ONE Orders 12 Methanol Dual-Fuel Containerships

Japanese shipping company Ocean Network Express (ONE) has signed shipbuilding contracts with Jiangnan Shipyard and Yangzijiang Shipbuilding for the construction of 12 13,000 TEU methanol dual-fuel containerships.Each shipyard will build six vessels and are all scheduled to be delivered from 2027. The order represents ONE’s inaugural fleet of methanol-dual fuel vessels and plays a key role in reaching ONE’s sustainable goals as part of its green strategy."Our decision to invest in methanol-dual fuel vessels aligns with ONE's Green Strategy as part of our key initiatives.

MHI Develops Oilless, Nitrogen-Based Cryogenic ORC Generator

Mitsubishi Heavy Industries has demonstrated a 100kW class cryogenic organic Rankine cycle (ORC) power generation system using a nitrogen-based, oilless cryogenic turbine generator.ORC systems are able to harness lower-temperature heat than typical waste heat recovery systems, and MHI says the use of liquid nitrogen as the cryogenic energy source provides a stable refrigerant cycle and the specified regeneration output without freezing-induced clogging. It performs well even under…

James Fisher’s Second Dual-fuel Vessel Enters Service

James Fisher and Sons plc announced it has taken delivery of its second 6,000dwt LNG dual-fuel tanker, Lady Maria Fisher, which will be traded by James Fisher Everard (JFE) alongside its existing fleet.Built and launched at China Merchants Jinling (CMJL) shipyard in Yangzhou, China, the vessel is currently transporting cashew nut shell oil from Vietnam to Europe, where it will then be processed into bio-diesel.The newbuild and sister vessel Sir John Fisher delivered in November 2022 will replace two of James Fisher’s existing tankers and will be able to carry more cargo.

World's Largest Cruise Ship Floated Out in Finland

Finland's Meyer Turku shipyard has floated out what it says is the world's largest and Royal Caribbean International’s most environmentally friendly cruise ship, Icon of the Seas.During the upcoming weekend, the ship will be moved to the outfitting dock, where its now fully assembled hull will be finished into "a magnificent cruise ship" during next year."Outfitting of the ship is a challenging job, the end result of which is to build an unprecedentedly versatile vacation possibilities on the ship.

Region in Focus: Norway’s West Coast Shipping Tech Hub

Two load-bearing pillars of Norway’s leading maritime industry cluster in Sunmøre on the country’s west coast – offshore energy and the expedition cruise sector – took severe knocks from plunging energy prices in the 2010s followed by COVID-19. However, a recent tour of the region found the cluster in recovery mode.At the time, the cluster’s diversification strategy was to dive into the emerging expedition cruise sector: small, highly sophisticated ships designed to operate in some of the world’s most sensitive environments incorporated features including the highest ice-class…

Mitsubishi, Wärtsilä Joins for Improved Power and Propulsion Solution

Mitsubishi Heavy Industries Marine Machinery & Equipment Co., LTD (MHI-MME) and the smart technology group Wärtsilä have signed a Memorandum of Understanding (MOU) regarding the commercial marketing of a new energy solution for ships. The solution combines innovative technologies from both companies to produce greater power generation capacity and higher propeller propulsion for marine vessels. By integrating MHI-MME's waste heat recovery and energy saving power generation system (WHRS) with Wärtsilä's operational control technology for shaft generator systems, the new solution results in more energy efficient ship navigation and an improved Energy Efficiency Design Index (EEDI).

ABB Steps Up Marine R&D with New Lab

Next generation of maritime technology will be developed with ship owners at high technology facility in Helsinki, Finland. Power and automation group ABB has upped its commitment to research and development in the marine sector by opening a new laboratory in Helsinki, next to the Azipod factory, aiming to bring together all the company’s offerings for the shipping industry under one roof. ABB said it has invested significant funds in the scheme, which will be used by the 30 ABB engineers dedicated to marine research in Helsinki as well as to demonstrate products to customers.

ABB Wins Contract from Chinese Shipyard

ABB announced that it will deliver advanced electrical propulsion systems for four LNG carriers under construction by Hudong-Zhonghua Shipbuilding (Group) Co., Ltd. The LNG vessels are a joint venture between China National Offshore Oil Corporation (CNOOC), China LNG Shipping (Holdings) Limited (CLNG) and Teekay, and will operate under 20-year time-charter contracts with Methane Services Limited, a wholly-owned subsidiary of BG. LNG carriers are highly sophisticated in terms of technology and are specially designed to transport LNG at a low temperature of minus 162 degrees Celsius. They are regarded as the “super freezer cars of the sea” and “the pearl on the crown” in the world shipbuilding industry.

