Ballast Water Tech: Optimarin

As ship owners globally face the eventual mandate to install ballast water management technology onboard their ships – a refit which is touted as the most expensive equipment refit ever – Maritime Reporter & Engineering News in its February 2013 edition examines emerging Ballast Water Technologies for consideration.

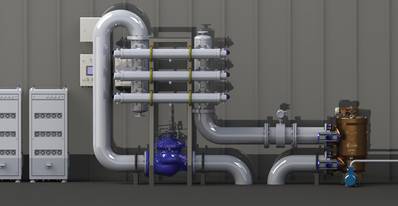

Optimarin is a Norwegian company with a strong pedigree in the Ballast Water Management market, offering its Type-Approved Optimarin Ballast System (OBS) based on solid separation (filter) as pre-treatment and high doses of UV irradiation for inactivation of marine organisms, viruses and bacteria, without affecting the normal operation of the ship. Ballast water is UV treated both during ballasting and de-ballasting to ensure the dual UV effect. Ballast water is only filtered during ballasting.

A highly touted plank in the OBS solution is the fact that it does not use or generate chemicals or biocides in its treatment or cleaning processes. OBS is designed as easy to install on board existing ships (retrofit) as well as on newbuilds, a modularized system with a relatively small footprint and weight, able to be delivered as a complete skid or as a customized solution. It accommodates a wide range of ballast water capacities and can handle flows up to 3000 cu. m./hr. (or higher upon request).

The Optimarin Ballast System is normally installed in the pump or engine room and in close proximity to the ballast pumps. The OBS can be delivered in a container, on a skid or in separate pieces to allow for easy installation in most any available space.

In fact, according to CEO Pål Sanner, it is the unit’s small size and flexibility of install that will help drive business for the company. “Serious players in the (shipping) market are the ones that will plan ahead and not get caught up in the (BWMS) bottleneck,” said Sanner. “We feel we are well positioned for the retrofit market due the small footprint of the system and our ability to mass produce.”

Most recently the company announced a deal for three orders by Siem Offshore to supply OBS 150 cu. m./hr. systems based on Ballast Safe filter as to be installed during dry dock. This order gives Optimarin a reference list with a total of 208 sold systems.

www.optimarin.com

(As published in the February 2013 edition of Maritime Reporter & Engineering News - www.marinelink.com)