Tech Files: Breathing New Life into Old Port Cranes

Retrofits of new features into existing ports cranes can produce operational efficiency and safety gains not included on cranes delivered 15-20 years ago, including Ship-to-Shore (STS) Rubber Tyred Gantry (RTG) and Rail Mounted Gantry (RMG) types. Here, Dmitry Lapin, Knowledge and Development Manager, Port Services, Konecranes, looks at retrofit options proven in applications internationally.Sooner or later, the owners of ports cargo handling equipment are going to face a number of technical and organizational questions about the future.

Kalmar Rolls-out New Automation System

Kalmar, a provider of cargo-handling solutions and services to ports, introduces Kalmar One, the first open automation system for container terminals.Kalmar One is a modular and scalable system that provides a robust foundation for automating container handling operations regardless of the vendor, equipment type, operation mode or automation level at the terminal."Kalmar One is the next step on our journey to promote openness in our industry. We want to speed up the industry transformation by offering a standardised system that allows customers to change the automation level of their operations at a pace that suits their business," says Antti Kaunonen…

Tech Majors Join Forces for Smart Port

The terminal automation and energy-efficient cargo handling services provider Kalmar and Finnish operator Ukkoverkot have signed a two-year co-operation agreement with Nokia for the design, construction and operation of a private LTE network for Kalmar.Nokia brings the digital automation platform that is well suited for mobile machinery and industrial Internet of Things.A test network reflecting an actual terminal environment will be built for research and development purposes. Machine-to-machine communication will be tested in the new private 4G/LTE (Long Term Evolution) environment and compared against previous wireless technologies with the focus on developing innovative business applications.

Dublin Get Kalmar AutoRTG Cranes

The cargo handling solutions and services provider, Kalmar has concluded an agreement with Dublin Ferryport Terminals (DFT) to extend the Kalmar AutoRTG system at the terminal with two new AutoRTG cranes.The order was booked in Cargotec's 2019 Q2 order intake, with delivery of the machines scheduled to be completed during Q2 of 2020, Kalmar, part of Cargotec, said. Part of the container and terminal division of Irish Continental Group, DFT operates the most modern container terminal at Dublin Port, with an annual throughput of approximately 380,000 TEU. The order forms part of DFT's ongoing investment programme focused on ensuring the terminal is equipped with the latest technologies to support future growth.

Asia to Witness Container Terminal Automation Boom

Kalmar Automation Solutions said that the share of automated terminals will grow rapidly in Asia, given the terminal operators’ interest and activity level towards automation.Container terminal automation in Asia is in an early stage, except for Australia. First automated mega-terminals are in operation and future growth depends on many external issues. In general, Rubber-Tyred Gantry crane (RTG) is the main handling system for containers globally, and that applies in Asia as well.RTG is used in 60% of the main container handling systems for 420 main terminals in Asia. However, when counting the number of container moves completed in different terminals, RMGs/ASCs dominate. This is because the big container terminals use RMGs/ASCs but in general, they are a minority.

Kalmar Bags Bilbao Forklift Order

Terminal automation provider Kalmar, part of Cargotec, has concluded an agreement to supply Servicios Logisticos Portuarios SLP, a leading cargo-handling operator at the Port of Bilbao, Spain with a total of five heavy-duty forklift trucks.The order was booked in Cargotec's 2019 Q1 order intake, with delivery scheduled to be completed early in Q3 of 2019, said a press release from the provider of cargo-handling solutions and services to ports and terminals.The customer already operates a number of older Kalmar forklifts at Bilbao and appreciates their reliable performance. The five new units will primarily be used to handle steel mill products such as plates and coils.Ignacio De Sebastian…

Konecranes Wins Abu Dhabi Terminal Automation Deal

Abu Dhabi Terminals (ADT) has selected Konecranes to be the supplier of an Automated Stacking Crane (ASC) system for the second phase of the building of its container terminal in Khalifa Port: the Khalifa Port Container Terminal (KPCT).This is an order for a total of 54 Automated Rail Mounted Gantry (ARMG) cranes. The parties involved have agreed not to disclose the value of the deal. The order will be booked in Q4 2018.Konecranes earlier successfully delivered 52 ARMG cranes, on time and on budget for the first phase of KPCT container terminal, which went live on 12/12/12. The second phase involves a large expansion of the terminal area, infrastructure, container handling capacity, and the delivery of 54 Konecranes ARMGs.

Kalmar-Navis Intermodal Automation Solution for Moorebank Logistics Park

Kalmar, part of Cargotec, and Navis, part of Kalmar Business Area within Cargotec, have been awarded the contract to supply a state-of-the-art, fully automated intermodal terminal solution for Qube's Moorebank Logistics Park (MLP) in south-western Sydney. The order, valued at approximately EUR 80 million, includes the supply of the OneTerminal solution comprising Kalmar's automated train handling, automated yard crane and automated horizontal transportation equipment and the Navis N4 terminal operating system (TOS). It was booked into Cargotec's 2018 second quarter order intake. The manual operations at the Moorebank facility are due to commence in Q1 of 2019.