Ecoships Claims 15% Ship Efficiency Gain

Ecoships introduced a customized version of the Six Sigma DMAIC approach to process and performance evaluation in order to optimize the energy-efficiency of the vessels under its management. The technique has already resulted in Ecoships’ managed ships benefiting from up to 15% greater fuel efficiency, resulting in substantial reductions in CO2, NOx and SOx emissions. “We specialise in eco-friendly and fuel-efficient shipping tools, techniques and technologies,” said Capt. Aykut Yilmaz, GM. “Our three primary goals are safety, fuel efficiency and minimum ecological impact.

New Bulk Carrier Design Puts Ecoships in the Lotus Position

Ecoships, the technical shipmanagement arm of Newport Shipping Group, has introduced a next generation bulk carrier design, developed to set the standard in ecologically compatible marine transportation. Inspired by the low friction to water flow and self-cleaning properties of the lotus flower – a symbol of purity and beauty in Buddhist and Hindu philosophy – Ecoships’ Greenlotus 32, is a 32,500dwt geared, wide hatched, handy-size bulker, designed to meet existing and future CO2 (carbon dioxide) NOx (oxides of nitrogen) and SOx (oxides of sulphur) emissions regulations.

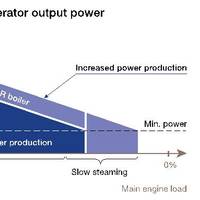

Pressurized EGR Boiler Ready For Testing

Exhaust Gas Recirculation (EGR) has firmly shown its ability to comply with Tier III NOx limits, which will enter into force in January 2016. Developed by MAN Diesel & Turbo, the EGR process already relies on Alfa Laval’s PureNOx, which provides the vital cleaning of the scrubber water. Now Alfa Laval is cooperating with MAN Diesel & Turbo to implement an EGR boiler, which could potentially add major energy benefits to the secure emission compliance. Over 1000 hours of EGR operation have now been achieved aboard the Maersk Cardiff, a container newbuild from A.P.

ABB Wins $23 Million Orders for 14 Containerships

Power and automation technology group ABB won two orders in the third quarter to provide the waste heat recovery systems, each powered by a power turbine generator (PTG), for 14 new 8,800 TEU (twenty-foot equivalent unit) container vessels. The first seven post-panamax vessels will be built at Dalian Shipbuilding Industry Co. Ltd., (DSIC) and the other seven vessels at New Times Shipbuilding Co. Ltd., for China International Marine Containers Group Co. and Mediterranean Shipping Co. S.A (MSC).

IMO MEPC Implements Further Energy Efficiency

The Marine Environment Protection Committee (MEPC) of the International Maritime Organization (IMO) met for its 65th session from May 13-17 2013, at IMO Headquarters in London. The committee made significant progress in its work on further developing energy-efficiency regulations; adopted an MEPC resolution on rromotion of technical cooperation and transfer of technology relating to the improvement of energy efficiency of ships; and gave the go-ahead to carry out an update to the greenhouse gas (GHG) emissions’ estimate for international shipping.

Alfa Laval Tumba AB at Nor-Shipping 2013

Taking place June 4-7 at Norges Varemesse in Oslo, Nor-Shipping is an international forum for Northern European maritime industry. At the Alfa Laval stand in Hall E, visitors will find a comprehensive approach to easing financial and regulatory pressures, with solutions for energy efficiency and extending performance at the forefront. Today’s marine industry faces difficult and conflicting challenges, especially when it comes to energy. As rising fuel prices and shrinking margins create a push to reduce fuel consumption…

Alfa Laval Aalborg WHR Systems Ordered for UAS Fleet

Alfa Laval Aalborg to supply XS-TC7A auxiliary engine waste heat recovery (WHR) economizers to all 48 ships in the United Arab Shipping (UAS) Company fleet. With its small footprint and the lowest possible weight to output ratio, the Aalborg XS-TC7A economizer optimizes the use of waste heat from the auxiliary engine exhaust gases during voyage and port stays. When used in combination with a waste heat recovery system installed after main engine, the Aalborg XS-TC7A contributes to significant reductions in the oil consumption on the oil-fired boiler under most load conditions.

