Design’s Future 3D Modeling, Virtual Reality Wave of Design Future

Rooted in early computer-aided design (CAD) and manufacturing applications, design and construction software is firmly at the helm of most shipyards today, enabling the production of better designed, more efficient and consistently built ships produced with measurably less waste: less waste of time, materials, man hours and most important, money. The ROI can be substantial, and is traceable throughout the entire process, across all sub sectors such as project management, purchasing, materials, labor and build sequencing.

For example, in terms of production planning, “the same outfitting job being done in the workshop, when done at dry dock or in the final stages can cost up to 15 times more. The customer tells us that the more you can anticipate in the early stages, the more money you save,” said Stephane Neuveglise, Product Business Manager at Aveva Group plc.

Rafael de Góngora, General Manager of Sener Marine, agrees “It’s a matter of money: The earlier the decisions have the greatest economic impact.”

It’s estimated that virtually all first- and second-tier shipyards use some form of naval architecture and construction software – ranging from the old man of the design software market, rudimentary AutoCad, to more sophisticated versions of Autocad and even more feature-rich products offered by the small cluster of companies that dominate the market.

Key players include Sener, Aveva, SSI and Dassault Systemes.

In the first piece of this three-part series on ship-building technologies, last month we looked at how the movement of naval architecture from paper to computers has dramatically impacted and changed the process of ship design and construction for the better, where those changes have taken place, and what the payout for shipyards has been [MREN August 2014, “Soft Solutions: The Evolution of CAD/CAM].

This month’s installation will take a closer look at some of the providers of the technology driving down the need for costly rework orders and in some cases, responsible for eliminating tedious and error-prone tasks of yesteryear, and talk to them about the changes they see cresting above the market.

SENER

To hear Sener Marine GM de Góngora tell it, competitors are many in the market for ship design and construction software – and they fall into one of two distinct camps: Ship design software, and general, typically AutoCAD-based CAD software that can be used for ship design.

“In the first group, we are not so many; maybe half a dozen, if we speak about companies with some importance,” says de Góngora, positioning Sener as one of the three main vendors in the ship design CAD software market, and tagging UK-based Aveva as one of its main competitors. In the second group, the number of competitors is greater, and increasing.

FORAN, Sener’s venerable offering in CAD ship design, was introduced in 1965 and will celebrate its 50th anniversary next year – an astounding milestone for any piece of software, especially today in an era where application life cycles often run three years or less. It is estimated that FORAN has been involved in the design and construction of over 1,000 vessels worldwide. It is currently used in more than 150 ship design offices and shipyards in 30 countries.

Longevity is actually one of the attributes of de Góngora‘s “first group.” The key players in the ship design application market – Sener (58 years/Spain), Aveva (47 years/UK) and Dassault Systemes (33 years /France) - are all long-time players, with British Columbia-based SSI the youngest, notching 24 years in the business.

Also key to several of these players is a background in naval architecture and marine engineering. Like Aveva, Sener, for example, was founded by a marine engineer, Enrique de Sendagorta, and initially focused solely on marine projects. The company over time expanded into other industries, but its core ship design software was developed by Sener architects seeking to solve their own problems. Eventually, the company realized that it had a product that could be sold to other architects and ship yards, leading to FORAN’s debut.

Of course, as de Góngora notes, the FORAN of yesteryear has nothing in common with the system the company is currently marketing, which was most recently updated in July (FORAN V7OR3.0). The technology has changed, obviously - think three-dimensional (3D) and virtual reality - but more important, the design process has changed as well

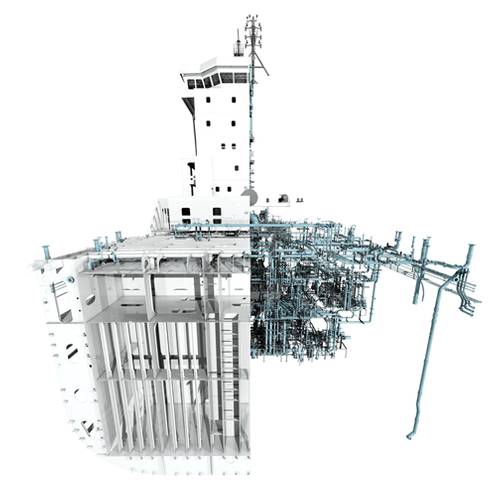

FORAN today is an integrated CAD/CAM/CAE system that can be used in the design, production and manufacture of ships. Subsystems run the gamut from hull structure to machinery, to outfitting, electrical and drafting and mechanical designs. “Expert add-ons” include a PLM link, virtual reality and Control Management. All information is stored in an Oracle database. Among other changes, the most recent version enables the visualization of the ship 3D model already generated in FORAN into a virtual reality environment, two areas Sener and it’s competitors see as key to the future.

