The Power of Offshore Molecule Production

Energy ecosystems are evolving as the value of offshore power-to-X production is being realized.

Flexible and delivered in long lengths on reels in a fast-track operation, thermoplastic composite pipeline can transfer up to nine times the amount of energy as a cable and can be used to store hydrogen, increasing the uptime of offshore wind farm generated power.

That’s according to Netherlands based supplier Strohm, member of the Hydrogen Offshore Production for Europe (HOPE) project and the Dutch floating green hydrogen and ammonia OFFSET project. It’s one of the reasons why an increasing number of European clean energy projects are looking at the production of green hydrogen and power-to-X fuels such as ammonia on floating platforms.

In a study of the North and Baltic Seas, DNV concluded that the lower costs of hydrogen transmission compared to electricity and the possibility for large pipelines to aggregate offshore hydrogen production from several windfarms, makes offshore hydrogen production an attractive option for offshore wind farms, certainly at distances of more than 100 kilometers from shore.

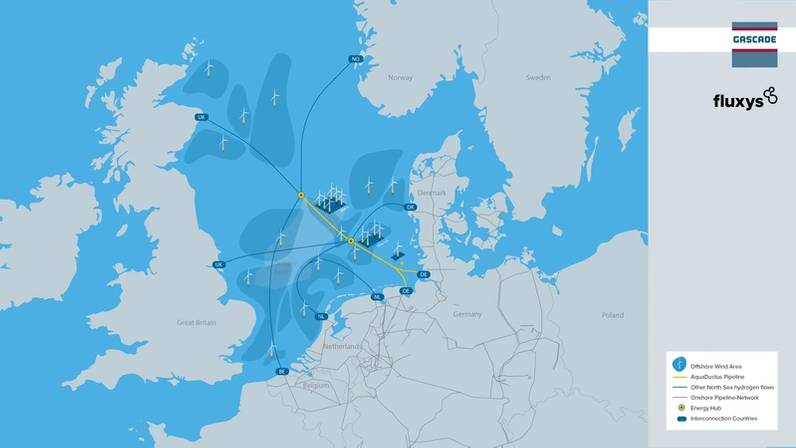

The alternative is shipping molecules to shore, and Maciek Lukawski, VP of Strategy & Business Development for ammonia power solutions company Amogy, points out that, for locations like Japan, Europe and the US with limited shallow waters and strong interest in ammonia, floating production platforms will enable strategic access to clean ammonia. “Transportation of green ammonia through shipping can provide widespread access in the near future rather than the development of offshore pipelines.” Amogy has signed MoUs with Southwind to promote offshore wind development and Marco Polo Marine to develop its ammonia-to-power solution for deployment on OSVs. The offshore AquaDuctus pipeline will be over 400 km long when completed. Image courtesy of Fluxys.

The offshore AquaDuctus pipeline will be over 400 km long when completed. Image courtesy of Fluxys.

Shipping will still involve new piping solutions. Earlier this year, H2Carrier and Trelleborg Gas Transfer signed an MoU on ship-to-ship ammonia transfer systems that will be based on Trelleborg’s KLAW LNG technology and upgraded to operate with liquid ammonia.H2Carrier has developed the P2XFloater for floating production of green hydrogen and ammonia. The concept is based on oil and gas technology combined with an e-control system capable of balancing renewable electricity feedstock through a fully integrated electrolyzer and Haber-Bosch synthesis system. The hull could be a newbuilding or a retrofitted very large gas carrier.

Mårten Lunde, CEO of H2Carrier, says the design solves a number of concerns for renewable energy projects: cost, time, use of land and environmental footprint, and lengthy planning and regulation processes. The P2XFloater can be positioned anywhere renewable energy costs are low, resulting in the production of extremely cost competitive green ammonia. “We plan for a near shore operation in the beginning, simply because we are targeting the lowest cost electricity.” Offshore wind is technically feasible, but currently too expensive, he says. H2Carrier has signed a Letter of Intent with Anori for the development of Greenland’s first commercial wind farm and ammonia production and export facility.

Lhyfe is coordinating a 10MW project in the North Sea off the port of Ostend, Belgium, as part of the HOPE project, which will pipe up to four tons of green hydrogen to shore a day. HOPE is the first offshore project of this size in the world to begin actual implementation, with the production unit and export and distribution infrastructure due to come on stream in mid-2026.