New Alfa Laval Waste Heat Recovery System

The Aalborg XS-TC7A waste heat recovery (WHR) economizer from Alfa Laval is designed specifically for a ship's auxiliary engines. Waste heat recovery systems after the main engines have proven lucrative for decades for many ship owners, says Hans-Henrik Jensen, Alfa Laval Vice President, Marine & Diesel Division. Taking advantage of the waste heat from a ships auxiliary engines is the natural next step, which is now possible thanks to the Aalborg XS-TC7A. Firing the auxiliary…

WHR Improves Fuel Efficiency and Cuts Emissions

Hard pressed to boost profits in light of rising fuel costs and stricter emissions regulations? Ship owners will find welcome relief in the new Aalborg XS-TC7A waste heat recovery (WHR) economizer from Alfa Laval. Designed for use after a ship’s auxiliary engines, this innovative waste heat recovery system promises fuel and emissions savings for the world’s maritime fleet. Firing the auxiliary boilers to sustain a ship’s steam requirements now costs much less – both in terms of fuel oil and impact on the environment – thanks to the Alfa Laval Aalborg XS-TC7A.

GL & MAN Publish Joint Study on LNG as Fuel for Container Ships

Using liquefied natural gas (LNG) as ship fuel has recently gained more attention not only in Europe, but also in Asia and the USA. New, stringent regulations are forcing the shipping industry to rethink its fuelling options. Emissions controls, introduced by the IMO’s Marine Environment Protection Committee, combined with the introduction of emission control areas in European, U.S. and Canadian territorial waters, will have a profound impact on international shipping over the next ten years. LNG is an attractive alternative to conventional marine fuels. Can the use of LNG as marine fuel help the industry to meet these challenges? In this web-special GL looks at this potentially game changing technology…

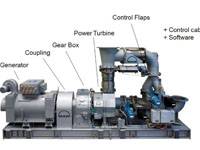

First Marine Application for New Generation TCS-PTG

MAN Diesel & Turbo received an order for two Turbo Compound Systems including Power Turbine and Generator (TCS-PTG) from Samjin Shipbuilding in Weihai, China. The TCS-PTGs will be employed aboard two 4,700 TEU container vessels currently under construction, operated by German shipowner Reederei Horst Zeppenfeld, each powered by individual MAN B&W 6S80ME-C9.2 low-speed engines. The order includes an option for two extra vessels. The order represents the first such instance for…

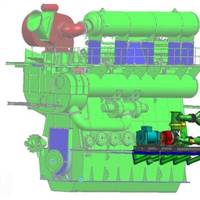

MAN Diesel & Turbo Improves WHR Systems

MAN Diesel & Turbo used the world premiere of its MAN B&W ME-GI gas engine in Copenhagen to present efficiency technologies for its twostroke engines, namely its WHR (Waste Heat Recovery) systems, that include its TCS-PTG turbines, and which are offered as an integrated solution. WHR exploits exhaust-gas energy and is designed to be used in the production of electricity to cover a ship’s electrical needs. All ME- and MC- types in MAN Diesel & Turbo’s engine portfolio are suitable for WHR where, generally speaking, the greater the engine output, the greater the potential WHR offers. As a result, WHR technology has traditionally been applied to container-ship and power-station applications.

Alfa Laval Acquires Aalborg Industries

Alfa Laval – a leader in heat transfer, centrifugal separation and fluid handling –signed an agreement to acquire Aalborg Industries Holding A/S for a total cash consideration of $729.6m, on an enterprise value basis, from Altor 2003 Fund, LD Equity and the Company’s management. Aalborg Industries has some 2,600 employees and is expected to generate sales of about $481.5m in 2010. The acquisition will be accretive to EPS from 2011. The closing of the transaction is subject to clearance from regulatory authorities. Headquartered in Aalborg, Denmark, the company is a provider of products, systems and service solutions, today mainly to the marine and off-hore markets, but it also has an increasing exposure to the power industry as well as to other industrial end markets.

Merger Complete: MAN Diesel & Turbo SE

The merger announced between MAN Diesel SE and MAN Turbo AG to form MAN Diesel & Turbo SE, based in Augsburg, is now complete, the corresponding entry having been made in the register of companies. The process of amalgamating the two former MAN sister companies into one enterprise has thus been achieved. In economic terms, the merger has come into effect retroactively as of 1 January 2010. By combining the complementary product portfolios of the two firms, the merged company will be striving for growth and looking to strengthen its position in the relevant market segments. “The merger now having become effective, the MAN Group will be seeking to pool its expertise in large bore diesel engines and power plants with its strengths in compressor and turbine technologies…

London Places Power Turbine Order

H. Cegielski – Poznan S.A. has ordered two MAN Diesel TCS-PTG18 Power Turbine systems from MAN Diesel’s Turbocharger Business Unit. The TCS-PTGs will boost the efficiency of two environmentally friendly, diesel power plants to be constructed by Land & Marine for renewable energy company Blue-NG in London. A H. Cegielski-built MAN B&W 7K60MC-S engine producing 13.9 MW lies at the heart of each plant. Blue-NG is committed to being best in class at building the most efficient power plants in the world…