The Windows-based system comprises several application packages, a number of common modules (build strategy, 2D drafting, 3D walk-through design review, concurrent engineering), links with production equipment, interfaces to management systems and an integrated development environment. There are two major lines of business: the design of ships and marine structures, and the development of FORAN, its design and construction software that now boasts worldwide commercial success.

Key to FORAN’s endurance, believes de Góngora, is its ability to provide a single solution from the first stage of the design to the complete assembly and delivery of ship, without requiring the assistance of any third-party software. While the company doesn’t provide product lifecycle (PLM) management, it does provide a link to those products. “We are the only one who can provide a single solution,” de Góngora claims.

The transformation of the industry, meanwhile, during FORAN’s expansive lifespan, has been “dramatic,” resulting in measureable benefits, according to de Góngora. “One benefit is time. This is very important in the ship building industry. We have shorter delivery times compared with 25 years ago, because the time required to build, assign and construct is much shorter.”

This, despite the added complexity in ships being designed today. Even in the face of more complex ships, CAD design packages help ship builders to continue to win the race for shorter delivery times. More complex operations of the ship require more complex technology. And that complexity in a product, says Aveva’s Neuveglise, helps drive the need for more 3D. For example, the more equipment in a given space, the more you need to be able to see in 3D to be able to navigate the area, and the earlier in the process the modeling is done, the better.

“Doing more in the same space of time is actually an advance,” says SSI CEO Darrell Larkins, adding that today, it’s not so much about being able to do the same thing more efficiently, but rather, about the ability to do more. Put another way, he said, “Software might let you do something a thousand times faster when what you are really trying to accomplish is 1,000 times more complex.”

On top of the savings in time, shipyards can achieve a significant reduction in materials waste and cost because design software enables accurate fabrication information and in essence, guarantees no interferences. Scrap from construction of parts is then reduced to minimum.

So what kind of ROI are we talking about? “If you are in a shipyard that is not highly tech-oriented, you could see savings of 30% to 50%. If you take into account a state-of –the-art shipyard, the improvement is less. We are speaking about 10% in worst cases. But this is something. Ten percent in the price of a ship is many millions of U.S. dollars,” says Sener’s de Góngora.

Another way to tackle waste and push consistency is to enable information about modifications and the data collected in the PLM system to be sent back up the information chain into the computer-aided process planning (CAPP) system from the PLM package, something Sener and Aveva are working on.

“If you are building more ships of one class, the second ship is almost equal. The third and fourth are not the same – some modifications will have been made.” Transferring those changes back down the line will enable those modifications to be made to subsequent ships far more easily, notes de Góngora.

Sharing that data more quickly, “I guarantee there will be more consistency between the phases of design than before,” said Neuveglise

This is where Aveva touts the benefits of adopting the concept of lean manufacturing from the auto industry. Invented by the founder of Toyota, lean manufacturing is about how to be more efficient in production. It is based on no waste, respect of everyone and their job, and a continual feedback loop at all levels. It’s the concept of providing feedback from production back to the design stage that really intrigues Aveva.

“Sometimes when doing a detailed design, you find something that is not easy to do, or which needs to be further fabricated. So production tells the guys in basic design, ‘Don’t do that anymore for future reference,’ ” says Neuveglise. It’s even more important in shipbuilding because unlike automobile manufacturing, which is designed and built sequentially, in ship building, it’s all done at the same time, which makes the process much more complex. “So if something is discovered in the detailed design phase, you need to tell the folks in basic design, and until recently, we weren’t able to have this kind of feedback,” he adds.

That will change in the next generation of ship design processes as software will need to address two issues, in de Góngora’s view:

• Collaborative design on a global level. “The ship building industry is a paradigm of globalization,” he says, noting that the design, various parts of the ship, the basic ship, the owners and suppliers typically are spread out around the world. “We need to keep working on a collaborative solution for all these geographically-dispersed partners.”

• Increased use of 3-D software, which traditionally is used more in product design, than in the earlier stages of the design. “This is important because the most important decisions in design are made at the earliest stage where you are defining all the main parts of the ship.” All the decisions you make at that stage have consequences,” said de Góngora.

SSI

Sener won’t get any argument from SSI, which is a big proponent of 3-D software and any form of communication that leads to better design decisions made earlier in the process. In an April blog post, CEO Larkins crowned communications as “the most significant contributing factor to the success of ship yards.” By which he means all the steps involved in the effective creation, sharing, dissemination and management consumption of information. “The shipyards who are good at determining not only how and when information will be shared, but also where, why and with who . . . are more effective and more successful,” he explained.

In fact, SSI, formerly known as ShipConstructor Software Inc., is all about three things:

• Proudly Open Architecture. Notes CTO Denis Morais in a July post, “I love the idea of keeping ShipConstructor 100% purely open and competing with our competitors solely on benefit to the users. There is not a single piece of information that ShipConstructor hold hostage in a proprietary format.’’ SSI walks the walk on Open Architecture with its membership and participation in programs and study projects at the US National Shipbuilding Research Program (NSRP), The Autodesk Developer Network, Autodesk University, VIATeC, SNAME and RINA.

