Hydrex Conducts Underwater Repair of Bent Container Ship Propeller

In December, Hydrex demonstrated their ability to mobilize anywhere in the world, carrying out a complex underwater propeller repair on a container vessel at anchorage off Pointe Noire, Republic of Congo.Following reports of a possible grounding incident, an underwater inspection revealed deformation to all six blades of the vessel’s fixed-pitch propeller. With no immediate access to drydock facilities in the region and schedule commitments to maintain, the company was contacted…

Wind Assisted Propulsion Installed on Jumbo Jubilee

Two mechanical sails have been installed on board Jumbo's heavy lift vessel (HLV) Jumbo Jubilee. The wind assisted ship propulsion (WASP) solution is the latest in a series of innovative technologies installed to the vessel in a bid to boost fuel efficiency and cut carbon.Jumbo is committed to advancing sustainable heavy-lift shipping with innovative energy-saving and decarbonization initiatives across its fleet, said Jumbo Maritime CEO Daan Kornneef.“At Jumbo, we believe that every step towards sustainability is crucial.

Thordon Bearings Unveils New Shaft Solution for Sterntubeless Ships

Representing a breakthrough in the evolution of a ship’s propeller shaft line, Canada’s Thordon Bearings has unveiled the Thordon-Blue Ocean Stern Space (T-BOSS), a new solution designed to meet the propeller shaft requirements of the sterntubeless ship design proposed by the Blue Ocean Alliance.The Blue Ocean Alliance is a consortium of industry partners – ABS, Thordon Bearings Inc, Wärtsilä, SDARI, and the National Technical University of Athens (NTUA) – that have collaborated…

Efficiency Gains from Eliminating the Hub Vortex

There is hydrodynamic solution that delivers multiple benefits for ship owners facing increasingly tough regulatory requirements and rising operational costs, writes Dr. Batuhan Aktas*One area of ship operations that has attracted much attention in recent years due to the possibilities it represents for emissions reduction is that of cavitation. During ship operations, cavitation occurs because of vortices that build up and cause bubbles to collapse under the ship’s propeller. The results of this process include increased noise, vibration and energy usage.

Partners Aim to Produce 3D-printed Propeller

ABS is joining Mencast Marine (MMPL), the Singapore University of Technology and Design (SUTD), and the National Additive Manufacturing Innovation Cluster (NAMIC) on a project to manufacture and class a 3D-printed propeller.The collaborative project builds upon a memorandum of understanding (MOU) signed by ABS and MMPL that is focused on additive manufacturing (AM), also known as 3D printing, for critical maritime components.The new initiative has an objective to 3D-print a ship propeller using Wire Arc Additive Manufacturing (WAAM) techniques with a goal to achieve high-quality…

Tech File: Ship Propeller Cleaning with Non-Abrasive Diver Tool

DynaFlow's underwater jet cleaning diver tool is designed to reduce propeller fouling removal maintenance time and without being abrasive to the propeller blades.The company second generation Dynajets Non-Abrasive Diver Tool (NADT) is designed to be small, lightweight and quiet.The NADT uses resonating and cavitating jet nozzles in a rotating head housed in a shroud that protects the surface being cleaned and reduces the noise. The NADT was shown to remove propeller fouling including…

Underwater Propeller Repairs in Winter Conditions in Europe

In just over a week Hydrex diver/technicians traveled to Finland, Germany, the Netherlands and France to assist shipowners with damaged propeller blades. On two bulkers the blades were cropped while on a third bulker and a general cargo vessel the bent blades could be straightened.In all cases the best solution was offered to the customer to restore the propeller’s efficiency as close to the original condition as possible.One of the propeller blades of a 180-meter bulker was severely bent. A fast, on-site solution to restore the propeller’s balance and efficiency was needed.

KONGSBERG propeller Blade Air Emissions Tech for silent seas

Kongsberg Maritime has successfully adapted a propeller concept used in naval applications and is now offering the same operational and environmental benefits to commercial shipping customers.While the naval sector has been using KONGSBERG Blade Air Emission technology for a number of years, with several navies deploying it to limit vessel signature, the process is now being applied to commercial ship propellers to reduce the effect of underwater radiated noise on marine life.By machining a channel into the leading edge of the propeller blades…