Kalmar Key's Open Interfaces for Terminal Automation

Kalmar has announced Kalmar Key, the terminal industry's first automation platform with open interfaces. Kalmar Key provides a common system architecture for building an end-to-end, customised automation platform using Kalmar Terminal Logistics System (TLS) as a basis. The product opens the application-independent core software components of the Kalmar terminal automation system for use by developers, enabling terminal operators to extend their automation systems with any brand of equipment. By providing open application interfaces to the core functionality of the automation system, Kalmar aims to facilitate the adoption of container terminal automation and support the development of the entire industry.

US West Coast Not Ready for Mega Boxships

CMA CGM is testing the ability of the U.S. West Coast ports to handle the biggest containerships – are they ready? U.S. West Coast ports are not yet in a position to handle 18,000 teu containerships regularly and have much work to do in terms of improving productivity if they are to see them call on anything other than an ad-hoc basis. The 18,000-teu CMA CGM Benjamin Franklin will become the largest containership to call at any U.S. port when it arrives at the port of Los Angeles on 26 December. The new ship was delivered to French carrier CMA CGM at the start of the month and will join the Asia-U.S. West Coast ‘Pearl River Express’ service, part of the Ocean Three network, that normally operates with seven ships of around 11,400 teu.

Kalmar to Debut its latest at TOC Europe Exhibition

Kalmar, part of Cargotec, will introduce yet another port industry first during the upcoming TOC Europe exhibition in Rotterdam, the Netherlands. On 9 June, ONE is coming. Automation is widely accepted as the way towards improved productivity, safety and competitiveness in today's container terminals. However, it is often perceived as a difficult task that requires terminal operators to integrate multiple complex systems. "We believe that the port industry is at the start of the next big wave of automation. Kalmar and Navis, as global technology leaders in this field, are strongly contributing to this transformation and addressing the industry's challenges.

MOL President Reports Slack Performance

MOL President, President, Koichi Muto reported that the performance of the company was slack. Muto reported, "I am sad to report that our business performance fell short, and we could not achieve our initial target of ¥70 billion in consolidated ordinary income. Looking back at FY2014, the containership business could not achieve our targets despite the favorable winds of a depreciating yen and lower bunker prices. This was due to factors including inaccurate projections regarding the trade environment, freight rate market, and bunker prices, as well as construction delays in our terminal automation project, and led to a significant loss. In addition, repeated downward revisions of our forecasts have eroded shareholders’ trust in our company.

Kalmar Completes AGV Project at PSA Singapore

Kalmar, part of Cargotec, has successfully completed the project to supply the onboard navigation application for four automated guided vehicles (AGVs) to PSA Singapore. The initiative is part of PSA's strategic investment in automation technologies to enhance its premier status as the world's largest transhipment hub. The project included the design of the AGVs' onboard navigation system, the navigation infrastructure and the deployment of Kalmar SmartFleet remote diagnostic tools. The installation and integration to vehicle systems were started in the autumn of 2013, and the navigation application was fully integrated with PSA Singapore's in-house systems by the end of 2014.

US Port Congestion Hides Deeper Issues

Ports on the U.S. West Coast are currently suffering from chronic congestion, but are there deeper issues affecting their performance? Drewry’s new report Container Terminal Capacity and Performance Benchmarks compares capacity and performance benchmarks for 500 terminals worldwide that help to explain some of the underlying factors hindering ports in North America. The severe congestion currently affecting U.S. West Coast ports is a consequence of a “perfect storm” of factors working together, Drewry said.

Port of Long Beach Chooses APS Crane OCR System

APS Technology Group, a member of the ABB Group and a leading provider of optical character recognition (OCR) and process automation technology solutions for marine and intermodal container terminals, says that that International Transportation Service (ITS) has selected the APS Crane OCR solution for its terminal in Long Beach, Califormia. APS explains that ITS chose its solution to improve system accuracy, resource utilization and ultimately customer service of the terminal. The new Crane OCR system automates the process of identifying and verifying ISO containers loaded and discharged from dockside Ship-to-Shore (STS) gantry cranes with high accuracy, redundancy and unequalled reliability.

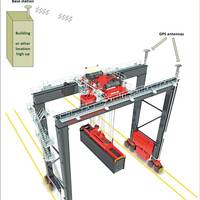

Port of LA's TracPac RMG Cranes to be Integrated by Kalmar

Kalmar, part of Cargotec, has been awarded a contract for the integration of the controls for the new rail mounted gantry (RMG) cranes at the intermodal yard of TraPac Inc's terminal at the Port of Los Angeles. Kalmar explain that the RMGs will be supplied to TraPac by PACECO with the Kalmar Terminal Logistic System (TLS) ensuring they are integrated in the automated operations. TLS is part of the Kalmar SmartPort equipment automation portfolio. The intermodal yard is a substantial part of the terminal, with 30 percent of the TEUs shipped inland by rail.