• Fostering better communication, collaboration, and information flows, as early and frequently as possible, with its customers, and between the various stages of ship design and production, as noted above in Aveva’s embrace of lean manufacturing.

• And getting customers to understand that it’s not just knowing what information to gather and where it’s located, but knowing why you are providing it that is really key. Over engineering, or too much information, can cloud an otherwise clear piece of instruction, and lead to mistakes that will have to be reworked.

The company is trying to move itself into more of a consultative relationship with its old customers and newer off shore clients. According to Larkins, SSI wants to look at the bigger picture a bit more, taking on issues like managing information flow while increasing its focus on providing services.

Spend a little time perusing the company’s various blogs written by SSI executives, including Larkins, and the shift to bigger picture thinking is clear. And they want their clients thinking too. In particular, Larkins likes to “lift the curtain” on SSI’s popular ShipConstructor package, and explain the business and technical thinking behind and impact of, the changes, approaches and upgrades in the product line, or point to an issue driving those changes, and talk about how to address it.

The company provides a lot of avenues through which customers can seek support or provide feedback, and recently added one more: Client Councils, which gather together user representatives from narrow industry sectors and regions, to advise the company on addressing their specific requirements. “Both technology and industry requirements are evolving quickly so our clients continually need to adapt,” said SSI CTO Denis Morais.

The initial Client Council consisted of Vripack, Peters Shipyards, Royal Huisman, Vera Navis, Marine Technologies Ltd., BMT Nigel Gee, Mustang Marine, Skipskompetanse, and Pendennis. Some of the groups’ requests were featured in the new release: the split plate command, a new fillet cut type for stiffener end cuts, increased pipe and HVAC connection tolerance, and the ability to create MarineDrafting views in other types of drawings. That’s the kind of response that engenders loyalty.

Ship Constructor seems to turn up everywhere, often at shipyards and architectural practices that have been with the product since its early days as CADLink in the late’80s. Joe Comer, principal of Ship Architects, Inc., claims to have bought the first ShipConstructor license from founder Rolf Oetter in 1988, moving his design process off a mainframe onto a PC. Comer still uses ShipConstructor today. According to the company, the majority of U.S. Naval warships are now built with the SSI solutions. The U.S. Coast Guard also has taken notice, according to Morais, and is asking for ShipConstructor –compatible deliverables on bids for its OPC Program. SSI’s flagship product, ShipConstructor serves the shipbuilding and offshore industry, and is an AutoCAD-based 3D Product Modeling and Production Planning CAD/CAM suite running on Microsoft’s SQL Server. When announcing his appointment as CEO, Larkins stressed the company’s commitment to delivering tools that are user friendly, scalable, easily adopted and implementable with minimal IT requirements. SSI combines support for the native DWG platform with industry-specific standards, terminology and best practices, and the ability to share engineering data with other business processes and applications such as MRP, ERP or PLM tools. The company claims that ShipConstructor’s Marine Information Model provides true Concurrent Engineering for the first time in shipbuilding CAD/CAM, enabling all engineering disciplines to work within a single integrated environment with associativity that extends to the production drawing level. A side benefit of SSI’s support for Autodesk and other standards is that ShipConstructor is said to require little training and gives client a much broader labor pool.

AVEVA

Cambridge, England-based Aveva provides a family of integrated engineering design and 3D design, CAD products. The 45-year-old company is also focused on offshore clients, concurrent engineering and global collaboration. It sees its mission as enabling the creation and management of complex digital assets, allowing customers to work globally with less risk, shorter lead times and greater business efficiency throughout the lifecycle of their physical assets.

AVEVA Marine is a set of integrated applications provides engineering design and information management software to the marine and plant industries. This combination provides a level of technology integration, enabling collaboration with plant industry specialists on the most complex vessels or offshore projects, concurrent engineering, and supports highly collaborative “global virtual’’ shipyard’ projects.

Its naval architecture and hull design capabilities have been developed over more than 30 years in partnership with many of the world’s leading shipbuilders. AVEVA Enterprise offers specialist shipyard resource management capabilities enabling an efficient and integrated shipbuilding process, from initial concept to final handover.

Aveva MARS is an enterprise resource management (ERM) package with modules including Material, Planning and Production.

Last month, Aveva launched Aveva Information Standards Manager (ISM), which governs asset information using a standards-based methodology.

This is the 2d in a three-part series on Ship design and construction. Next month, the final piece will examine the fleet management and operations software market, and how those applications can help owners and operators successfully reduce and control costs while protecting profit margins.

(As published in the September 2014 edition of Maritime Reporter & Engineering News - http://magazines.marinelink.com/Magazines/MaritimeReporter)