment" from EnCap Investments L.P.Bleutec said the support from EnCap would enable the company to develop its Jones Act wind tubine installation fleet "quickly."“Partnering with EnCap, a strategic capital provider with a strong track record facilitating portfolio company growth…

Yemen's Houthis Increase Pressure with Oil Port Attacks

Yemen's Houthi group is piling on pressure to extract economic gains in U.N.-led talks for an extended truce deal with attacks on oil ports in government-held areas, which officials say have disrupted crude exports, choking state revenues.Yemen's foreign ministry said in a statement that the Houthis launched a drone attack on the southern Qena port in Shabwa on Wednesday. The group's military spokesman said on Twitter that the operation "foiled an attempt to loot" Yemen's oil by preventing a vessel from docking.A joint statement by the U.S.…