TWIC’s Last Hurdle is Scaled

Card reader technology is tested, proven and in use, nationwide. While the maritime industry awaits the Fed’s edict on MTSA, the solution already exists. The Maritime Transportation Security Act (MTSA) requires that individuals needing unescorted access to MTSA-regulated Facilities and Vessels must first obtain a TWIC. To obtain a TWIC Card, an individual must meet certain eligibility requirements and pass a security threat assessment conducted by the Transportation Security Administration (TSA). Individuals are then issued a tamper-resistant credential containing the cardholders biometric fingerprint data, which provides a conclusive link between the card and the individual cardholder. To date, more than 2 million of these credentials have been issued.

Atsec Fixed Reader Passes TWIC Trials

Atsec announced the successful test of Schneider Electric’s PC3-TBR reader against the specifications set forth by the TWIC Reader Evaluation Program. Before vendors can sell their products to be used in the TWIC program, they have to undergo independent testing. As an accredited laboratory under the National Voluntary Laboratory Accreditation Program (NVLAP), atsec is qualified to test TWIC readers for conformance with the program requirements. According to Schneider Electric’s executive VP Smart Infrastructure Division Ignacio Gonzalez, "As one of the first vendors to undergo testing for a TWIC reader, Schneider Electric is a pioneer of the new program. atsec has been an excellent partner in the process and their test engineers are highly competent.

Port of LA: Huge Capital Investment Program Approved

The Harbor Commissioner's Fiscal 2013-14 Budget Includes $399.9-million capital expenditure to improve cargo flow and dfficiency. The Los Angeles Harbor Commission has adopted a 2013-14 fiscal year (FY) budget of approximately $1.1 billion for the Port of Los Angeles, including one of the largest annual Capital Improvement Programs -- $399.9 million or 37% of the total budget -- in Port history. The budget supports more than 8,500 jobs, 6,870 of which are attributable to construction project spending in the coming fiscal year which begins July 1.

ABB Acquires APS Technology

ABB acquires APS Technology Group to expand its Crane and Harbor systems portfolio; acquisition expands ABB’s portfolio for container terminal automation to optimize cargo handling and tracking from ship to gate. ABB, a leading power and automation technology group, has agreed to acquire APS Technology Group (APS), a San Diego, California-based company that develops and markets solutions for the port industry. The acquisition will expand ABB’s crane system portfolio to the container terminal market. The transaction is expected to close in the first quarter of 2013. Established in 2002, APS employs approximately 50 full-time people in its headquarters in San Diego, California, and its office in Long Beach, California.

Cargotec Gets Major Order from DPWorld Brisbane

Cargotec receives an order to deliver 14 Kalmar automatic stackingcranes & 14 Kalmar one-over-one shuttle carriers to DP World Brisbane Pty. The equipment will be taken into use at the Port of Brisbane. DP World Brisbane will also be using Navis Sparcs N4 TOS in their Brisbane terminal expansion. Deliveries of the equipment are scheduled for 2013 and early 2014. The parties have agreed not to disclose the transaction value. "The Port of Brisbane is the fastest growing port in Australia and is therefore of key significance to DP World. Cargotec's package delivery of cranes and the ease of integration with Navis terminal automation solution…

APS Technology Group Enters Brazilian Market

APS Technology Group, Inc., a provider of optical character recognition (OCR) and process automation technology solutions for marine and intermodal terminals, announced its entry into the Brazilian market with the award of a terminal automation project at Tecon Suape S/A in Recife, Brazil. Tecon Suape, a member of ICTSI Group, is implementing the APS solutions to support volume growth, reduce operational costs and to meet the Customs mandate to install OCR at its gates. Tecon Suape expects to increase its movement capacity to an annual throughput of 1.5 million containers. This project represents the second in Latin America for APS within the ICTSI group, including Contecon Guayaquil SA (CGSA) in Guayaquil, Ecuador.

APS Terminal Automation at Dames Point

APS Technology Group (APS) announced that TraPac, Inc. will deploy several of APS' terminal automation solutions at its new container terminal at Dames Point in Jacksonville, Florida. The 158 acre facility will include 6 post-panamax quay cranes, 6 Rubber Tired Gantry (RTG) cranes and an 18-lane automated gate complex. The project includes APS solutions to automate the identification and check-in of containers, chassis and truck license plates at each gate lane. In an effort to provide a safer working environment, TraPac will also become the first East Coast terminal to deploy OCR automation within its vessel and yard operations. Here APS will provide its Crane OCR and MatchMaker systems, which automatically identify containers and internal tractors at each quay crane and RTG.