In another project, SwitcH2 and BW Offshore, along with partners Strohm, MARIN and TU Delft, are developing an offshore green ammonia FPSO that is both modular and scalable. The initial 300-meter FPSO will be able to produce 790 tons of green ammonia per day at its peak using a 300MW electrolyzer plant.

The FPSO can be moored in shallow waters with a submerged yoke or spread mooring system or in deeper waters a turret system. In areas where there is no or limited offshore pipeline infrastructure, the offloading features of an FPSO makes it suitable for storage and subsequent ship-to-ship transfer.

The electricity powering the FPSO will be imported onboard from an offshore wind farm via high-voltage electrical swivels allowing the unit to naturally weathervane when turret-moored. The FPSO will also use waste heat recovery and harness wave energy.As part of the OffsH2ore project, researchers at the Fraunhofer Institute for Solar Energy Systems ISE, are also aiming for high production. Together with project partners PNE, Silica Verfahrenstechnik, Wystrach, Kongstein, they have developed a design for an 500MW offshore hydrogen production facility powered by offshore wind.

“With the concept presented by the consortium, rapid and large-scale implementation has become realistic,” says the Institute.

Others in Europe are working towards a “backbone” of energy islands and pipeline infrastructure. A study prepared by DNV for GASCADE and Fluxys highlights the advantages of an offshore hydrogen backbone, AquaDuctus, in the North and Baltic Seas. The study concludes that offshore hydrogen production connected by pipeline is cheaper than onshore hydrogen production.

By 2030, the 1GW SEN-1 offshore hydrogen wind farm will be connected to a 200-kilometer pipeline bringing green hydrogen to Germany. From there, it will be piped to European consumers. Pascal De Buck, CEO of Fluxys, says: “The AquaDuctus offshore pipeline, thought of as a regulated open access infrastructure available to all future operators of hydrogen wind farms, will make a substantial contribution to security of supply by diversifying Europe's hydrogen supply sources.”

Siemens Energy is working with 32 partners on the H2Mare project to address, amongst other issues, whether it is better to supply power to offshore power-to-X production facilities as electricity or hydrogen. “You could produce hydrogen at each wind turbine and then combine it at the power-to-X facility, or you could combine the electricity from multiple wind turbines to produce hydrogen on a separate platform and then supply it to the power-to-X platform. It turns out that the former option is better,” said Matthias Mueller, coordinator of the H2Mare project, and Professor Roland Dittmeyer of Karlsruhe Institute of Technology, in a recent IEEE Spectrum article.

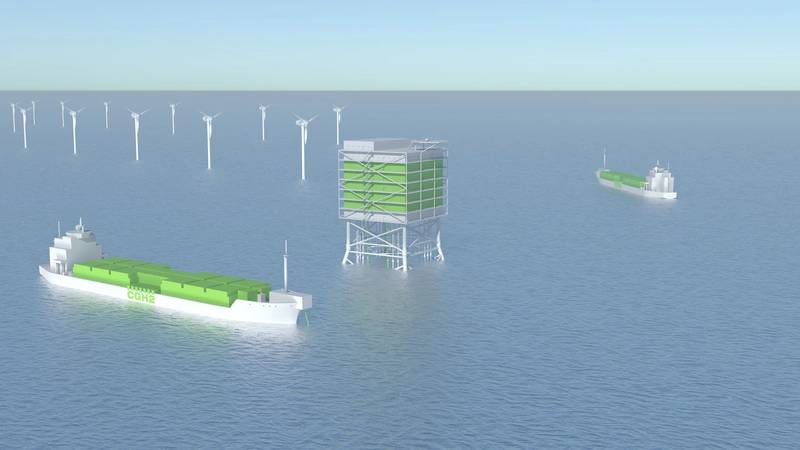

They envisage a future where ships regularly dock at offshore platforms. All the processes would be fully automated and largely self-sufficient. Someday, even the ships themselves might be autonomous. “It seems like science fiction now, but major efforts are already underway to demonstrate the technologies needed to realize this vision.

SwitcH2 and BW Offshore, along with partners, are developing an offshore green ammonia FPSO that will be able to produce 790 tons of green ammonia per day. Source SwitcH2.

SwitcH2 and BW Offshore, along with partners, are developing an offshore green ammonia FPSO that will be able to produce 790 tons of green ammonia per day. Source SwitcH2.