Fire Breaks out on USCG's Polar Star

It seems the U.S. cannot do enough to fast-track the construction of its new icebreaking fleet, as the USCG announce last night that the 150-member crew of the U.S. Coast Guard Cutter Polar Star fought a fire at approximately 9 p.m. PST Feb. 10 that broke out in the ship's incinerator room about 650 miles north of McMurdo Sound, Antarctica.After initial response efforts using four fire extinguishers failed, fire crews spent almost two hours extinguishing the fire. Fire damage was contained inside the incinerator housing…

World First: Printed Hollow Prop Blade

French defense contractor Naval Group and French elite engineering school Centrale Nantes have printed the first demonstrator of hollow propeller blades by metal additive manufacturing as part of the European H2020 project, RAMSSES.Naval Group, formerly known as DCNS, said that this collaborative program, funded by the European Commission, aims to reduce the environmental impact of ships.Centrale Nantes and Naval Group are taking the lead within this project on the production of innovative propeller demonstrators to improve the operational capabilities of ships.In order to improve vessel propulsion, Centrale Nantes and Naval Group are using additive manufacturing to design large parts (propellers of 6m in diameter)…

Coast Guard's Only Heavy Icebreaker Arrives at Antarctica

The 150 crew members of the U.S. Coast Guard Cutter Polar Star arrived Thursday in Antarctica along with a resupply vessel during Operation Deep Freeze – a joint military service mission to resupply U.S. interests in Antarctica.Homeported in Seattle, the 42-year-old Coast Guard cutter is the United States’ only operational heavy icebreaker, and the crew is making their sixth deployment in as many years to directly support the resupply of McMurdo Station – the United States’ main…

Fouling Control on Workboats

![(Biofouling photo - U.S. Navy photo by Mass Communication Specialist Seaman Apprentice Christopher Frost/Released [A sailor scraping barnacles from the bottom of a rigid-hull inflatable boat aboard an aircraft carrier.])](https://images.marinelink.com/images/maritime/w200h200c/biofouling-photo-us-navy-photo-90895.jpg)

As the domestic offshore energy industry stirs ever so lightly, the task of reactivating long-dormant vessels – some with extensive hull fouling – will become Job ONE. That’s easier said than done.Care and Preservation of Ship Hulls: Workboats vs. Deepwater VesselsNever before has there been such a wealth of data on the processes relating to the fouling of ship hulls. The formation of biofilms and subsequent micro- macro-and bio-fouling has been examined in minute detail and the…

HHLA Transports Ship Propeller for Hyundai Supreme

Hamburger Hafen und Logistik AG (HHLA) loaded the biggest ship propeller in the world onto a vessel. The “HHLA IV” floating crane brought the gigantic 110-tonne object to the port of Waltershof, where it was hoisted onto the “Hyundai Supreme” container ship.It was the most powerful ship propeller to have ever been lifted by the hook of a HHLA floating crane. Although HHLA regularly loads the specialised products of Mecklenburger Metallguss GmbH (MMG) onto ships in Hamburg, the latest propeller, with a weight of 110 tonnes and a diameter of 10.50 metres, surpassed anything that had ever been seen at the port before.MMG is a leading manufacturer of ship propellers.

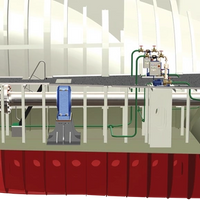

Gibdock Completes Complex BWTS Retrofit

Gibraltar-based Gibdock has been gearing up to meet increased shipowner demand for ballast water treatment system (BWTS) retrofits and has recently completed a complex BWTS retrofit on board the 179m, 34,500dwt bulk carrier Zambesi.The 2013-built, DNV GL classed vessel, owned by Hamburg-based John T. Essberger, arrived in Gibraltar on June 4 for a month-long overhaul program. The vessel departed the yard on July 5 with its new ballast water treatment installed and ready for commissioning, having spent 16 days in Gibdock’s No.

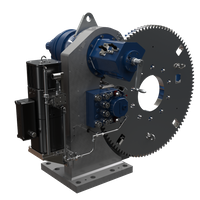

Dellner to Launch New Braking System at SMM

International brake supplier Dellner Brakes AB said it will launch new range of ‘plug and play’ electrohydraulic braking systems at this year’s SMM in Hamburg.The new BUEL STL systems provide a compact, self-contained solution for stopping, turning and locking ship propeller shafts on vessels of all sizes, as well as for industrial applications. They are the first to combine technologies from Swedish-based Dellner Brakes and new sister company, Germany’s Pintsch Bubenzer, which the Dellner Group acquired in January this year.As the name suggests…

