Designing the New National Security Multi-Mission Vessel

For more than 100 years the U.S. has depended on State Maritime Academies (SMA) to produce USCG licensed merchant officers. The SMA’s have also been an important source of U.S. Navy and U.S. Coast Guard officers, as well as trained personnel for the maritime industry and electric power industries ashore. Key to training these future deck officers and engineers has been the annual sea cruise on dedicated training vessels.

- SAFETY: It was decided jointly by HEC and MARAD that the ships should be fully compliant with safety regulations and requirements for a ship carrying up to 760 persons, both international regulations and U.S. Coast Guard regulations and ABS Class Rules. This was a goal of the design even though as a U.S. government owned vessel documented as a Public Nautical School Ship, there was no legal requirement to meet SOLAS.

- SIZE: A key design constraint was that the ships fit within the pier length and draft restrictions at the five SMAs and operate at no more than 25 ft draft for access to smaller and less developed ports in support of HA/DR missions.

- LEAN & GREEN: Another design goal was for the ships to be efficient and economical to operate and also environmentally friendly. This goal is met by incorporating features such as full time operation on clean burning, low sulfur fuel, use of engine waste heat for accommodation heating, efficient LED lighting, and hull lines optimization for low propulsion power. LNG fuel was not adopted because the vessel’s intermittent operation made managing LNG fuel onboard difficult and the lack of regular routes makes it impossible to ensure a reliable supply of LNG. The hull lines optimization by CFD methods and model testing, carried out by model basin SSPA in Sweden, was effective in reducing required propulsion power by about 10% between the concept design and the optimized hull design.

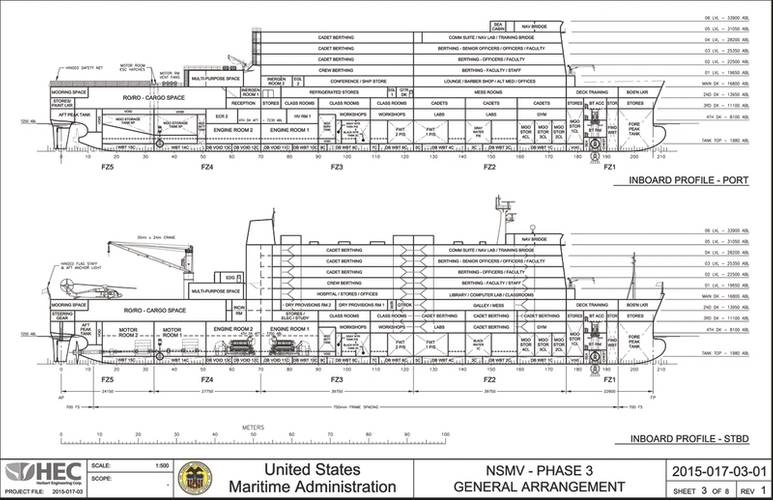

- FORM & FUNCTION: A lot of the arrangement design was driven by the design goal to have a coherent and interconnected training ship environment while still providing practical and useful HA/DR mission capability. Meeting diverse requirements required focus on meeting key priorities and finding ways to integrate requirements into the same spaces. Some of the ways this was accomplished are as follows:

a. While HA/DR mission requirements are important to the design, they should not overly interfere with training ship capability. This was accomplished by focusing the HA/DR cargo carriage in the after part of the vessel and having the training ship spaces centered in the middle part of the ship to allow quick and easy access between all spaces. In this way berthing spaces are kept convenient to the mess, class and training facilities.

b. Berthing is provided for 700 persons in normal training ship mode, with 600 cadets and 100 non-cadets. An important quality of life feature and to make it easier to recruit persons to serve on the vessels, all 100 non-cadets have private cabins with private toilet and shower facilities. The goal was also to reduce the number of large cadet berthing areas compared to the existing ships. This is achieved by berthing 384 cadets in the accommodation deckhouse in four-person cabins, each with a separate toilet and shower unit. The remaining 216 cadets are in the typical 3 high berths located in the hull, but these spaces are convenient to class rooms and mess areas. During HA/DR missions, it was identified that there may be a need to increase persons onboard by 60 to a total of 760. This requirement is met by installing two high berths in some of the non-cadet cabins, so while these normally accommodate one person, in surge periods they can accommodate two persons.

c. The food storage, food preparation, food service, and mess areas are on the same deck and arranged for catering and service efficiency. This was an important requirement from the SMA’s.

d. Redundancy is provided as required by safety regulations and to continue essential services in case of a fire or flooding casualty in any one area. Safe return to port is possible even in case of loss of the main propulsion system, up to and including the main shaft and propeller. This is achieved by use of a drop down azimuthing bow thruster that can propel the ship at speeds over six knots.

e. Two separate engine rooms are provided for reasons of redundancy in an emergency and to allow training to take place in one engine room while the second is used for propulsion. This is feasible on training cruises because the ships generally operate at slower speeds, around 12 knots, since the purpose is to be at sea and not to quickly reach a port.

f. Required training spaces are incorporated into the design, including eight class rooms, navigation lab, computer lab, several cadet workshops, simulator spaces and other laboratory spaces. A separate training bridge is located one deck below the main bridge with full visibility forward and equipped similarly to the main bridge so cadets can experience navigation of the vessel without interfering with actual safe navigation.

g. HA/DR mission capability includes transport of general cargo, containers, vehicles and trailers on the aft open deck area and in the enclosed RoRo space below that. A cargo crane, also useful for training, and a RoRo side ramp are provided to make the vessel self-unloading. Larger medical facilities than required for a training ship are provided and these can be easily expanded, including loading of medical modules on deck and in RoRo spaces with utility hookups provided. Ability to land helicopters, a key HA/DR mission requirement, was met by making the open aft deck also a helicopter landing area, but without capability to refuel or maintain helicopters.

h. During HA/DR missions, it is necessary to keep key personnel berthing and command and control areas secure. This was accomplished by placing these areas in the forward half of the deckhouse and allowing this area to be kept secure by locked doors.

i. The vessel is able to maneuver and moor without tugs, considered useful for HA/DR missions when ports may be disrupted by a crisis, and this capability reduces vessel operating costs during normal cruises.

- TOPSIDE: The need for open deck cargo space and a RoRo deck led to several challenges. It was determined that placing them aft would result in the least interference with the primary training ship mission, however, this created a structural challenge with locating the large side ramp opening. It was desired to have a more forward ramp location so when it was in the up position it would not interfere with helicopter landing, but the full ship and fine mesh finite element analyses (FEA) carried out identified high stresses if this were done. The solution was to relocate the ramp aft and install a folding ramp with a low profile in stowed position, minimizing its interference with helicopter landing. The transition of the large deckhouse to the open main deck aft also created structural challenges that were identified using the FEA. Modifications to reduce stress concentrations included fitting large transition brackets at the aft end of the house and separating the multi-purpose space house, located aft of the deck house, from the main deckhouse and engine casing to free the connection from hull bending stresses.

- Herbert Engineering was the project lead and lead on arrangement, structure, systems, machinery, stability, and regulatory compliance design. Assistance was received from Carl Setterstrom, consultant naval architect.

- Jamestown Metal for galley and mess design and training space and cabin layout.

- SPAR Associates for cost estimation.

- SSPA, Sweden, for hull lines optimization, model testing and propeller design

- VT Group for IT infrastructure design

- B. Rosenblatt & Associates for accommodation piping systems and machinery space arrangements.

Bow Thruster: retractable combi type - tunnel thruster in up position, azimuthing thruster in down position, “Take Home” source of power, 1450 kW