Fairbanks Morse's Diesel Gensets for US Navy’s New Warship

Fairbanks Morse, an EnPro Industries company, will supply the Ship Service Diesel Generator (SSDG) sets for electric power generation system aboard the U.S. Navy’s newest America class amphibious assault warship, LHA 8. Construction of the generator sets will begin later this year. They are scheduled to be delivered to shipbuilder Huntington Ingalls Industries in Pascagoula, Miss., in 2019. The six generator sets, powered by 12-cylinder Colt-Pielstick PA6B diesel engines will deliver 24 MW of electrical power and are some of the largest medium speed diesel engines built in the United States. Fairbanks Morse also supplied SSDGs for power generation systems aboard two other ships in the America class – the USS America (LHA 6)…

WAAMpeller: World First Class-Approved 3D Printed Ship’s Propeller

A consortium of organizations are working toward a landmark achievement in the maritime sectors: creating the world's first class-approved 3D-printed ship's propeller. As many sectors of the shipbuilding industry suffer due to overcapacity, it is this type of innovative leap that will -- if successful -- separate the next generation of leaders in the sector. In the effort a cooperative consortium of Damen Shipyards Group, RAMLAB, Promarin, Autodesk and Bureau Veritas aim to develop the world’s first class approved 3D printed ship’s propeller, dubbed WAAMpeller.

MAN Diesel & Turbo, MM-Offshore Partner

At a signing ceremony on June 1 at the Nor-Shipping trade fair in Norway, engines manufacturer MAN Diesel & Turbo signed a cooperation agreement with ship equipment supplier MM-Offshore. The impetus for the agreement stems from industry efforts to enhance ship performance. These have resulted in highly efficient propulsion and maneuvering systems with both now optimized – individually – essentially to perfection. He added, “A number of recent projects have already documented how beneficial such a combined optimization could be for ship designers…

Moving Ahead Powerfully

The layout of ship propellers is a balancing act between optimal power conversion and the avoidance of unwanted cavitation effects, which can result in damage to the propeller structure and higher noise levels. MAN Diesel & Turbo in Frederikshavn, Denmark, is using the computational fluid dynamics (CFD) simulation solution STAR-CCM+ from Siemens PLM Software to model cavitation and optimize ship propellers. Two mid-size container ships of 8,500 TEU – CSCL Europe and CSCL America – will be upgraded by retrofitting a efficient Kappel propeller.

3D Printed Ship’s Propeller Prototype Produced

A prototype of the world’s first class approved ship’s propeller manufactured using 3D printing techniques has been produced by a cooperative consortium of companies that includes Damen Shipyards Group, Rotterdam Additive Manufacturing LAB (RAMLAB), Promarin, Autodesk and Bureau Veritas. The 1,350mm diameter propeller – named WAAMpeller – was fabricated from a Nickel Aluminium Bronze (NAB) alloy at RAMLAB in the Port of Rotterdam. The propeller was produced with the Wire Arc Additive Manufacturing (WAAM) method using a Valk welding system and Autodesk software.

Man Overboard Prevention and Recovery

More than 80 maritime professionals attended two one-day events focused on the sub IMO / sub 80-ft. sector in Southampton, U.K. this Spring. The Man Overboard Prevention & Recovery Workshop brought together an international group of experts armed with the latest knowledge to identify problems that affect the maritime sector worldwide. Workshop lead John Haynes opened the day saying said, “Expectations, requirements and capabilities are changing for many maritime organizations. High profile roles are evolving close to shore and offshore in U.K., European and international waters.

First Class Approved 3D Printed Ship’s Propeller Unveiled

The world’s first Class approved 3D printed ship’s propeller, the WAAMpeller, has been unveiled following rigorous testing verified by Bureau Veritas at Damen Shipyard Group’s headquarters in the Netherlands. The groundbreaking propeller is the result of collaboration between RAMLAB, Promarin, Autodesk, Bureau Veritas and Damen, who started pooling collective resources and knowledge to develop the world’s first 3D printed ship’s propeller seven months ago. Promarin provided the design of the triple-blade propeller.

Century-old Tall Ship Goes High Tech

The 1914-built three-masted steel bark Statsraad Lehmkuhl is the oldest of the large square riggers still in operation today. The century-old tall ship, which is currently in use as a Norwegian sail-training ship, will be able to cruise out of Bergen harbor next year without any greenhouse gas emissions, thanks to a hybrid power system from Rolls-Royce. Norway’s state-owned company Enova, which works to facilitate the country’s transition to a low-emissions society, is providing just over NOK 4.2 million for an innovative project to equip the historic tall ship with shipboard battery power.